Dry Ice Pack Sheets for Medical Transport: Essential Guide

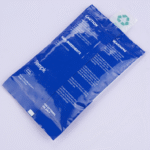

When transporting temperature-sensitive medical products, maintaining a consistent low temperature is crucial. Dry ice pack sheets offer a reliable solution to ensure that medical items, such as vaccines, insulin, and biological samples, stay frozen or chilled throughout transit. This article explores how to select the right dry ice pack sheets for your medical shipments, ensuring safety, compliance, and efficiency.

-

What are dry ice pack sheets, and why are they essential for medical transport?

-

How do you choose the right dry ice pack sheets for your medical shipments?

-

What are the best practices for handling and storing dry ice?

-

How to ensure compliance with safety regulations when shipping medical goods?

What Are Dry Ice Pack Sheets, and Why Are They Essential for Medical Transport?

Dry ice pack sheets are specifically designed sheets made of solid carbon dioxide, used to maintain ultra-low temperatures during medical shipments. With a sublimation temperature of -78.5°C, dry ice is ideal for shipping products that need to stay frozen or chilled, such as vaccines, insulin, and biological materials. These sheets are flexible, making them easy to fit into various container sizes, ensuring that medical goods remain within the required temperature range.

Key Characteristics of Dry Ice Pack Sheets for Medical Transport:

| Characteristics | Description | Significance for Medical Transport |

|---|---|---|

| Temperature Range | -78.5°C | Keeps medical products frozen |

| Sublimation Rate | 5-10 lbs every 24 hours | Ensures extended cooling during shipment |

| Size and Flexibility | Customizable sheet sizes | Fits a variety of containers for optimal cooling |

How to Choose the Right Dry Ice Pack Sheets for Medical Shipments?

Selecting the correct dry ice pack sheets depends on several factors such as the duration of the shipment, the type of medical goods, and the environmental conditions during transit. Here’s a breakdown of the key considerations:

-

Calculate Your Cooling Needs

Before choosing dry ice pack sheets, it’s essential to calculate how much cooling is necessary for your shipment. Larger or multiple sheets are needed for longer shipping durations, especially for medical shipments like vaccines. -

Consider Packaging and Insulation

To maximize cooling efficiency, ensure that the dry ice is packed with adequate insulation. Without proper insulation, the dry ice can sublimate too quickly, compromising the cooling performance. -

Ensure Compliance with Regulations

Dry ice is classified as a hazardous material, and its shipping is regulated by various authorities such as the Department of Transportation (DOT) and the International Air Transport Association (IATA). Make sure your packaging and documentation comply with these regulations.

Factors to Consider When Choosing Dry Ice Pack Sheets:

| Factor | Importance for Medical Shipments | Your Action |

|---|---|---|

| Cooling Duration | Determines how long the products stay cold | Choose the appropriate dry ice quantity |

| Insulation Requirements | Reduces temperature fluctuations | Use insulated shipping containers |

| Regulatory Compliance | Ensures safe transport of dry ice | Confirm compliance with regulations |

How to Safely Handle and Store Dry Ice Pack Sheets?

Handling dry ice requires special care due to its extreme cold. Improper handling can result in frostbite or suffocation due to the sublimation of carbon dioxide. Here are some best practices:

Safety Precautions for Handling Dry Ice:

-

Wear protective gloves and eye protection to avoid injuries.

-

Handle dry ice in well-ventilated areas to prevent carbon dioxide buildup, which can cause suffocation in enclosed spaces.

-

Avoid direct skin contact to prevent frostbite. Always use insulated gloves or tongs.

How to Store Dry Ice Safely:

-

Store dry ice in ventilated containers that allow gas to escape to avoid dangerous pressure buildup.

-

Never store dry ice in sealed containers as the sublimation process can cause an explosion.

-

Keep dry ice in a cool, dry environment to prolong its shelf life and ensure safety.

| Safety Considerations | Description | Your Action |

|---|---|---|

| Ventilation | Prevents dangerous gas buildup | Store in a well-ventilated area |

| Protective Gear | Protects from cold burns or injury | Always use gloves and safety goggles |

| Storage Container | Prevents accidents from gas expansion | Use ventilated, non-sealed containers |

Latest Trends in Dry Ice Use for Medical Transport in 2025

The use of dry ice in medical transport is evolving with new advancements. 2025 is expected to bring further innovations that enhance shipping efficiency and reduce costs.

New Technologies in Dry Ice Transport:

-

Smart Sensors: Modern dry ice packs now come with built-in temperature sensors that provide real-time tracking of conditions during shipment, allowing for better monitoring and ensuring the product stays within the required temperature range.

-

Blockchain for Traceability: Blockchain technology is increasingly used to track the entire shipping process, ensuring the authenticity and integrity of medical shipments.

Market Insights for 2025:

With the rising demand for faster and more reliable medical shipments, the global cold chain market is projected to reach $500 billion by 2025. The medical sector, particularly in vaccine distribution and the transport of biological materials, is driving advancements in cold chain logistics.

Frequently Asked Questions (FAQs)

Q1: How long does dry ice last during shipping?

Dry ice typically lasts 24-48 hours, depending on the size of the pack and environmental conditions during transit. For longer shipments, larger packs or multiple sheets should be used.

Q2: Can dry ice be used for shipping vaccines?

Yes, dry ice is ideal for shipping vaccines that need to be kept at ultra-low temperatures. It’s important to ensure proper packaging to maintain the required temperature during the shipment.

Summary and Recommendations

Dry ice pack sheets are essential for the safe and efficient transport of temperature-sensitive medical products. To maximize their effectiveness:

-

Choose the correct dry ice sheet size based on your shipment’s cooling needs.

-

Use insulated packaging to prolong the life of the dry ice.

-

Follow all safety protocols and regulatory guidelines when handling and shipping dry ice.

Action Steps:

-

Evaluate your shipping needs to determine the right dry ice pack sheet size.

-

Use insulated packaging to extend the cooling period.

-

Ensure regulatory compliance by working with logistics partners familiar with dry ice shipping guidelines.

About Tempk

At Tempk, we specialize in providing reliable cold chain solutions, particularly for medical and pharmaceutical transport. Our dry ice pack sheets are designed to meet the highest standards of safety and quality, ensuring your products are delivered on time and in perfect condition.

Contact Us for more information on how our dry ice solutions can improve your medical shipments.