Dry Ice Wrap Dry Ice Packs: How to Ship Frozen Goods

You can keep products safely frozen with dry ice wrap dry ice packs when you plan heat load and hold time, not just the label. This guide shows you how to size, pack, and ship with confidence. Expect clear steps, simple math, and 2025-ready compliance to cut claim rates and protect margins.

-

How dry ice wrap dry ice packs work and when they outperform gel packs

-

How to calculate quantity with a simple, field‑ready method

-

How to pack for 24, 48, and 72+ hours with fewer temperature spikes

-

Which regulations apply to dry ice wrap dry ice packs by air and ground

-

How costs compare vs gel and phase‑change materials (PCM)

-

2025 trends shaping dry ice packaging and greener options

-

Practical checklists, a decision tool, and a real case you can emulate

What is “dry ice wrap dry ice packs,” and when should you use it?

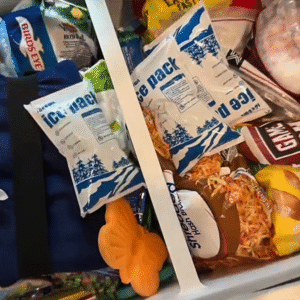

Short answer: Dry ice wrap dry ice packs combine a reflective or insulating wrap around your frozen payload with solid CO₂ packs that sublimate at −78.5 °C. Use this method when you need rock‑solid frozen hold times, tight presentation, and vented packaging for safety. It is ideal for ice cream, meat, seafood, frozen desserts, and certain lab samples. Expect stronger pull‑down and longer hold vs gel packs in the same box volume.

More detail: Think of the wrap as a warm‑coat for your product and the packs as the cold engine. The wrap reduces radiant and convective heat gain; the CO₂ packs absorb heat as they turn from solid to gas. That phase change is powerful and predictable. When ambient temps swing or routes run long, dry ice wrap dry ice packs keep center‑of‑mass colder than gel packs alone. You still need ventilation for the gas, and you should always place packs above the product so cold sinks through. This setup shines in direct‑to‑consumer frozen food, specialty desserts, and weekend‑risk shipments.

How cold, how long, and what affects results?

Key factors: payload size, insulation R‑value, ambient temperature profile, pack placement, and ventilation. A simple rule for planning: colder ambients and thicker walls reduce CO₂ burn rate; hot ambients and big voids increase it. For most small‑parcel boxes, dry ice wrap dry ice packs maintain frozen state for 24–72 hours when sized correctly and vents are kept open. Always test your route with a simple data logger before scaling.

| Hold‑Time Planner | Ambient band (°C) | Suggested dry ice kg per 10 L void per 24 h | Meaning for you |

|---|---|---|---|

| Mild route | 10–20 | 0.8–1.0 | Standard spring/fall shipments need less CO₂ |

| Warm route | 20–30 | 1.0–1.4 | Add buffer for afternoon peaks and depot dwell |

| Hot route | 30–40 | 1.4–1.9 | Use more CO₂, better insulation, or reduce box size |

Practical tips and advice

-

Top‑loading pays: Place dry ice wrap dry ice packs above the payload so cold sinks downward.

-

Vent, don’t seal: Puncture or crack the lid vent. Never use airtight containers for CO₂.

-

Shrink the void: Fill empty space with light inserts so the packs “see” less air.

-

Wrap the product, not the box: The wrap should hug the payload; then add packs and insulation.

-

Test once, copy many: Run one data‑logger test per lane, then repeat the packing recipe.

Real‑world case: A dessert brand shipping pints across three zones replaced gel with dry ice wrap dry ice packs and added top‑loading. With the same box, claim rate fell from 7.8% to 1.6% in July heat. Average product temp at delivery stayed below −12 °C for 60 hours.

How much dry ice wrap dry ice packs do you need for 24–72 hours?

Short answer: Aim for 1.0–1.4 kg of dry ice per 10 L of total internal volume per 24 hours in typical warm routes. For mild routes, start at ~0.8 kg; for hot routes, 1.4–1.9 kg. This field rule gets you close when you do not have a full heat‑balance model.

Planner method you can use today:

-

Measure your shipper’s internal length × width × height to get total liters.

-

Estimate ambient: mild, warm, or hot.

-

Choose a rate from the table above.

-

Multiply rate × (liters/10) × days.

-

Round up by 10–20% if you expect delays or door‑to‑door weekend holds.

Example: 20 L box, warm route, 48 hours → 1.2 kg × (20/10) × 2 = 4.8 kg. Round to 5.4–5.8 kg for buffer. This quantity pairs well with dry ice wrap dry ice packs arranged in a top layer with vented lid.

Field calculator you can copy

Pro tip: If your payload must stay rock‑hard (e.g., −18 °C ice cream), add a small vapor barrier around the wrap. It slows frost and keeps cartons clean when dry ice wrap dry ice packs sublimate.

How do you pack with dry ice wrap dry ice packs step by step?

Short answer: Shrink the void, wrap the payload, top‑load CO₂, and vent the lid. Label net CO₂ weight and “UN 1845 Dry Ice.” Use gloves, and never seal gas inside.

Step‑by‑step packing SOP:

-

Pre‑stage the box with a bottom pad and corner inserts to reduce convective currents.

-

Build the wrapped core: Place product in its dry ice wrap dry ice packs sleeve. Remove excess air.

-

Add side insulation so the core fits snugly; avoid large air channels.

-

Top‑load dry ice above the wrapped core; break large blocks into chunks for even flow.

-

Add a vented lid or crack a corner to release CO₂ gas.

-

Mark the package: “Dry Ice (UN 1845), net ___ kg.” Include sender/recipient and emergency phone.

-

Weigh the box with a scale and record net CO₂ for compliance and replenishment planning.

-

Final check: Shake gently. If anything shifts, add dunnage. The colder the route, the tighter the pack.

Layout that reduces “hot spots”

-

Put dry ice wrap dry ice packs on top, then thin pads on the sides.

-

Keep at least 1 cm clearance from outer walls to avoid sweating and cardboard softening.

-

For fragile desserts, add a thin corrugated shelf below the CO₂ layer to spread pressure.

-

Use a bright “Vent Before Opening” sticker to reduce unboxing risk in receiving areas.

Dry ice wrap dry ice packs vs gel packs vs PCM: what should you choose?

Short answer: If it must stay frozen, dry ice wrap dry ice packs win on hold time per liter. Gel packs shine for refrigerated lanes (2–8 °C). Modern PCM at −10 to −21 °C can bridge shoulder seasons but costs more per cycle.

Decision cues you can use:

-

Shipments that must remain below −10 °C → favor dry ice wrap dry ice packs.

-

Temperatures between −5 °C and +8 °C → hybrid with gel/PCM; reduce CO₂ to avoid overshoot.

-

Highly regulated pharma lanes → verify label requirements before picking CO₂.

| Option | Typical temp band | Box efficiency | Cost per shipment | Best for |

|---|---|---|---|---|

| Dry ice wrap dry ice packs | ≤ −10 °C to −78.5 °C | High (strong per‑liter cooling) | Medium–High | Ice cream, meat, seafood, lab specimens |

| Gel packs | +2 to +8 °C or 0 to −2 °C | Medium | Low–Medium | Meal kits, chilled desserts |

| PCM (−10 to −21 °C) | Frozen but not ultra‑cold | Medium | High | Shoulder seasons, lanes with CO₂ restrictions |

What regulations apply to dry ice wrap dry ice packs shipments?

Short answer: Dry ice is classified as UN 1845, Class 9. You must label the package, state the net weight of dry ice in kilograms, and provide ventilation. Air shipments follow airline and IATA rules; ground shipments follow local transport rules (e.g., DOT in the U.S.). Always check carrier‑specific limits.

Essentials you should follow every time:

-

Marking: “Dry Ice (UN 1845)” + net weight in kg + shipper/consignee.

-

Venting: Never seal CO₂ in an airtight container; use vented lids or relief holes.

-

Documentation: Air waybills must reflect dry ice presence; some carriers require a phone contact.

-

Packaging: Use materials that tolerate −78.5 °C and allow gas release.

-

Training: Personnel handling dry ice wrap dry ice packs need basic hazard awareness.

Safety reminder: Use thermal gloves. Avoid vehicle trunks and small unventilated rooms. CO₂ gas is heavier than air and can displace oxygen.

Operations playbook: last‑mile and scale with dry ice wrap dry ice packs

Short answer: Standardize your “recipe,” then lock it into your WMS/TMS so packers, labels, and replenishment all agree. Measure, adjust, and repeat per lane.

Simple playbook:

-

Recipe cards: For each SKU and zone, define liters, route band, and dry ice wrap dry ice packs kilograms.

-

Kitting: Pre‑bundle wraps and CO₂ packs by lane (e.g., “Warm‑48h kit”).

-

Data logging: Spot‑log 1 in 20 boxes; rotate skews during hot months.

-

Depot discipline: Stage boxes under shade; avoid open docks for more than 10 minutes.

-

Exceptions: If a scan predicts weekend dwell, auto‑upgrade the recipe by +15% CO₂ or route to faster service.

2025 trends in dry ice wrap dry ice packs

Trend snapshot: In 2025, more brands aim for curbside‑recyclable liners and lower CO₂ footprints. Expect lighter boxes with higher R‑value per millimeter, better vented‑lid designs, and smarter replenishment powered by route forecasts. Dry ice wrap dry ice packs remain the frozen benchmark, while hybrid PCM strategies grow for shoulder seasons and CO₂‑restricted lanes.

What’s new this year

-

Fiber‑based wraps with reflective films: Greener materials without losing radiant shielding.

-

Bluetooth mini‑loggers under $20: Easy route tests before committing to a recipe.

-

Route‑aware kitting: Auto‑selects “warm” vs “hot” kits on the fly inside the pack app.

Market insight: Customers reward reliable frozen arrivals more than ultra‑low shipping fees. Brands that stabilize product temps and cut damages grow repeat orders. In frozen e‑commerce, a one‑point drop in claims can pay for stronger dry ice wrap dry ice packs recipes across the board.

Frequently Asked Questions

Q1: How long do dry ice wrap dry ice packs keep items frozen?

Sizing drives results. For warm routes, plan 1.0–1.4 kg per 10 L per 24 hours. Vent the lid and top‑load the packs to avoid early warm‑ups.

Q2: How many packs should I use in a small 15 L shipper?

For a 48‑hour warm route, start near 3.5–4.0 kg total, split across several smaller packs for even sublimation and fewer hot spots.

Q3: Can I ship by air with dry ice wrap dry ice packs?

Yes. Label “Dry Ice (UN 1845)” and net kg, provide ventilation, and follow airline rules. Some carriers set per‑package limits and documentation steps.

Q4: Will dry ice affect food quality or packaging?

Dry ice is food‑safe when handled correctly, but it can make cardboard brittle. Wrap the payload and keep packs from direct carton contact.

Q5: How do I dispose of leftover dry ice safely?

Let it sublimate in a well‑ventilated area away from children and pets. Never put it in a sink, drain, or sealed container.

Summary and recommendations

Key takeaways: Use dry ice wrap dry ice packs when the product must stay frozen. Shrink void space, top‑load CO₂, and vent the lid. Size CO₂ with the simple liters‑based rule and add 10–20% buffer for delays. Label UN 1845, record net kilograms, and train your team on safe handling.

Next steps: Pick one challenging route. Run a data‑logger test with your current recipe, then with dry ice wrap dry ice packs following the SOP here. Compare hold time and claims. If you ship weekly, standardize kit sizes by lane and season. Need a faster path? Use the decision tool below and contact our team for a tailored recipe.

Interactive elements for engagement

Quick decision tool: is dry ice right for this shipment?

-

Product target: Must it stay ≤ −10 °C?

-

Yes → Use dry ice wrap dry ice packs.

-

No → Consider gel or PCM.

-

-

Route band: Is your route warm (20–30 °C) or hot (30–40 °C)?

-

Warm → Start at 1.2 kg per 10 L per 24 h.

-

Hot → Start at 1.6 kg per 10 L per 24 h.

-

-

Hold time: 24, 48, or 72 h?

-

Multiply your base by 1×, 2×, or 3× and add 15% buffer.

-

Self‑check: will my box survive July?

-

Box internal liters measured and recorded

-

Dry ice wrap dry ice packs recipe printed on a card

-

Vented lid confirmed and labeled

-

Net CO₂ weight in kg on the box

-

One data logger inside per 20 boxes (rotating)

About Tempk

Tempk builds cold‑chain packaging and planning tools for brands that ship frozen and chilled products. We focus on practical SOPs and simple sizing rules that teams can apply under pressure. Our kits pair insulation, dry ice wrap dry ice packs, and easy labeling. You get repeatable results and fewer warm deliveries.

Call to action: Want a lane‑specific recipe? Share your box liters, route band, and target hold time. We’ll return a right‑sized dry ice wrap dry ice packs plan you can test this week.