Last updated: December 19, 2025

Cold chain seafood products succeed when you control temperature, hygiene, and traceability across every handoff. If you miss one step, seafood can arrive “on time” but still be rejected. Many chilled lanes work around 0–4°C (32–39°F), while many frozen lanes aim for ≤−18°C (0°F). The goal is simple: fewer warm swings, fewer wet cartons, and clearer proof at receiving.

This article will help you:

-

Define cold chain seafood products by category (chilled, frozen, live, value-added)

-

Turn seafood cold chain requirements into a repeatable 5-pillar system

-

Set practical cold chain seafood temperature requirements without confusing staff

-

Choose seafood packaging solutions that prevent leaks, crush, and heat spikes

-

Build seafood temperature monitoring that creates action, not noise

-

Train a receiving-friendly seafood QA checklist and exception playbook

-

Validate lanes using a seafood cold chain validation checklist you can run this month

What counts as cold chain seafood products in daily operations?

Cold chain seafood products are any seafood items where safety or quality depends on staying cold end-to-end. That includes products that spoil quickly, products that leak, and products where traceability must be flawless. If you ship seafood through multiple handoffs, you are operating a cold chain—even if you don’t call it that.

Think of cold chain seafood products like ice cream in a backpack. It can start perfect and still fail. The failure usually happens during the “in-between moments.”

Cold chain seafood products categories you should separate

| Category | Typical examples | What fails first | Your operational focus |

|---|---|---|---|

| Fresh / chilled | whole fish, fillets, cooked chilled seafood | odor, texture, drip | speed + temperature stability |

| Frozen | IQF shrimp, blocks, glazed fish | partial thaw, refreeze damage | stable frozen state |

| Live shellfish | oysters, clams, mussels | stress, mortality, label checks | viability + traceability discipline |

| Value-added | ready-to-cook, ready-to-eat seafood | hygiene + label errors | separation + strict handling |

Practical tips and suggestions

-

Don’t use one “universal” SOP for all cold chain seafood products.

-

Separate lanes by chilled vs frozen vs live first. Then optimize.

-

Train staff to recognize what “failure” looks like for each category.

Practical example: A team reduced mis-sorts by labeling staging racks as LIVE / CHILLED / FROZEN and enforcing simple routing rules.

Cold chain seafood products requirements: the 5 pillars you must control

Most cold chain seafood products requirements collapse into five pillars: temperature, hygiene, hazard control, traceability, and verification. You don’t need a perfect system. You need a repeatable system that prevents repeat mistakes.

If you control these pillars, you reduce rejections and claims. You also make audits easier.

The 5 pillars (plain language)

-

Time–temperature control: keep it cold and avoid swings

-

Hygiene control: prevent contamination during handling

-

Hazard control: focus on product-specific risks (HACCP thinking)

-

Traceability: keep lot identity attached and visible

-

Verification: keep records that prove what happened

HACCP explained: HACCP means Hazard Analysis and Critical Control Points. In simple terms, you identify where risk happens, then control those steps.

Requirements vs. real-world failure modes

| Requirement pillar | What “good” looks like | Common failure | What it means for you |

|---|---|---|---|

| Temperature | clear targets + short handoffs | warm staging and door-open time | shorter shelf life |

| Hygiene | sealed packs + clean tools | wet cartons and cross-contact | odor and safety risk |

| Hazard control | species-aware rules | “one rule fits all” | avoidable incidents |

| Traceability | lot stays with product | commingling and relabel errors | bigger recalls |

| Verification | quick, consistent records | “no evidence” disputes | weaker claim defense |

Practical tips and suggestions

-

Put your targets on wall charts and pack-out photos.

-

Treat cross-docking as high-risk by default.

-

Use one “golden rule” for teams: Keep it cold. Keep it sealed. Keep the lot identity.

Practical example: A distributor reduced disputes after making pack-out time and receiving time mandatory on every shipment.

What temperature requirements should cold chain seafood products follow?

Cold chain seafood temperature requirements must be easy to remember and easy to enforce. Complex temperature bands fail in busy shifts. Use one target per category, plus one action rule when you drift.

Many chilled programs use 0–4°C (32–39°F) as a working range. Many frozen programs use ≤−18°C (0°F) as a working target. Always align with your buyer specs and local rules.

Practical targets by cold chain seafood products category

| Category | Practical working target | Biggest risk | What you do if it drifts | What it means for you |

|---|---|---|---|---|

| Chilled seafood | 0–4°C | warming + drip | hold + QA check | fewer odor complaints |

| Frozen seafood | ≤−18°C | thaw/refreeze | inspect + assess excursion | better texture |

| Live shellfish | cool, stable (species-dependent) | stress/mortality | separate + inspect | less dead loss |

| Ready-to-eat seafood | tight control, shortest exposure | higher safety sensitivity | reject if uncertain | protects customers |

The biggest temperature mistake: cycling, not peaks

Many teams only look for the “maximum temperature.” That misses the real killer: temperature cycling.

A typical cycle looks like this:

-

warms during loading

-

cools again in transit

-

warms at receiving

-

cools again in storage

Cycling shortens shelf life and increases drip. It can also create inconsistent product within the same carton.

H3: The “Time-Out-of-Cold” rule for cold chain seafood products

Use a timer rule your team can follow without arguing:

-

Green: brief exposure during normal work

-

Yellow: longer exposure → hold and inspect

-

Red: sustained exposure → reject or rework per your food safety plan

| Zone | What triggers it | First action | Why it helps you |

|---|---|---|---|

| Green | short handling exposure | continue SOP | normal flow |

| Yellow | longer exposure | hold + evaluate | consistent decisions |

| Red | sustained exposure | reject/rework | avoids risky releases |

Practical tips and suggestions

-

Measure product-zone temperature when possible. Ambient air is misleading.

-

Set a staging limit in minutes, not “soon.”

-

Train the team to reduce door-open time during loading.

Practical example: A retailer cut “fishy smell” complaints after enforcing a simple yellow-zone hold rule.

Which hazards drive cold chain seafood products requirements?

Cold chain seafood products requirements exist because seafood has hazards that worsen when temperature rises or hygiene slips. You don’t need to scare your team with long lists. You need a few hazard “buckets” that guide your SOP choices.

Think of hazards like “spoilers” in a movie. Temperature and time give them the chance to show up.

Hazard buckets (operations-friendly)

| Hazard bucket | Where it hits hardest | What increases risk | Your control focus |

|---|---|---|---|

| Histamine risk | certain finfish species | warm time during handling | strict time/temperature discipline |

| Bacterial growth | chilled products | cycling and long staging | fast handoffs + cold stability |

| Parasite controls | raw-intended products | missed freezing treatment | product-specific rules |

| Natural toxins / chemicals | sourcing-dependent | poor records | traceability strength |

| Physical contamination | any product | sloppy handling | clean tools + sealed packs |

Practical tips and suggestions

-

Don’t treat all seafood as equal risk. Category rules reduce mistakes.

-

Build “raw-intended” handling as a special workflow, not a footnote.

-

Make traceability part of hazard control. It limits scope if something happens.

Practical example: Teams often reduce risk faster by improving handoffs than by adding more coolant.

Cold chain seafood products solutions: packaging that prevents leaks and heat spikes

The best seafood packaging solutions work as a system: insulation + containment + stability. If you only solve temperature, you still get leaks and crushed trays. If you only solve leaks, you still get warm product.

Use a small number of validated pack-outs. Too many options create confusion.

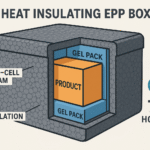

The 3-layer packaging model (simple, repeatable)

-

Insulation layer: slows outside heat

-

Containment layer: prevents leaks and isolates meltwater

-

Stability layer: stops movement and crush damage

Packaging options for cold chain seafood products (quick comparison)

| Packaging option | Best for | Strength | Weak spot | Your practical meaning |

|---|---|---|---|---|

| Insulated mailer + packs | short–medium DTC | simple and scalable | limited long heat | good starter |

| Rigid insulated box | medium–long lanes | better stability | higher volume cost | fewer swings |

| Reusable EPP box | multi-stop B2B | durable and stackable | needs cleaning SOP | strong ROI in loops |

| High-performance panels (VIP style) | premium/high risk | strong insulation | cost + handling | best for tough lanes |

| Secondary leak barrier | wet seafood | cleaner handling | adds a step | fewer rejections |

H3: The meltwater trap (why “iced fish” cartons fail)

Ice keeps seafood cold, but meltwater can:

-

weaken cartons

-

smudge labels

-

contaminate outer surfaces

-

create a bad unboxing experience

Rule: keep product separated from free water using liners, trays, absorbent layers, or sealed inner packs.

| Meltwater control | What it does | Common mistake | Your benefit |

|---|---|---|---|

| Sealed inner liner | blocks free water | relying on carton alone | cleaner receiving |

| Absorbent layer | manages small leaks | hiding major leaks | fewer messy reworks |

| Upright inserts | prevents slosh/crush | loose packs shifting | fewer burst packs |

| “Dry label zone” | keeps IDs readable | labels on wet corners | better traceability |

Practical tips and suggestions

-

Right-size the shipper to reduce headspace. Empty air warms fast.

-

Immobilize packs so they can’t rub, burst, or crush.

-

Keep coolant off direct contact with delicate product when possible.

Practical example: A chilled fillet program reduced “wet box” rejections after adding a sealed inner liner and a dedicated absorbent layer.

What solutions work best for chilled cold chain seafood products?

Chilled cold chain seafood products perform best when you shorten warm exposure and stabilize the internal environment. Chilled seafood doesn’t tolerate long staging. Your biggest wins usually come from workflow discipline first, then packaging tuning.

Chilled solution stack (build in this order)

-

Pre-chill product (packaging can’t “fix” a warm start)

-

Fast pack-out (reduce ambient time)

-

Leak containment (keep meltwater controlled)

-

Right-size insulation (match lane risk)

-

Monitoring samples (learn and improve)

| Chilled lane risk | Packaging pattern | Monitoring level | What it means for you |

|---|---|---|---|

| Short local | light insulation + strict timing | spot checks + sampling | low cost, high discipline |

| Medium regional | stronger insulation + buffered coolant | weekly sampling | better stability |

| Multi-handoff | premium insulation + tighter SOP | more sampling + exceptions | fewer surprises |

Practical tips and suggestions

-

Reduce door-open time during loading. That’s where drift starts.

-

Use a delay trigger: “If delay exceeds X minutes, do Y.”

-

Train “keep it sealed” behavior during staging and receiving.

Practical example: A courier improved chilled stability by loading in route order and limiting lid-open time per stop.

What solutions work best for frozen cold chain seafood products?

Frozen cold chain seafood products fail when they partially thaw and refreeze. That creates texture damage, drip loss after thaw, and “looks refrozen” complaints. Your goal is a stable frozen state with minimal warm events.

Frozen solution stack (keep it simple)

-

keep product fully frozen before pack-out

-

minimize staging time

-

use insulation sized to lane + weather

-

reduce repeated opens during multi-stop delivery

-

define a clear “missed delivery” rule

| Frozen failure risk | What you may see | What to change first | What it means for you |

|---|---|---|---|

| Edge thaw | damp carton, soft corners | stronger insulation + faster handoff | fewer defects |

| Refreeze cycle | large ice crystals | strict exception rules | protects texture |

| Dehydration | frost burn | better sealing and fit | better appearance |

Practical tips and suggestions

-

Avoid repeated “open and search” behavior inside the box.

-

Define a hold/return rule for missed deliveries.

-

Pre-condition containers if stored in warm spaces.

Practical example: A frozen shrimp shipper reduced refreeze complaints after enforcing “missed delivery = return to cold storage.”

Monitoring and proof for cold chain seafood products in 2025

Monitoring should help you answer: where did the risk happen, and what do we change next? You don’t need a logger in every carton. Start with risk-based sampling and exception monitoring.

Monitoring only matters if it changes behavior. If it doesn’t, it becomes expensive noise.

Monitoring options (match to your goal)

| Method | Best use | What it tells you | Effort | Your practical meaning |

|---|---|---|---|---|

| Spot checks | pack-out + receiving | “right now” condition | low | fast decisions |

| Logger sampling | lane validation | full time profile | medium | root cause clarity |

| Connected sensors | high-value export lanes | near real-time drift | higher | intervene faster |

| Visual indicators | last mile quick checks | simple breach signal | low | faster support |

Seafood shipment temperature data logger placement: what tells the truth?

A good placement rule: near a risk point, buffered from coolant.

Don’t place sensors touching ice packs. That creates false confidence.

| Sensor placement | What it captures | What it misses | What it means for you |

|---|---|---|---|

| Next to coolant | best-case temp | warm corners | false comfort |

| Center of payload | average condition | early edge warming | good baseline |

| Near outer wall (buffered) | worst-case trend | little if standardized | best for protection |

What to record (simple but powerful proof)

-

pack-out time and location

-

product temp at pack-out (sampling)

-

shipper type and pack recipe version

-

carrier pickup time

-

receiving time and exceptions

-

corrective actions when issues occur

Practical tips and suggestions

-

Use a placement photo for each pack recipe.

-

Review weekly in 15 minutes. Track peaks and time-out-of-range.

-

Train customer support to ask: “How long was it outside?” not only “Was it warm?”

Practical example: Sampling often reveals cross-dock dwell is the main spike point, not driving time.

Last-mile requirements for cold chain seafood products

Last mile is where cold chain seafood products are most likely to fail. A perfect system can still lose if a box sits on a sunny porch. You can’t control every doorstep, but you can reduce risk with delivery rules and customer messaging.

Last-mile seafood delivery requirements (simple SOP)

-

deliver in cooler windows for high-risk lanes (morning beats afternoon)

-

send “receive now” alerts before arrival

-

instruct safe placement (shade/indoors) when possible

-

reduce open time for multi-stop vehicles (open–grab–close)

-

define what happens when delivery fails (return, pickup, hold)

| Last-mile risk | What causes it | Simple solution | What it means for you |

|---|---|---|---|

| Porch dwell | unattended delivery | alerts + windows | fewer disputes |

| Re-delivery | missed recipient | pickup option | less total exposure |

| Multi-stop openings | searching in boxes | zone labels + route order | fewer spikes |

| Weather exposure | rain/heat | protected placement | less damage |

Practical tips and suggestions

-

Create a “high-risk lane list” that triggers stricter rules.

-

Use a standard message template for heat wave days.

-

Add a receiving checklist card in the box for B2B buyers.

Practical example: A DTC seafood brand reduced claims after shifting deliveries into a tighter window and adding short alerts.

Validation checklist for cold chain seafood products requirements and solutions

Validation proves your pack-outs work on the routes you actually run. It also stops overpacking. Overpacking increases cost and can create moisture issues.

Think of validation like a road test. You don’t judge a vehicle only in the parking lot.

Seafood cold chain validation checklist (lane-based)

| Validation step | What you do | What you measure | What you change after | Your practical win |

|---|---|---|---|---|

| Thermal hold test | simulate real route | time within target | coolant + insulation | fewer excursions |

| Handling test | drop/vibration simulation | leaks/crush | inserts + layout | fewer damage claims |

| Process test | run with real staff | pack time + errors | training + photos | higher consistency |

| Seasonal test | warm + mild days | worst-case behavior | lane rules | fewer surprises |

10-shipment pilot plan (doable in two weeks)

-

Pick two lanes: one stable, one risky.

-

Lock one pack recipe per lane (no improvising).

-

Sample temperature profiles on a subset.

-

Track three outcomes: temp exceptions, leaks, complaints.

-

Change one variable only (size, layout, coolant amount, or handoff time).

-

Repeat until outcomes are repeatable.

Interactive decision tool: choose your solution tier

Step 1: Product risk

-

A) Very high (live shellfish, raw-intended premium items)

-

B) High (fresh chilled fish, cooked chilled seafood)

-

C) Medium (robust frozen items, stable short lanes)

Step 2: Lane risk (count “Yes”)

-

warm ambient exposure likely

-

more than one handoff

-

delivery time uncertain

-

high humidity season

-

buyer requires temperature proof

Tier selection

-

0–1 Yes: Tier 1 (Essentials)

-

2–3 Yes: Tier 2 (Controlled)

-

4–5 Yes: Tier 3 (Critical)

| Tier | What you use | What you must do | What it means for you |

|---|---|---|---|

| Tier 1 | basic insulation + leak control | strict timing | big gains, low cost |

| Tier 2 | stronger insulation + tuned coolant | sampling + exception rules | predictable weekly results |

| Tier 3 | premium insulation + monitoring | strict handoff + proof | protects high-risk lanes |

Practical example: Many teams improve fastest by tightening staging time and lid-open time before changing materials.

2025 developments and trends for cold chain seafood products

In 2025, cold chain seafood products programs are becoming more lane-based and more buyer-evidence driven. Teams are simplifying into two or three validated pack recipes. Monitoring is becoming smarter, with fewer devices but better sampling choices.

Sustainability pressure is rising too. That pushes right-sizing, reusable packaging loops where possible, and fewer reships through better first-time success.

Latest progress snapshot

-

Lane-specific pack recipes: seasonal and route-based variants

-

Faster feedback loops: weekly reviews and one-variable improvements

-

Better wet-proof labeling: treated as quality control, not admin

-

Clearer exception playbooks: fewer random decisions under stress

Internal link strategy suggestions (no external links)

Frequently Asked Questions

Q1: What are the core requirements for cold chain seafood products?

Stable time-temperature control, clean handling, hazard-aware controls, traceability, and verification records.

Q2: What temperature should chilled seafood target?

Many operations use 0–4°C (32–39°F) as a practical working target, then follow buyer specs and local rules.

Q3: What temperature should frozen seafood target?

Many operations aim for ≤−18°C (0°F) to protect frozen state and prevent partial thaw cycles.

Q4: What is the biggest mistake with cold chain seafood products?

Long warm staging and door-open time. Most warming happens during waiting and loading.

Q5: Do I need temperature loggers in every shipment?

Not usually. Start with lane sampling on high-risk routes and add exception monitoring for complaints.

Q6: How do I prevent leaks and cross-contact?

Use a secondary leak barrier, upright inserts, and a receiving rule that holds leaking packs immediately.

Q7: How should I place temperature loggers in seafood shippers?

Place them near an outer wall with a buffer layer, away from direct coolant contact, to capture risk-zone trends.

Summary and recommendations

Cold chain seafood products perform best when you run a system, not a collection of tricks. Set clear chilled and frozen targets, reduce temperature cycling by shortening staging and door-open time, and choose packaging that controls leaks and movement. Use monitoring as a learning tool on high-risk lanes, and validate pack recipes with route-realistic tests. When your SOP is repeatable, you ship with confidence and defend decisions with proof.

Action plan (CTA)

This week, pick your top two lanes and run a 10-shipment pilot. Lock one pack recipe per lane, sample temperature profiles, and track leaks and complaints. Then change only one variable at a time until results are repeatable.

About Tempk

At Tempk, we help seafood teams turn cold chain seafood products requirements and solutions into practical daily workflows. We focus on lane-based pack recipes, wet-proof packaging discipline, monitoring that drives action, and receiving checklists that keep decisions consistent. Our goal is fewer rejections, fewer claims, and a smoother buyer experience without operational overload.

Next step: Share your product category (chilled/frozen/live), lane duration, and handoff count. We can map a lane-based solution tier and a pilot checklist you can run immediately.