Cold Chain Fresh Seafood Guidelines Solutions?

If you ship, store, or sell seafood, cold chain fresh seafood guidelines solutions are how you protect texture, odor, and margin. Aim to keep chilled fish near melting-ice conditions (about 0–4°C / 32–39°F) and avoid warm exposure beyond common safety “time-out” rules. One weak handoff can trigger soft flesh, sour odor, and wet boxes. This guide gives you a repeatable SOP: temperature targets, leak control, fast checks, and monitoring you can run daily.

This guide answers:

-

How cold chain fresh seafood guidelines solutions reduce spoilage in last-mile delivery

-

The ideal temperature for fresh seafood transport you can train in one day

-

A simple rule for how long can fresh seafood stay above 40°F

-

The ice and drainage requirements for fish transport that stop “wet box” claims

-

A practical histamine control plan for tuna and mahi-mahi lanes

-

A 2025-ready monitoring checklist that helps you prove performance

Why do cold chain fresh seafood guidelines solutions fail in real operations?

Cold chain fresh seafood guidelines solutions fail when temperature, water, and handling are treated as “someone else’s problem.” Seafood is high moisture and high protein, so small drift becomes fast quality loss. Most failures are not mysterious. They repeat in the same three places: warm staging, meltwater contact, and rough handoffs.

In practice, think “clock + sponge.” Heat makes the clock run faster. Meltwater makes the sponge absorb off-odors and texture damage.

| Failure point | What happens | What you see | What it means for you |

|---|---|---|---|

| Temperature drift | Faster spoilage and safety risk | Soft texture, sour odor | Refunds and trust loss |

| Meltwater leakage | Labels and cartons fail | Wet boxes, stains | Carrier claims and reships |

| Cross-contamination | Odors and risks transfer | Mixed odors, messy exterior | Higher compliance and brand risk |

Practical tips you can apply today

-

Dock-to-box time: treat every warm minute as “quality debt.”

-

Design for meltwater: assume ice melts and build barriers and drainage.

-

Assign ownership: one person owns temp checks; one owns pack-out checks.

Practical example: A shipper cut “wet box” photos by adding a secondary leak barrier and upgrading the outer carton strength.

What temperature targets fit cold chain fresh seafood guidelines solutions?

Cold chain fresh seafood guidelines solutions work best when you pick one target range and design everything to hold it. For chilled seafood, many operations train “near ice” targets to slow spoilage without freezing. For frozen seafood, the goal is “stay frozen” through every handoff, with minimal thaw–refreeze cycling.

If your team argues about targets, simplify the message: chilled stays near ice, frozen stays frozen, live stays alive and not overheated.

Ideal temperature for fresh seafood transport (lane-ready targets)

| Product type | Simple target | What usually holds it | What it means for you |

|---|---|---|---|

| Fresh fish (iced/chilled) | Near 0°C / 32°F | Ice contact + drainage | Longer shelf life, firmer texture |

| Chilled seafood (retail cold) | ≤4°C / 40°F | Refrigeration + fast handling | Safer buffer when ice is limited |

| Frozen seafood | ≤–18°C / 0°F | Freezer/reefer + stable loading | Prevents quality loss from partial thaw |

| Live shellfish | Cool, not frozen | Cool air + humidity control | Higher survival and fewer dead losses |

Practical tips you can apply today

-

Start cold: packing warm seafood into a cold shipper is a losing fight.

-

Avoid direct freezing contact: separate product from aggressive cold sources.

-

Standardize staging: pre-chill product and packaging in the same zone.

Practical example: A distributor improved arrival quality by reducing “warm staging” time, without changing materials.

How do cold chain fresh seafood guidelines solutions control warm time above 40°F?

Cold chain fresh seafood guidelines solutions control time as tightly as temperature, because warm minutes stack up fast. Many food-safety training rules use a practical threshold around 40°F / 4°C for refrigeration and warn against extended time in the “danger zone.” Your SOP should translate that into a simple exposure budget your team can follow under pressure.

Ten minutes here plus fifteen minutes there becomes lost shelf life. The fix is designing fewer waiting steps and tighter handoffs.

A time–temperature exposure budget you can audit

| Step | Warm-time limit (example) | How to measure | Meaning for you |

|---|---|---|---|

| Receiving | 10–20 minutes | Door-open timestamps | Fewer warm spikes |

| Processing/packing | 30–60 minutes | Line start/end logs | More shelf life left |

| Loading | 15–30 minutes | Dock scan times | Fewer “mystery warms” |

| Last mile | Minimize stops | Route + delivery events | Fewer complaints |

Practical tips you can apply today

-

Start a visible timer when seafood leaves cold storage.

-

Remove double-handling: each transfer adds minutes and heat.

-

Write exception rules: if the budget is exceeded, hold or escalate fast.

Practical example: A processor gained freshness by deleting one staging step and enforcing a 30-minute max at the pack table.

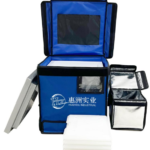

Which packaging layers make cold chain fresh seafood guidelines solutions reliable?

Cold chain fresh seafood guidelines solutions work as a layered system, not a single material choice. If you upgrade insulation but ignore leaks, you still fail. If you add absorbent pads but ignore crush risk, you still fail.

A reliable seafood pack-out typically uses five layers:

-

Primary containment: food-grade bag or sealed tray

-

Leak barrier: secondary liner or sealed overbag

-

Cold source: ice, gel, or hybrid approach

-

Insulation: foam shipper or insulated liner

-

Outer protection: strong carton + clear labels

Leak control that actually reduces “wet box” claims

| Leak method | Strength | Weakness | What it means for you |

|---|---|---|---|

| Double bagging | Simple and reliable | Adds labor | Fewer wet-box failures |

| Sealed liner | Strong barrier | Needs consistent sealing | Better scale consistency |

| Absorbent pads | Reduces free liquid | Can saturate | Use as backup, not the only fix |

Practical tips you can apply today

-

Make the secondary barrier mandatory for iced seafood.

-

Add a divider layer between cold source and product.

-

Right-size the box to reduce movement and crushing.

Practical example: A brand reduced crushed fillets by switching to snug-fit dividers, without changing insulation.

Ice vs gel vs hybrid: which cold chain fresh seafood guidelines solutions should you use?

Cold chain fresh seafood guidelines solutions often succeed with ice, but only when drainage and containment are designed as non-negotiable. Gel packs reduce leak risk, but sizing mistakes cause warm arrivals. Hybrid systems can stabilize both temperature and cleanliness, especially on 2–3 day lanes.

Use one decision tool, then standardize one recipe per SKU. Consistency beats improvisation.

A 60-second pack-out decision tool (interactive)

Answer these quickly:

-

Transit time: 0–24h / 24–48h / 48–72h

-

Handoff risk: low / medium / high

-

Leak tolerance: low (premium retail) / medium / high

-

Product form: whole / fillet / shellfish / mixed box

Quick match:

-

48–72h OR high handoff risk: Hybrid + stronger insulation

-

24–48h with low leak tolerance: Gel-forward + secondary barrier

-

0–24h: Ice-forward + strong leak design (fast and simple)

| Pack-out type | Best for | Watch-outs | Meaning for you |

|---|---|---|---|

| Ice-forward | Same-day, overnight | Meltwater | Strong “freshness feel” |

| Gel-forward | Premium unboxing | Under-sizing | Cleaner delivery |

| Hybrid | 2–3 day routes | More steps | Highest stability |

Practical tips you can apply today

-

Don’t under-pack cold source: small savings become big losses.

-

Don’t over-pack: too much can crush product or overcool edges.

-

Create SKU cards: one recipe per box size and species group.

Practical example: A shipper cut errors by standardizing two recipes: “Fillet Box” and “Shellfish Box.”

How should your receiving checklist support cold chain fresh seafood guidelines solutions?

Cold chain fresh seafood guidelines solutions win or lose at receiving, because that’s where problems enter and good product gets damaged by slow checks. You need a checklist that takes minutes. You also need a clear accept/hold/reject rule, so staff do not guess.

The 2-minute seafood receiving checklist (printable)

-

Temperature: quick probe in the coldest spot (between packs).

-

Ice condition: solid ice coverage for chilled fish lanes.

-

Meltwater: no soaking; drainage is present and working.

-

Packaging integrity: no tears, leaks, or crushed corners.

-

Paperwork + IDs: lot labels match and are readable.

Live shellfish receiving temperature checklist

Live shellfish often need checks that are fast and consistent:

-

Product temperature: ≤10°C / 50°F (common operational limit)

-

Vehicle/container air: ≤7.2°C / 45°F (common operational limit)

| Receiving item | What you check | Pass signal | Meaning for you |

|---|---|---|---|

| Chilled fish | Core temp + ice coverage | Near ice conditions | Better shelf life |

| Frozen seafood | Frozen solid | No soft spots | Protects texture |

| Live shellfish | Product + air temp | Within limits | Higher survival |

Practical tips you can apply today

-

Pre-stage tools: probes, gloves, labels ready before arrival.

-

Use “hold and review” stickers for borderline lots.

-

Reject wet-bottom cartons if leaks are your top complaint.

Practical example: A retailer reduced waste by rejecting deliveries with poor ice coverage and enforcing a fast temperature check.

What HACCP-style controls strengthen cold chain fresh seafood guidelines solutions?

Cold chain fresh seafood guidelines solutions become easier when your SOP follows HACCP-style logic: limits, monitoring, corrective actions, and records. If you operate as a seafood processor in some jurisdictions, written plans and records may be required. Even if you are not, the structure reduces disputes and prevents repeat failures.

Keep it plain: define what “good” looks like, measure it, and act fast when it’s not good.

Histamine control plan for tuna and mahi-mahi lanes (simple version)

Histamine-risk species can look fine but become unsafe after temperature abuse. The best control is strict time–temperature discipline.

| Control point | What you monitor | Simple signal | Meaning for you |

|---|---|---|---|

| Receiving | Internal temp + condition | Meets your cold target | Fewer high-risk lots |

| Processing | Time out of refrigeration | Exceeds warm-time budget | Prevents invisible risk |

| Storage/transport | Cooler stability | Drift beyond limit | Stops repeat failures |

Practical tips you can apply today

-

Prioritize high-risk lots first at receiving and processing.

-

Pre-write corrective actions: “If X, then do Y within Z minutes.”

-

Sign records weekly: discipline improves when leaders sign.

Practical example: A distributor reduced exposure by scheduling tuna receiving in the first delivery slot.

How do you monitor and prove cold chain fresh seafood guidelines solutions work?

Cold chain fresh seafood guidelines solutions improve faster when you can prove what happened, not just guess. Monitoring builds customer confidence and makes complaints solvable. Start small: measure what drives decisions, then expand.

Minimum viable monitoring:

-

Product temperature spot checks at pack-out

-

Time stamps (pick, pack, handoff)

-

Packaging version code (so you can compare outcomes)

-

Complaint reason codes (odor, leak, warm, damage)

The Cold Chain Readiness Score (interactive self-test)

Add your points:

-

Transit time: same day (1) / next day (3) / 2+ days (5)

-

Ambient heat: low (1) / medium (3) / high (5)

-

Product type: frozen (1) / chilled fish (3) / live shellfish (5)

-

Delivery mode: reefer (1) / mixed (3) / non-reefer last mile (5)

-

Customer promise: bulk (1) / retail (3) / premium DTC (5)

Score guide:

-

5–10: basic controls + strict receiving checks

-

11–18: thicker insulation + logger on key lanes

-

19–25: lane-based pack-outs + real-time alerts on worst routes

| Monitoring item | Tool level | Frequency | Meaning for you |

|---|---|---|---|

| Pack-out temp check | Probe | Per batch | Early warning |

| Time stamps | Scan or manual | Every order | Root-cause clarity |

| Packaging version | Label code | Every order | Controlled testing |

Practical tips you can apply today

-

Fix your worst lane first: hottest route teaches you fastest.

-

Place sensors near product, not ice: ice can hide the truth.

-

Track door-open time: many spikes happen at loading.

Practical example: A shipper found the staging area was hotter than the truck, and solved excursions by changing flow.

2025 latest developments and trends

In 2025, cold chain fresh seafood guidelines solutions are shifting from “best effort” to “measurable control.” Customer expectations are higher, and photos of leaks or damage spread fast. The winners standardize pack-outs, validate by lane, and improve with weekly feedback loops.

Latest progress snapshot

-

Lane-based recipes: fewer variants, fewer errors, better consistency.

-

Cleaner pack-outs: drainage-first designs and stronger secondary barriers.

-

Smarter right-sizing: less empty space, less movement, fewer crushed items.

-

Superchilling pilots: some operators use controlled subzero ranges (e.g., around –0.5 to –2°C) on validated lanes.

-

Proof culture: more temperature logging to reduce disputes and speed corrective action.

Market reality: “cold, clean, documented” has become a competitive advantage, not just compliance.

Frequently asked questions

Q1: What is the ideal temperature for fresh seafood transport?

A practical target is chilled fish near melting-ice conditions, with fast handoffs and minimal warm staging. Use one lane target and train it clearly.

Q2: How long can fresh seafood stay above 40°F?

Use a simple rule: minimize time above 40°F, and set a warm-time budget for receiving, packing, and last mile. If you exceed it, hold and decide fast.

Q3: How do I reduce wet box complaints quickly?

Add a secondary leak barrier, enforce sealing consistency, and include absorbent backup. Design your SOP assuming meltwater will happen.

Q4: Ice or gel packs—what’s better for my lane?

Ice is strong for “near-ice” targets but needs drainage control. Gel is cleaner but must be sized correctly. Hybrid often wins for 2–3 day lanes.

Q5: What should I do differently for live shellfish?

Use quick receiving checks (product and air temperature), avoid soaking in meltwater, and keep conditions cool without freezing.

Q6: Do I need sensors to improve?

Not at first. Start with strict receiving checks, time stamps, and packaging version codes. Add loggers on your hottest lanes as you scale.

Summary and recommendations

Cold chain fresh seafood guidelines solutions work when you control three outcomes: stable cold, dry handling, and simple proof. Keep chilled seafood near ice targets, reduce warm staging with a time budget, and design packaging as a layered system. Use the 3 checks (cold, leak, shake) to prevent the most common failures. Review complaints weekly by lane, then update one recipe at a time.

CTA: If you share your transit window, seafood type (fillet, whole, shellfish, live), and delivery model (B2B or DTC), you can turn these cold chain fresh seafood guidelines solutions into three printable pack-out workcards: Light, Balanced, High Protection.

About Tempk

At Tempk, we support temperature-controlled packaging programs built for real logistics pressure. We help teams turn cold chain fresh seafood guidelines solutions into repeatable SOPs that reduce leaks, stabilize temperature, and improve unboxing cleanliness. We focus on lane-based pack-out design, practical monitoring, and measurable outcomes your team can maintain daily.

Next step: Request a lane review, and we’ll map a simple packaging + monitoring checklist your team can implement immediately.