How to Choose the Best Insulated Box Liner Factory for Cold Chain Logistics in 2026?

Introduction:

Selecting the best insulated box liner factory is essential for effective cold chain logistics. As the demand for temperature-sensitive products continues to grow in 2026, especially in pharmaceuticals, food, and biopharmaceuticals, a reliable factory ensures that your shipments remain intact and at the correct temperature. In this guide, we will explore the key factors that affect factory choice, including material performance, customization, sustainability, and regulatory compliance.

This article will help you answer:

How do materials impact the performance of insulated box liners?

What customization options should an ideal factory provide?

How does sustainability influence factory selection?

What are the latest trends in insulated box liner manufacturing for 2026?

What Makes an Insulated Box Liner Factory Stand Out in 2026?

Core Answer:

A top insulated box liner factory in 2026 offers more than just basic insulation products. They provide tailored solutions to ensure optimal temperature control, support sustainability goals, and comply with strict quality standards. Look for factories that integrate advanced materials, customize designs, and maintain transparency in their production processes.

Key Evaluation Criteria:

| Criteria | Why It Matters | Outcome for You |

|---|---|---|

| Material Expertise | The factory should offer a variety of high-performance insulation materials. | Better temperature control and reduced spoilage. |

| Customization Services | Custom liners tailored to your exact packaging needs. | Enhanced insulation performance and packaging efficiency. |

| Quality Certifications | Look for certifications like ISO 9001 and Good Distribution Practices (GDP). | Compliance with industry standards and improved reliability. |

| Sustainability Initiatives | Factories using recyclable and eco-friendly materials. | Support for your sustainability goals and lower environmental impact. |

How Do Insulation Materials Impact Performance?

Core Answer:

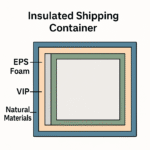

Material selection directly influences the thermal performance, durability, and weight of the insulated box liner. A reputable factory will provide a range of options to meet your shipment’s specific temperature control requirements. Choosing the right material is critical for ensuring that your products stay within safe temperature ranges during transit.

Common Materials and Their Benefits:

Polyurethane Foam: Excellent for long-duration shipments, offering high thermal resistance, though it is heavier.

Reflective Foil with Bubble Wrap: Lightweight and cost-effective, ideal for short transit times.

Recyclable PET Liners: Eco-friendly, providing high thermal performance with a lighter footprint.

Paper-Based Insulation: Ideal for short-term use with a high sustainability profile.

Material Performance Breakdown:

| Material Type | Thermal Performance | Weight | Sustainability |

|---|---|---|---|

| Reflective Foil + Bubble Wrap | Moderate to High | Low | Medium |

| Polyurethane Foam | Very High | High | Medium |

| PET Recyclable Liners | High | Medium | Very High (curbside recyclable) |

| Paper-Based Insulation | Moderate | Medium | High |

Why Material Choice Matters to You:

Selecting the right material ensures that your shipment remains within the desired temperature range, reduces shipping costs, and aligns with sustainability initiatives. A factory should provide transparent performance data to help you make an informed decision.

Why Customization from Insulated Box Liner Factories Matters

Core Answer:

Customization is a critical aspect of choosing the right factory. Off-the-shelf liners often fail to provide the best insulation, leading to inefficiency and product loss. Custom liners are designed to fit specific box dimensions and temperature requirements, ensuring that there are no gaps that could lead to temperature fluctuations.

Customization Benefits:

Improved Fit: Custom liners are designed to match your exact box sizes, ensuring no gaps for heat transfer.

Enhanced Insulation: Tailored solutions enhance thermal performance by adjusting insulation thickness or using multi-layer designs.

Cost Savings: Customized liners reduce the need for excess cooling agents like ice packs, which cuts logistics costs.

Why Customization Matters:

A custom-built liner ensures that your products are optimally protected throughout transit, reducing spoilage, waste, and shipping costs. This leads to better cold chain efficiency and lower overall expenses.

What Quality Certifications Should You Check for?

Core Answer:

Quality certifications are essential to verify that the factory follows strict standards and produces reliable, safe products. Look for factories that are ISO certified, follow Good Distribution Practices (GDP), and have the necessary FDA approvals for food and pharmaceutical packaging.

Key Certifications to Request:

ISO 9001: Ensures that the factory follows a quality management system that meets customer and regulatory requirements.

Good Distribution Practice (GDP): Critical for pharmaceutical packaging, ensuring proper temperature control.

FDA Compliance: For food and pharmaceutical applications, ensuring that materials used are safe.

Sustainability Certifications: Look for certifications like FSC or Cradle to Cradle to ensure that materials are eco-friendly.

Why Certifications Matter:

Certifications protect your business by ensuring that your liners meet industry standards, reducing regulatory risks, and guaranteeing product safety. They also reflect the factory’s commitment to quality and consistency.

What Are the Key Trends in Insulated Box Liner Manufacturing for 2026?

Core Answer:

The insulated box liner manufacturing industry is evolving rapidly. Trends such as smart packaging, eco-friendly materials, and hybrid insulation systems are shaping how factories design and produce liners. Staying ahead of these trends ensures that you can offer cutting-edge solutions in your cold chain logistics operations.

Latest Trends to Watch:

Smart Packaging Integration: Temperature sensors embedded in liners allow for real-time monitoring of shipments.

Recyclable and Eco-Friendly Materials: Factories are moving towards biodegradable and recyclable options to meet environmental goals.

Hybrid Insulation Systems: Combining passive insulation with active cooling methods, such as phase change materials (PCMs), enhances temperature control.

Automation in Production: Increasing automation speeds up production and ensures more precise and consistent manufacturing processes.

How These Trends Benefit You:

By adopting these innovative trends, your company can improve cold chain efficiency, reduce environmental impact, and provide better service to your customers. It also ensures that your business remains competitive and compliant with regulatory standards.

How Do You Evaluate Price vs. Value When Choosing a Factory?

Core Answer:

While price is always a consideration, it should not be the only factor when choosing an insulated box liner factory. Low-cost liners might offer short-term savings, but they often come with hidden costs like poor insulation performance and higher spoilage rates. It’s essential to evaluate the total cost of ownership, which includes product durability, thermal performance, and the long-term savings from reduced waste and better packaging efficiency.

Key Considerations:

Material Performance vs. Price: Higher-quality materials may cost more upfront but save money in the long run by reducing spoilage.

Customization vs. Stock Products: Custom solutions might have higher initial costs but can improve shipping efficiency and reduce waste.

Sustainability vs. Cost: Eco-friendly materials might be more expensive but help your company align with sustainability goals and improve brand reputation.

Why It Matters:

Evaluating cost vs. value ensures that you’re investing in the most reliable, cost-effective solution for your business. Don’t cut corners by focusing solely on price, as poor performance can lead to higher long-term costs.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of an insulated box liner?

Most insulated box liners can last up to 12–72 hours, depending on material type and design. Some high-quality liners are reusable, especially those made with durable materials like PET or foam composites.

Q2: How do I know which material is best for my shipment?

Choose a material that aligns with your temperature range, transit duration, and sustainability goals. For long shipments, foam or multi-layer options might be best, while for shorter shipments, reflective foil with bubble wrap may be sufficient.

Q3: Are sustainable liners effective?

Yes, many recyclable PET liners and biodegradable materials now provide similar or even superior thermal performance compared to traditional foam liners.

Summary & Recommendations

Key Takeaways:

Selecting the right insulated box liner factory is crucial for ensuring thermal performance, cost efficiency, and regulatory compliance.

Customization is key to reducing waste and improving efficiency.

Sustainability is a critical consideration in 2026, with a shift towards eco-friendly materials and processes.

Next Steps:

Define your product’s temperature requirements and transit duration.

Request samples and test data from multiple factories.

Conduct pilot tests under real-world conditions to evaluate performance.

By following these steps, you can ensure that you partner with the right factory, resulting in cost-effective and reliable cold chain solutions.

About Tempk

At Tempk, we specialize in high-performance insulated box liners tailored to your cold chain logistics needs. We focus on innovation, customization, and sustainability to provide you with the best solutions for your temperature-sensitive shipments.

Action:

Contact us today for expert advice on choosing the best insulated box liner factory and optimizing your cold chain operations.