Quarantine Dry Ice Packs: How to Size, Pack, and Comply in 2025

Quarantine dry ice packs help you protect temperature‑sensitive goods during customs holds, QA quarantine, or controlled storage. In this 2025 guide, you’ll learn when to choose dry ice over gel, how to size dry ice for 24–120 hours, and how to label, ventilate, and validate packaging to stay compliant and cost‑effective. You’ll also see practical checklists, a quick calculator, and trends that matter this year.

-

Pick the right quarantine dry ice packs for the lane and hold time

-

Use a simple formula to compute dry ice mass for 24–120 hours

-

Label and document shipments that contain quarantine dry ice packs

-

Compare gel packs vs. dry ice for quarantine conditions

-

Validate packaging and monitoring for audit‑ready records

-

Track 2025 trends that change how you deploy quarantine dry ice packs

What are quarantine dry ice packs and when should you use them?

Answer in brief: Quarantine dry ice packs are dry‑ice based refrigerants used to maintain deep‑cold conditions (around −78.5 °C) during inspection delays, customs holds, or QA release. Use them when product needs sub‑zero protection beyond gel packs and when quarantine time is uncertain or extended.

Explanation: In quarantine scenarios, you don’t control the clock. Dry ice sublimates to CO₂ gas and keeps the payload far below freezing for longer than gel packs. That buffer helps you ride out unpredictable holds. Choose quarantine dry ice packs for biologics, advanced therapies, and frozen foods that cannot tolerate thawing. In contrast, use gel when the set point is 2–8 °C or 15–25 °C and quarantine windows are tight and predictable.

Quarantine cold chain vs. routine shipping: what’s different?

Key point: Quarantine adds uncertainty, so your packout must tolerate longer dwell times, multiple handoffs, and ventilation constraints. Build that resilience into quarantine dry ice packs planning.

| Factor | Routine Shipping | Quarantine Shipping | What it means for you |

|---|---|---|---|

| Time certainty | Planned transit | Unplanned holds | Add 25–60% buffer dry ice |

| Handling | Single SOP | Mixed processes | Clear “open only in vented area” note |

| Docs | Standard labels | Extra status tags | Add quarantine identifier on outer box |

| Monitoring | Single logger | Redundant loggers | Place at core and near wall |

| Escalation | Fixed contacts | Multi‑agency | Include 24/7 contact on carton panel |

Practical tips for early wins

-

Quarantine location: Ask the receiver where holds occur. Plan ventilation there.

-

Access path: Design packouts so staff can add quarantine dry ice packs without exposing the payload.

-

Status control: Use bright quarantine decals and a checklist sleeve on the outer wall.

Real‑world case: A cell‑therapy site facing 36‑hour customs holds added 30% more quarantine dry ice packs and a vented over‑carton. Release rates improved and excursions dropped to zero in the next five lots.

How do you size quarantine dry ice packs for 24–120 hours?

Answer in brief: Estimate heat load, add safety for quarantine uncertainty, then convert to dry ice mass using a simple rule of thumb. For many insulated shippers, plan 0.7–1.0 kg per 24 hours per 6–8 L of internal space, then adjust for insulation quality and ambient extremes.

Explanation: Heat intrusion depends on insulation (EPS, EPP, VIP), box geometry, and ambient swing. Quarantine adds time variance, so increase the buffer. Keep quarantine dry ice packs off the product using trays or “donut” layouts that let CO₂ vent upward.

A rule‑of‑thumb calculator for dry ice mass

Use this starter formula to plan quarantine dry ice packs:

What to do next: Round up to the nearest 0.5 kg. If ambient exceeds 30 °C or the route is highly variable, add another 10–20%. Use test boxes to validate for your product.

| Scenario | Payload Volume | Hold Time | Insulation | Starting Dry Ice | Why it matters |

|---|---|---|---|---|---|

| Entry‑level EPS | 10 L | 48 h | EPS | ~1.2–1.6 kg | Add 30% for quarantine variability |

| EPP mid‑tier | 15 L | 72 h | EPP | ~2.0–2.6 kg | Better R‑value lowers mass |

| VIP hybrid | 20 L | 96 h | VIP+EPP | ~2.6–3.4 kg | Efficient wall reduces sublimation |

Tips to reduce mass without risking excursions

-

Pre‑condition the payload to target temperature before adding quarantine dry ice packs.

-

Use divider boards so dry ice never contacts vials or cartons.

-

Keep void space minimal. Air volume increases heat load.

-

Place quarantine dry ice packs above and around the payload, with a vent path to the top.

Compliance for quarantine dry ice packs: labels, documents, and safe handling

Answer in brief: Mark cartons with “UN 1845 Carbon dioxide, solid (Dry ice)” and the net dry ice weight in kilograms. Ensure vented packaging, add operator variations if flying, and include instructions that quarantine dry ice packs must be handled in a well‑ventilated area.

Explanation: For air transport, dry ice is a Class 9 dangerous good (UN 1845). When used only as a refrigerant for non‑dangerous goods, a full dangerous goods declaration is often not required, but the air waybill must show dry ice and the net weight per package. Many carriers also require a phone number and special handling codes. For passengers, the common limit is 2.5 kg in baggage with vented packaging and approval from the operator.

Minimum marks, labels, and documents to prepare

-

Proper shipping name and UN number: UN 1845, Dry ice.

-

Net weight of dry ice (e.g., “Dry ice 6.0 kg”).

-

Class 9 hazard label and handling note for quarantine dry ice packs.

-

Air waybill entry for dry ice with per‑package weight.

-

SDS available to handlers; do not seal the package airtight.

| Compliance Element | What to include | Where to place | What it means for you |

|---|---|---|---|

| UN marking | UN 1845, Dry ice | Outer carton panel | Meets air rules and speeds acceptance |

| Net weight | Total kg of dry ice | Near the UN marking | Enables safe stowage and audit |

| Vent path | Not airtight; vent holes | Lid/over‑carton | Reduces CO₂ buildup risk |

| Quarantine ID | “Quarantine Hold” sticker | Top and side | Clear status on arrival |

| 24/7 contact | Phone number/email | Main label cluster | Faster problem resolution |

Real‑world case: A biologics shipper added UN 1845 marks and a bold quarantine tag to the master carton. Customs cleared faster because handlers knew exactly what the quarantine dry ice packs needed for safe storage.

Packaging design: building quarantine dry ice packs that breathe

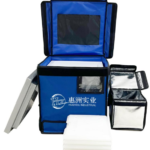

Answer in brief: Use an insulated shipper with controlled venting, keep quarantine dry ice packs separated from product, and arrange ice on top and sides to let CO₂ escape upward. Add an over‑carton with cutouts if local rules require visible venting.

Explanation: Dry ice sublimates to CO₂ gas that displaces oxygen in confined spaces. Your design must never be airtight. Layer trays or mesh racks above the payload to keep cartons dry and prevent freeze damage. Use foam spacers to create a gas chimney.

Gel packs as a quarantine backup: when to combine

Sometimes you want a hybrid packout: quarantine dry ice packs for deep‑cold, plus gel in a separate sleeve to buffer the payload if staff must open the shipper. This “fail‑soft” design gives you time to re‑charge with dry ice without shocking the product.

| Insulation Type | R‑Value (relative) | Weight | Impact on Dry Ice Mass | For you |

|---|---|---|---|---|

| EPS | Low | Light | Highest mass | Low cost, short holds |

| EPP | Medium | Medium | Medium mass | Good balance for quarantine |

| VIP hybrid | High | Medium | Lowest mass | Best for 72–120 h holds |

Do‑this‑now build tips

-

Add a rigid quarantine dry ice packs tray with drain slots.

-

Print “Open in Ventilated Area Only” on the inner lid.

-

Use foil liners to reduce radiant heat near the lid.

-

Add a re‑icing window (removable plug) on long quarantine lanes.

Monitoring and release: proving the chain of custody

Answer in brief: Pair quarantine dry ice packs with at least two temperature loggers—one at the core, one near the wall—and record re‑icing events. Define acceptance criteria before shipping so quarantine teams know when to release.

Explanation: In quarantine, proof matters as much as performance. Set clear start/stop timestamps, place serial numbers on the carton label, and synchronize logger clocks. Define who can re‑ice and what to record: time, mass added, ambient conditions, and initials.

Quarantine documentation set

-

Packout diagram showing quarantine dry ice packs locations

-

Pre‑shipment checklist with ice mass and logger IDs

-

Re‑icing log sheet (time, mass, person, reason)

-

Final report with time‑temperature curve and pass/fail decision

Real‑world case: A vaccine distributor added a second logger near the lid and a re‑icing log. After a 60‑hour quarantine, auditors accepted the run in minutes because the quarantine dry ice packs records were complete.

Common mistakes and how to fix them with quarantine dry ice packs

-

Airtight boxes: Dry ice inside sealed containers can cause pressure buildup. Fix with vent holes or vented lids.

-

Ice touching product: Direct contact can crack vials. Fix with trays and corrugated sleeves.

-

Under‑estimating time: Quarantine is unpredictable. Fix by adding a 30–60% buffer to quarantine dry ice packs mass.

-

Single logger: One sensor can hide edge warming. Fix with two loggers and a CO₂ hazard note.

-

No re‑icing plan: Staff guesswork leads to variability. Fix with a standard “add X kg every Y hours” chart.

When are quarantine dry ice packs better than gel, and when not?

Answer in brief: Choose quarantine dry ice packs for frozen and deep‑frozen products, or when holds exceed 24–48 hours. Choose gel packs for 2–8 °C or CRT lanes and short, predictable quarantines.

Explanation: Gel caps set at +5 °C or +20 °C are ideal for last‑mile holds at controlled temperatures. They are easier to handle and not regulated as dangerous goods. But when you must keep the product far below freezing during uncertain quarantine, quarantine dry ice packs provide stronger thermal headroom.

Quick decision guide

-

Target temperature: If ≤ −20 °C, prefer quarantine dry ice packs.

-

Hold time: If > 24 h with uncertainty, prefer dry ice.

-

Lane complexity: If air transport + customs, assume delays and choose dry ice.

-

Product sensitivity: If freeze shock risk, use trays and staged re‑icing or hybrid with gel.

A hands‑on checklist to reduce risk today

-

Confirm ambient: Ask for quarantine room temperature range before shipping.

-

Document venting: Add a “vented packaging” statement near the UN 1845 mark.

-

Standardize mass: Pre‑bag quarantine dry ice packs in 1 kg increments for accuracy.

-

Train re‑icing: Teach staff to open from the short side and keep the lid on a few centimeters.

-

Post‑event review: After every quarantine, update the plan with time and mass used.

A simple self‑assessment quiz (5 quick checks)

-

Do you state net quarantine dry ice packs weight (kg) on the label?

-

Can staff re‑ice without touching the product?

-

Do you have two loggers and synchronized clocks?

-

Is the package vented and clearly marked as vented?

-

Is there a phone number on the case for after‑hours quarantine?

Score yourself: 4–5 “Yes” = audit‑ready. 2–3 “Yes” = improve packout and SOPs. 0–1 “Yes” = redesign before next shipment.

2025 trends shaping quarantine dry ice packs

Trend overview: In 2025, extended‑duration shippers and hybrid solutions are mainstream. VIP‑lined cartons and reflective liners reduce dry ice mass. CO₂‑aware safety practices are becoming part of facility SOPs. Battery‑free data loggers with QR retrieval speed quarantine release.

Highlights at a glance

-

VIP mini‑kits: Lower mass requirements for quarantine dry ice packs by improving wall efficiency.

-

Hybrid buffering: Gel sleeves added inside dry‑ice shippers to cushion product during lid‑open events.

-

Digital release: QR‑based loggers let quarantine teams download data without cable hassles.

Market insight: More lanes include re‑icing stations near inspection areas, and shippers add over‑cartons with visual vents. Teams standardize ice additions in 1 kg bags to cut variability. Packaging libraries add pre‑validated 72–120 hour designs for accelerated rollout.

Frequently Asked Questions

Q1: How much dry ice do I need for a 72‑hour quarantine hold?

Start with the rule of thumb in this guide, then add 30–60% depending on ambient and uncertainty. Always validate the mass with a lane test before go‑live.

Q2: Can I put quarantine dry ice packs directly on cartons?

Avoid direct contact. Use trays, corrugate, or mesh to create a standoff and prevent freeze damage.

Q3: Do I need a dangerous goods declaration for quarantine dry ice packs?

Often not if dry ice is only a refrigerant for non‑dangerous goods, but you must mark UN 1845, show net weight, and follow operator rules.

Q4: What is the passenger baggage limit for dry ice?

Typically up to 2.5 kg with operator approval and vented packaging. For cargo, follow the carrier’s variations and packaging instruction requirements.

Q5: What if quarantine lasts longer than planned?

Train staff to re‑ice with pre‑bagged amounts and log the time, mass, and initials. Keep spare quarantine dry ice packs on site.

Q6: How do I prove compliance after release?

Provide the packout diagram, ice mass records, and logger data with a simple pass/fail summary tied to acceptance criteria.

Summary and recommendations

Key takeaways: Quarantine dry ice packs protect high‑risk products when holds are long or uncertain. Size mass using a clear rule of thumb, add a quarantine buffer, and design vented packouts with separation from the payload. Label UN 1845, list net weight, and monitor with two loggers to enable fast, audit‑ready release.

Next steps: Map your quarantine points, pick a shipper class (EPS, EPP, VIP), and pilot the packout for 72–120 hours. Standardize re‑icing in 1 kg increments, pre‑print labels, and train teams for vented handling. If you need help, run one lane test, then scale the validated design across products.

Internal link ideas (suggested, non‑clickable)

-

Cold chain packaging validation guide — /packaging/validation

-

Dry ice handling and CO₂ safety checklist — /safety/dry‑ice

-

Gel packs vs. dry ice: decision matrix — /coolants/selection

-

Temperature logger placement best practices — /monitoring/placement

-

VIP shipper buy‑vs‑build analysis — /packaging/vip‑strategy

Recommended schema markup

Use these types: Article, FAQPage, HowTo.

About Tempk

Tempk helps organizations plan, validate, and monitor cold chain packaging—especially when quarantine holds are part of the route. We provide packout design templates, data‑driven sizing tools for quarantine dry ice packs, and easy reporting that turns logger data into audit‑ready summaries. Our customers cut excursions and reduce coolant costs with standardized, validated designs.

Call to action: Talk to Tempk about your quarantine lane. Share your lane map and current packout, and receive a tailored quarantine dry ice packs plan within one project cycle.