Cooler Backpack Distributor: How Do You Choose?

You choose a cooler backpack distributor by proving real-world performance, not trusting a perfect sample. Food safety guidance warns that bacteria grow quickly in the “danger zone,” often described as 40°F–140°F, and can double in as little as 20 minutes. The CDC also says to avoid leaving perishable food out beyond 2 hours (or 1 hour above 90°F). Your distributor choice should help you reduce time and temperature risk, plus returns.

This article will answer

-

How to qualify a cooler backpack distributor for bulk cooler backpack wholesale programs

-

What specs matter most for an insulated backpack cooler for food delivery

-

How to compare a leakproof cooler backpack supplier without guesswork

-

What to ask about cooler backpack distributor MOQ and lead time before you commit

-

How a custom logo cooler backpack bulk program stays on schedule

-

Which 2026 compliance and material questions reduce sourcing risk

What specs should you set before you contact a cooler backpack distributor?

You get better pricing and fewer mistakes when you give your cooler backpack distributor a clear “job description.” Start with route time, payload type, and cleaning reality. If you ship time/temperature control for safety foods, many food-service rules focus on keeping cold foods at 41°F or below and hot foods at 135°F or above. U.S. Food and Drug Administration Your bag spec should support that goal during your typical delivery window.

Define “success” in plain language: fewer spills, less heat loss, faster wipe-down, and fewer zipper failures. Then turn that into five specs: internal size, insulation approach, liner build, closure, and base support. This is how you keep your cooler backpack distributor quoting the same product, not “something similar.”

60-second spec builder for a food delivery cooler backpack distributor program

Pick one option per line, then share it with your cooler backpack distributor.

-

Delivery mode: bike / scooter / van / on-foot

-

Order type: hot meals / chilled groceries / mixed / frozen add-ons

-

Typical route time: 15–30 / 30–60 / 60–120 minutes

-

Main pain point: spills / heat loss / weight / cleaning time

-

Branding: none / simple logo / full private label

| Spec area | What to define | What to ask | What it means for you |

|---|---|---|---|

| Internal size | L × W × H | “What are the true inner dimensions?” | Fewer crushed boxes |

| Insulation | foam type + thickness | “What thickness range is locked?” | More consistent cold time |

| Liner | wipe-clean + leak-resistant | “Are seams welded or stitched?” | Less mess and fewer odors |

| Closure | zipper or roll-top | “Which zipper model is used?” | Fewer returns from failure |

| Base | rigid insert yes/no | “Is there a removable base board?” | Better stability in transit |

Practical tips and recommendations

-

If you ship mixed hot + cold: use dividers or dual compartments to reduce cross-temperature damage.

-

If you deliver drinks or soups: demand a rigid base and a liner that can handle spills.

-

If you train new riders often: favor easy cleaning and rugged zippers over premium looks.

Practical example: One delivery team reduced “tipped order” refunds after switching to a bag with a rigid base insert and a higher liner wall.

How do you qualify a cooler backpack distributor for bulk cooler backpack wholesale?

A strong cooler backpack distributor delivers repeatable batches, not just a good first sample. For B2B, your hidden cost is returns, replacements, and customer support. The best distributor reduces those costs with locked specs, a written QC process, and a fast defect resolution policy. If you operate across multiple locations, you also need stable inventory for 6–12 months.

Treat your distributor like a “stability layer.” You are buying fewer surprises: no foam substitution, no zipper downgrade, and no liner change without approval. This mindset turns a cooler backpack distributor into an operations partner, not a catalog.

The “Distributor Fit Score” self-test

Score each item 0, 1, or 2 points. Total your score.

-

Can the cooler backpack distributor hold inventory for 6–12 months?

-

Do they offer two insulation tiers (standard and premium)?

-

Can they support your branding and packaging needs?

-

Do they have written QC checkpoints and acceptance criteria?

-

Can they trace batches by PO or lot number?

-

Can they ship to multiple locations with carton labels?

-

Do they have a clear samples process and timeline?

-

Do they provide carton-level packing details (units per carton)?

-

Is the defect resolution process written and fast?

-

Can they scale during peak season with a capacity plan?

| Score range | What it means | Your next move | What it means for you |

|---|---|---|---|

| 16–20 | Strong candidate | Pilot and lock specs | Lower return risk |

| 11–15 | Viable with controls | Put QC in writing | Fewer surprises |

| 0–10 | High risk | Keep searching | Avoid costly rework |

Practical tips and recommendations

-

If you launch in multiple cities: ask for a capacity plan, not a promise.

-

If you run subscriptions: lock zipper model and liner thickness in writing.

-

If branding matters: approve logo placement on real fabric, not mockups.

Practical example: A retailer avoided a reprint problem by requiring a photo proof on the actual bag fabric.

How do you test insulation performance from a cooler backpack distributor?

A cooler backpack distributor should help you test performance with simple, repeatable methods. “High insulation” can mean many things, and the zipper is often the weak point. Also, you will see two “danger zone” ranges: consumer guidance often says 40°F–140°F, while food-service materials often use 41°F–135°F for TCS foods. Both point to the same idea: avoid spending time in the middle.

Your goal is not a lab-perfect number. Your goal is stable temperature under real use: opening, closing, and carrying. That is why a field-style test beats marketing claims from a cooler backpack distributor.

A one-day retention test you can run (no lab needed)

-

Use the same payload, same cold packs, and same starting temperature.

-

Put a thermometer inside the bag and close it.

-

Measure internal temperature every hour for 8–12 hours.

-

Repeat once with the bag opened every hour (real-life stops).

-

Compare results across two bags from your cooler backpack distributor.

| Test condition | What you measure | Pass signal | What it means for you |

|---|---|---|---|

| Closed bag | warming rate | slower warming | Better for long routes |

| Open/close cycles | stability | smaller spikes | Better for stop-and-go |

| Zipper area | heat leak | fewer corner gaps | Fewer “warm food” claims |

| Base support | shape under load | less sag | Fewer spills and crush |

Practical tips and recommendations

-

For food delivery: test open/close cycles, not only closed storage.

-

For grocery delivery: test condensation and liner wipe-down time.

-

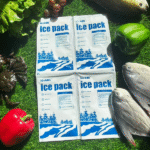

For frozen add-ons: add an ice-pack sleeve or insert system.

Practical example: One operator learned zipper quality mattered more than thicker foam during frequent stops.

What makes a leakproof cooler backpack supplier truly “leakproof”?

A leakproof cooler backpack supplier is only “leakproof” if seams, corners, and zipper ends stay sealed after flexing. Most leaks start at stress points: bottom corners, stitched seams, and zipper paths. Your cooler backpack distributor should explain liner construction in plain terms and show how they prevent seepage.

If you ship wet items, leaks become a top KPI. Even if you use gel packs, condensation and cleaning still make leak resistance valuable. Leak control protects your customer experience, not just your product.

A 15-minute leak test you can run today

-

Place dry paper towels under the bag.

-

Fill the liner with water to a safe level.

-

Wait 10 minutes, then tilt in four directions.

-

Check corners, seams, and zipper ends.

-

Repeat after bending the bag 20 times.

| Leak risk area | What fails | What to ask your cooler backpack distributor | What it means for you |

|---|---|---|---|

| Bottom corners | abrasion and stress | reinforced corners | longer bag life |

| Seam lines | stitch holes | welded or sealed seams | fewer leak complaints |

| Zipper ends | gaps | better zipper design | cleaner deliveries |

| Drain plug | poor seal | consistent plug spec | fewer surprise leaks |

Practical tips and recommendations

-

If customers use loose ice: require sealed seams and corner reinforcement.

-

If you ship seafood: prioritize odor-resistant liners and easy cleaning.

-

If you sell premium: add a clear leak defect policy before scaling.

Practical example: A subscription program reduced “wet bag” tickets after switching to sealed seams and higher liner walls.

How do cooler backpack distributor MOQ and lead time affect your cash and stockouts?

Cooler backpack distributor MOQ and lead time decide whether you scale smoothly or get stuck with the wrong inventory. MOQ controls your cash risk. Lead time controls your stockout risk. Ask for production time and shipping time separately, because delays hide in the second part.

Your safest path is staged buying. You learn with a pilot, then lock specs, then scale. This is how you keep a cooler backpack distributor from becoming a “warehouse problem” when demand shifts.

A safer bulk buying workflow (HowTo style)

-

Start with samples: run cold-hold, carry, and cleaning tests.

-

Run a pilot batch: 50–200 units for real feedback.

-

Lock specs: materials, zipper model, liner thickness, stitching method.

-

Confirm packaging: carton count, labels, barcodes, inserts.

-

Scale in steps: increase volume only after the pilot is stable.

The “3-box rule” for sample testing

Request three samples, not one.

-

One for cold-hold testing

-

One for load-and-carry testing (5–10 kg)

-

One for cleaning and odor testing

| Buying stage | Typical unit range | Main goal | What it means for you |

|---|---|---|---|

| Samples | 1–3 | prove fit and basics | faster decisions |

| Pilot | 50–200 | learn real failure modes | lower cash risk |

| First bulk | 500–2,000 | stabilize quality | fewer returns |

| Reorders | recurring | optimize cartons and cost | better margins |

Practical tips and recommendations

-

If MOQ is high: ask for mixed colors under one material family.

-

If seasonality is real: reserve capacity early and ship in waves.

-

If you deliver to multiple sites: require carton labels by location.

Practical example: A buyer avoided overstock by splitting the first bulk order into two shipments.

How does a custom logo cooler backpack bulk program stay on schedule?

A custom logo cooler backpack bulk program succeeds when you standardize decisions early. Branding is where delays and rework hide: logo placement, color matching, and approval cycles. Your cooler backpack distributor should offer a clear process: proof, pre-production sample, then mass production.

Avoid vague approvals. Approve one “golden sample” and lock it. Then every future batch should match that sample. This is how you keep a cooler backpack distributor accountable without conflict.

Branding methods explained in plain language

| Branding option | Best for | Typical risk | What it means for you |

|---|---|---|---|

| high volume promos | fading over time | fastest launch | |

| Embroidery | premium gifting | fabric distortion | higher perceived value |

| Patch | consistent bulk | extra step | strong brand control |

Practical tips and recommendations

-

Approve on real fabric: request a photo proof on the actual bag.

-

Standardize one placement: fewer variations means fewer mistakes.

-

Decide packaging early: cartons and inserts affect damage rates.

Practical example: A program reduced rework by using a “placement template photo” for every batch.

What compliance and materials questions should you ask a cooler backpack distributor in 2026?

In 2026, your cooler backpack distributor must answer material and compliance questions up front. For food delivery, your “why” is safety and consistency. The CDC warns about time limits for perishable foods, especially in heat. Many food-service references also recommend holding cold foods below 41°F and hot foods above 135°F. U.S. Food and Drug Administration

You also have platform and market constraints. For example, Uber publishes insulated bag minimum dimensions for standard, pizza, and large orders. Uber If you support courier fleets, those dimensions can shape your SKU plan and sizing options.

Finally, material scrutiny is rising. France’s Law No. 2025-188 sets restrictions starting January 1, 2026 for certain PFAS-containing consumer product categories, with further textile provisions by 2030. Légifrance If you sell into Europe or supply global brands, your cooler backpack distributor should be ready to discuss coatings, declarations, and testing plans.

2026 compliance quick checklist

| Topic | Why it matters | What to request | What it means for you |

|---|---|---|---|

| Bill of materials | avoids substitutions | full material list | stable performance |

| Waterproof coating | affects cleaning and rules | coating type + declaration | fewer compliance surprises |

| Liner hygiene | reduces odors | cleaning guidance | better reviews |

| Platform sizing | avoids rejection | size options and proofs | faster onboarding |

| Traceability | speeds recalls | PO-to-batch mapping | lower risk |

Practical tips and recommendations

-

If you sell internationally: ask for market-specific declarations early.

-

If waterproofing is critical: confirm coating details and any restricted-substance policies.

-

If hygiene is critical: choose smoother liners with fewer internal seams.

Practical example: A fleet reduced onboarding friction by standardizing one bag size that met platform minimums.

2026 latest cooler backpack distributor developments and trends

Cooler backpacks are shifting from “outdoor gear” to daily logistics equipment. Buyers want fewer returns, faster cleaning, and more consistent sizing. Platform guidance around insulated bag dimensions also pushes standardization. Uber Material questions, including PFAS, are becoming part of sourcing calls in 2026. Légifrance

Latest progress at a glance

-

Easier-to-clean liners: smoother surfaces that trap fewer odors

-

Stronger closures: zipper reinforcement to reduce early failures

-

Modular interiors: removable dividers for mixed hot/cold loads

-

More material declarations: clearer documentation for regulated markets

Market insight you can use: customers forgive small differences in “hours cold.” They do not forgive leaks or broken zippers. So the best cooler backpack distributor in 2026 wins on durability and process, not marketing claims.

Cooler backpack distributor FAQs

Q1: How do I choose a cooler backpack distributor quickly?

Use a scorecard and demand samples. Run a retention test and a 15-minute leak test. Then pilot 50–200 units. A fast pilot beats a long debate.

Q2: What should I prioritize for an insulated backpack cooler for food delivery?

Prioritize easy cleaning, leak resistance, zipper durability under frequent opening, and comfort under load. If riders hate the bag, it will not be used.

Q3: What should I ask about cooler backpack distributor MOQ and lead time?

Ask for pilot MOQ options and separate timelines for production and shipping. Request a written schedule you can plan around.

Q4: What makes a leakproof cooler backpack supplier program succeed?

Welded or sealed seams, reinforced corners, and a repeatable leak test. Also define defect handling rules before scaling.

Q5: Do delivery platforms have bag size expectations?

Some do. For example, Uber publishes minimum insulated bag dimensions for standard, pizza, and large orders. Uber Match your SKU plan to the sizes you must support.

Q6: Why are PFAS questions showing up in 2026 sourcing calls?

Some markets are tightening PFAS restrictions in consumer products. France’s Law No. 2025-188 includes provisions that start January 1, 2026. Légifrance If you sell globally, ask for declarations early.

Summary and recommendations for choosing a cooler backpack distributor

A cooler backpack distributor should help you deliver stable quality, not just a low unit price. Focus on leak resistance, zipper durability, and repeatable insulation performance under real routes. Reduce risk with the 3-box sample rule, a 50–200 unit pilot, and a locked spec sheet. When you choose the right cooler backpack distributor, you protect margins and reduce returns.

Next steps: write your one-page spec, shortlist two distributor candidates, and run a two-week pilot with documented tests. If the pilot stays stable, scale in steps with QC criteria in writing.

About Tempk

At Tempk, we help B2B teams turn delivery reality into simple specs, repeatable tests, and scalable rollout plans. We focus on practical performance: stable insulation, lower leakage risk, and consistent QC across batches. We also help you standardize packaging and distribution steps, so your cooler backpack distributor program stays predictable as volume grows.

Next step: Share your use case, target route time, and branding level. We will suggest a distributor-ready spec sheet and a pilot test checklist your cooler backpack distributor can follow.