How Do Cold Chain Medicines Stay Effective in 2025?

Keeping life saving medicines stable requires more than refrigeration—it demands a robust cold chain system. Cold chain medicines must travel from factories to hospitals within specific temperature ranges, often between 2 °C and 8 °C, or down to −150 °C for advanced therapies. Without these controls, delicate molecules degrade and vaccines lose potency, contributing to an estimated fifty percent vaccine wastage. In 2025 the global healthcare cold chain is worth billions of dollars and regulates temperatures from 2 °C to 8 °C for standard drugs and –90 °C to –60 °C for ultra cold biologics. This article, updated in November 2025, guides you through critical storage ranges, compliance strategies and emerging innovations to keep your medicines safe.

Why are cold chain medicines critical for patient safety? Find out how 50 % vaccine wastage and fragile biologics make temperature control essential.

What temperature ranges apply to different medicines? Explore guidelines for vaccines, insulin, biologics and cell gene therapies.

How can you maintain cold chain integrity day to day? Learn best practices for packaging, monitoring and regulatory compliance.

Which regulations govern pharmaceutical cold chains? Understand Good Distribution Practice (GDP), WHO standards and FDA requirements.

What trends are shaping cold chain medicine logistics in 2025? Discover how IoT sensors, AI, blockchain and multi temperature zones improve safety and efficiency.

Why are cold chain medicines critical for patient safety?

Cold chain medicines are crucial because they preserve drug efficacy and prevent waste. Most vaccines and biologics must stay between 2 °C and 8 °C. Cutting edge therapies—such as mRNA vaccines or viral vectors—require temperatures as low as –60 °C. When products drift outside these ranges, active ingredients degrade quickly, leading to lost potency and public health risks. The World Health Organization estimates that up to 50 % of vaccines are wasted globally because of temperature excursions. In addition, biopharmaceutical companies invest billions in research and production, so a single temperature lapse can destroy an entire batch and jeopardise patient safety.

Extended explanation:

You might think a medicine is “cold enough” if it feels chilled, but the molecules in vaccines and biologics are surprisingly delicate. Glycoproteins, enzymes and living cells lose structure when overheated, while freezing can cause crystals that denature proteins. According to a 2024 report on healthcare cold chains, most vaccines must remain within 2 °C–8 °C throughout distribution. Meanwhile, mRNA vaccines such as Pfizer BioNTech’s require –60 °C to –80 °C and Moderna’s vaccine requires –20 °C. More than 85 % of biologics—including monoclonal antibodies, recombinant proteins and ADCs—depend on cold chain management. Without these controls, molecules degrade, efficacy plummets and therapies become unsafe.

Temperature ranges for different medicine categories

Detailed information:

Modern pharmaceuticals span a spectrum of temperature requirements. Vaccines like DTaP, influenza and HPV typically require 2 °C–8 °C storage, while live attenuated vaccines may demand –15 °C to –50 °C. Insulin and other hormonal medications must remain at 2 °C–8 °C, though certain formulations can be kept at room temperature after opening. Biologics and biosimilars—monoclonal antibodies, recombinant proteins and ADCs—are highly temperature sensitive and largely require refrigerated conditions (2 °C–8 °C). Cell and gene therapies, including CAR T products, require cryogenic storage at −150 °C or lower in liquid nitrogen vapour. Peptides and proteins such as GLP 1 agonists for diabetes are also refrigerated.

| Category | Typical Temperature | Examples | Meaning for you |

| Vaccines | 2 °C–8 °C; some live attenuated vaccines need –15 °C to –50 °C | DTaP, influenza, hepatitis, measles | Use dedicated vaccine refrigerators and avoid overcrowding to keep doses potent. |

| Insulin & hormonal drugs | 2 °C–8 °C; limited room temperature storage after opening | Insulin, growth hormones, fertility drugs | Keep supply chilled during travel with portable coolers; follow manufacturer guidelines for opened vials. |

| Biologics & biosimilars | 2 °C–8 °C; some require –20 °C to –80 °C | Monoclonal antibodies, recombinant proteins, ADCs | Ensure continuous monitoring using IoT data loggers; small fluctuations can degrade these large molecules. |

| Cell & gene therapies | –60 °C to –150 °C | CAR T cells, AAV gene therapies, regenerative tissues | Use cryogenic shippers with liquid nitrogen vapour; maintain chain of custody from factory to clinic. |

| Peptides & proteins | 2 °C–8 °C | GLP 1 agonists, insulin analogues | Provide adequate insulation and phase change materials to prevent freezing during shipment. |

Practical tips and advice for users

During long haul transport: Use validated insulated containers with gel packs and real time temperature monitoring. For shipments crossing hot climates, choose active cooling systems that can maintain sub zero temperatures.

For home storage: Always place your medicines in the centre of a pharmaceutical grade refrigerator and avoid the door or vegetable bins; these areas fluctuate in temperature. Do not store vaccines alongside food or employee lunches.

When traveling: Carry a portable cooler or insulated bag with cold packs to keep insulin and other medicines within 2 °C–8 °C. Monitor temperature using compact data loggers and avoid leaving medications in a hot car.

Real case: In 2020 a large metropolitan health authority discovered thousands of COVID 19 vaccine doses spoiled when a freezer malfunction went unnoticed. Similar incidents spurred adoption of IoT temperature loggers that provide real time alerts, preventing losses and ensuring patients received potent vaccines.

How do we maintain cold chain integrity day to day?

Maintaining the cold chain requires proper equipment, trained staff and comprehensive monitoring. Pharmaceutical grade refrigerators and freezers offer uniform temperature control, alarms and data logging capabilities. Household refrigerators are not suitable; the freezer compartment can accidentally freeze vaccines. Staff should check and record temperatures at least twice daily, calibrate devices regularly and have backup power supplies and contingency plans.

Expanded details:

Effective cold chain management starts with temperature mapping. Mapping identifies hot and cold spots in storage units and ensures thermostats are accurate. Once mapping is complete, validated packaging—such as insulated shippers, phase change materials, gel packs and active containers—keeps products within range during transit. Data loggers and IoT sensors provide continuous visibility, allowing staff to intervene before a temperature excursion becomes a problem. Training is equally important. All personnel handling medicines must understand correct loading, how to respond to alarms and the importance of proper documentation.

Regulations and standards: GDP, GMP and WHO guidelines

Compliance with regulations is non negotiable in 2025. Good Distribution Practice (GDP) is an international standard that ensures medicines are stored and distributed under the right conditions, remain fully traceable and are protected from contamination, tampering and temperature fluctuations. Being GDP certified requires audited operations with strict safety procedures, documentation, temperature control, quality management and staff training.

In addition to GDP, national agencies such as the FDA and EMA enforce Good Manufacturing Practice (GMP) and require that temperature control continues from production to final dispensing. The WHO’s vaccine storage toolkit recommends storing vaccines between 2 °C and 8 °C, with some live vaccines requiring –15 °C to –50 °C. Facilities must check temperatures twice daily and keep detailed logs. Failure to comply can lead to penalties, product recalls and reputational damage.

| Regulatory framework | Focus | What it means for you |

| GDP (Good Distribution Practice) | Ensures medicines are stored, transported and documented under correct conditions | Partner only with GDP certified logistics providers; maintain full traceability and quality management systems. |

| WHO Vaccine Storage Guidelines | Specifies that most vaccines need 2 °C–8 °C and that live vaccines may require –15 °C to –50 °C | Use purpose built vaccine refrigerators; avoid household units; monitor temperatures twice daily. |

| FDA/EMA GMP | Governs manufacturing and distribution quality; demands validated equipment and processes | Conduct regular audits and validation studies for storage, shipping and packaging; maintain documentation and training records. |

| IATA CEIV Pharma | Certifies air cargo providers for handling temperature sensitive cargo | Choose airlines with CEIV Pharma certification to minimise risks during air transport. |

Practical compliance tips and solutions

Develop SOPs: Create standard operating procedures for every step—receiving, storage, transport, monitoring and emergency responses. Update them regularly to reflect new guidelines.

Implement continuous monitoring: Use IoT temperature sensors and data loggers that alert staff via SMS or email when a temperature drifts out of range. Integrate these systems into your quality management software for audit trails.

Train and retrain: Conduct regular training for all staff involved in handling medicines, emphasising proper storage (centre of shelf, avoid overcrowding), reading sensors and responding to alarms.

Plan contingencies: Keep backup power supplies, portable coolers and alternative storage sites to mitigate power failures or equipment breakdowns. Perform emergency drills quarterly to test readiness.

Actual case: A community health clinic upgraded to GDP compliant refrigerators and adopted digital logs. During a blackout, their backup generator kicked in automatically. Staff transferred vaccines to portable coolers per SOP and recorded the excursion. The clinic retained compliance and avoided waste.

Which trends and innovations shape cold chain medicine logistics?

2025 trends show a move toward smarter, multi temperature and sustainable cold chain systems. Traditional cold chain strategies centred on maintaining 2 °C–8 °C refrigeration, but new biologics and gene therapies demand –20 °C, –40 °C and –80 °C conditions. Over 40 % of newly approved drugs in 2024 were biologics requiring cold or ultra cold storage. To meet these needs, logistics providers implement modular ultra cold freezers, IoT connected storage units, automated handling systems and smart packaging. Multi temperature zones within warehouses—ranging from 2 °C–8 °C to cryogenic (liquid nitrogen)—allow flexible scaling.

Expanded explanation:

The cold chain is evolving beyond simple refrigeration. High throughput biologics pipelines, personalised medicine and e commerce home delivery are driving innovation. Analysts project the global healthcare cold chain logistics market reached about USD 18 billion in 2024 and could exceed USD 23 billion by 2033. Another industry report estimates the broader healthcare cold chain—including services and equipment—may surpass USD 65 billion by 2025 and reach USD 154.7 billion by 2035. The pharmaceutical cold chain logistics market alone could grow to around $21.3 billion by 2025 at a 7.5 % CAGR, reflecting increased reliance on temperature controlled logistics. Meanwhile, nearly 30 % of temperature controlled shipments experience delays, highlighting the need for predictive analytics and contingency planning.

Emerging therapies and cryogenic storage

Advanced therapies are the biggest drivers of new cold chain requirements. The global cell and gene therapy CDMO market was valued at USD 6.31 billion in 2024 and is predicted to reach USD 74.03 billion by 2034—a staggering 27.92 % CAGR. CAR T therapies for cancers must be stored at –150 °C or lower in liquid nitrogen vapour. Viral vector gene therapies also require ultra cold storage to keep viral particles viable. Biologics pipeline expansion means over half of late stage drug candidates are advanced biologics and specialty medicines, emphasising cryogenic logistics.

| Therapy type | Storage range | Notable details | What this means |

| mRNA vaccines | –60 °C to –80 °C | Pfizer BioNTech and similar vaccines; require ultra cold freezers | Invest in ultra low freezers and validated shipping containers; avoid re freezing after thawing. |

| Viral vector gene therapies | –60 °C to –150 °C | AAV, lentivirus gene therapies; maintain viral viability | Use cryogenic packaging and continuous temperature logging; ensure chain of custody for personalised doses. |

| CAR T and cell therapies | ≤ –150 °C | Living cells for cancer treatment; extremely sensitive | Employ liquid nitrogen vapour phase storage and ensure staff are trained in handling cryogenic dewars. |

| Peptide/protein drugs | 2 °C–8 °C | GLP 1 agonists (semaglutide); insulin analogues | Use insulated packaging with phase change materials; monitor for freezing. |

User oriented trends and best practices

IoT and real time monitoring: Smart sensors track temperature, humidity and location, sending alerts when deviations occur. These devices reduce unplanned downtime and save energy.

Artificial intelligence and predictive analytics: AI analyses historical data to predict delays and re route shipments. Predictive systems can cut unplanned downtime and generate energy savings.

Blockchain for traceability: Blockchain creates an immutable record of a medicine’s journey, ensuring authenticity and simplifying recalls.

Multi temperature and modular storage: Facilities now use modular freezer systems that can rapidly change temperature zones and scale capacity.

Sustainability: Demand for biodegradable packaging and energy efficient equipment is rising. Sustainable materials such as cotton mailers and eco friendly gel packs reduce environmental impact.

Example: In 2025 a pharmaceutical company adopted modular ultra cold storage to support its growing pipeline of mRNA vaccines. The facility implemented AI driven route optimisation and blockchain traceability, cutting shipment delays by 20 % and reducing wastage.

2025 latest developments and trends

Trend overview:

The landscape continues to evolve rapidly. In 2025 the cold chain medicine sector sees bigger biologics pipelines, more home delivery of drugs and increasing regulatory scrutiny. Multi temperature warehouses provide zones from 2 °C to –150 °C, ensuring flexibility. Drones and autonomous vehicles are being tested for last mile delivery. Hydrogen fuel cell powered trucks and solar assisted refrigeration reduce emissions. Strict GDP audits drive adoption of digital documentation systems and training. Companies invest in predictive maintenance for refrigeration equipment, lowering unplanned downtime.

Latest progress at a glance

Digital integration: More logistics providers integrate IoT sensors with central dashboards, giving you one screen visibility across the supply chain and compliance reports on demand.

Multi temperature hubs: Warehouses with zones of 2 °C–8 °C, –20 °C and –80 °C allow companies to scale new drug volumes without investing in separate facilities.

Sustainable packaging: Adoption of biodegradable liners and reusable pallets reduces waste and aligns with ESG goals.

Increased regulatory enforcement: Audits focus on real time temperature logs and chain of custody. GDP and GMP compliance is now a market requirement.

Growth of personalised medicine: As cell therapies move from trials to commercial use, cryogenic shipping networks expand, with dedicated cryo hubs in major markets.

Market insights:

The pharmaceutical cold chain logistics market is expanding quickly. Analysts estimate it will reach $21.3 billion by 2025. The broader healthcare cold chain—including services and equipment—may surpass $65 billion in 2025 and climb to $154.7 billion by 2035. Despite growth, nearly 30 % of temperature controlled shipments face delays, highlighting the need for predictive planning. Meanwhile, personalised therapies create strong demand for cryogenic logistics, with the cell and gene therapy CDMO market expected to grow from $6.31 billion in 2024 to $74.03 billion by 2034.

Frequently Asked Questions

What medicines need to stay between 2 °C and 8 °C? Most vaccines, insulin and many biologic drugs require refrigerated storage at 2 °C–8 °C. Check the package insert and avoid storing them in household refrigerators’ door compartments.

Can I use a regular fridge for vaccine storage? No. Household refrigerators often have inconsistent temperatures and freezer compartments that can accidentally freeze vaccines. Pharmaceutical grade refrigerators with alarms and uniform cooling are recommended.

How should I store insulin while traveling? Use an insulated travel case with ice packs to maintain 2 °C–8 °C. Keep insulin out of direct sunlight and monitor temperature with a small data logger.

Why is temperature monitoring important? Continuous monitoring alerts you to temperature excursions, allowing quick corrective actions. Without monitoring, you risk losing product potency and failing regulatory audits.

Do gene therapies require special storage? Yes. Gene and cell therapies often need –150 °C cryogenic storage. Only specialised cryogenic shippers and storage facilities can maintain such low temperatures.

Summary and recommendations

Key points: Cold chain medicines must stay within precise temperature ranges—2 °C–8 °C for most vaccines and biologics, and down to –150 °C for cell and gene therapies. Without rigorous controls, up to 50 % of vaccines may be wasted. Proper equipment, continuous monitoring and trained staff are non negotiable. Market growth and personalised medicine are driving innovations like IoT sensors, AI route optimisation and multi temperature hubs.

Actionable advice: 1) Evaluate your current cold chain against GDP and WHO guidelines. 2) Implement real time temperature monitoring and data logging. 3) Train staff on correct storage and emergency procedures. 4) Invest in modular, multi temperature equipment to future proof your operations. 5) Use our cold chain compliance self assessment tool to benchmark your readiness and identify gaps. Taking these steps will ensure your medicines stay potent and your patients stay safe.

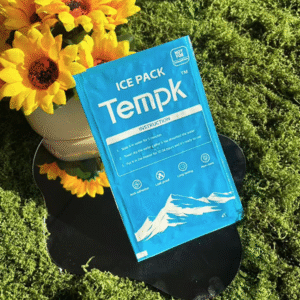

About Tempk

Tempk is a leading provider of sustainable cold chain packaging and monitoring solutions. We design insulated boxes, gel packs and modular freezers tailored for healthcare applications. Our R&D team pioneers technologies like smart packaging and renewable refrigerants, helping you maintain strict temperature ranges while reducing environmental impact. With decades of experience and GDP certified facilities, we partner with pharmaceutical and biotech companies worldwide to safeguard temperature sensitive products.

Next steps: Want to enhance your cold chain? Contact our experts for a personalised consultation or try our self assessment tool to evaluate your compliance today.