Cold Chain Dry Ice Pack Sheets: How Do They Revolutionize Temperature-Sensitive Shipping?

Managing temperature-sensitive logistics in 2025 means optimizing your cold chain processes with the latest advancements in refrigeration. Cold chain dry ice pack sheets have emerged as a game-changer, providing a highly efficient and eco-friendly solution for maintaining sub-zero temperatures. In this guide, we will explore how these sheets work, their key benefits, and best practices for their use in modern logistics.

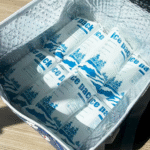

What Are Cold Chain Dry Ice Pack Sheets and How Do They Work?

Cold chain dry ice pack sheets are engineered cooling materials that combine dry ice technology with advanced polymer encapsulation. These sheets are filled with CO₂ pellets or dry ice flakes, which are sealed inside flexible, high-strength pouches that slowly release cooling energy through sublimation. Unlike traditional dry ice blocks, these sheets offer better surface contact and uniform cooling, which makes them ideal for transporting delicate items such as vaccines or laboratory samples.

When exposed to ambient temperatures, the solid CO₂ inside sublimates—turning directly from solid to gas—and absorbs heat in the process. This continuous phase change keeps your products within the target temperature range, far longer than traditional cooling methods such as gel packs or water ice.

How Dry Ice Pack Sheets Compare to Traditional Cooling Methods

| Cooling Method | Temperature Range | Duration | Key Advantage | Best Use Case |

|---|---|---|---|---|

| Water Ice Packs | 0°C | 12–24 hrs | Non-toxic, reusable | Short-distance food delivery |

| Gel Ice Packs | -10°C | 24–48 hrs | Consistent cooling | E-commerce meal kits |

| Dry Ice Pack Sheets | -78.5°C | 48–120 hrs | Ultra-low freezing point, no residue | Pharmaceuticals, meat, vaccines |

Dry ice pack sheets help avoid thawing and water damage, ensuring that temperature-sensitive goods such as vaccines, seafood, or diagnostic samples remain stable, even during transit delays.

The Main Advantages of Cold Chain Dry Ice Pack Sheets

-

Extended Cooling Duration:

Dry ice pack sheets maintain ultra-low temperatures for up to five days, depending on packaging insulation and ambient conditions. This makes them ideal for international shipments where delays are more common. -

Cleaner and Safer Cooling:

Unlike block dry ice, which can release gas rapidly, dry ice sheets control sublimation through a multi-layer film design, preventing bursts or leaks. This makes handling safer, especially in pharmaceutical or food environments. -

Space and Weight Efficiency:

Their flat, flexible design allows for easier storage and more efficient use of space inside coolers or thermal boxes. You can even cut or fold them to fit your packaging layout, minimizing wasted volume. -

Environmentally Responsible:

Dry ice is produced from recycled CO₂, meaning it does not contribute to additional greenhouse emissions. Paired with reusable polymer layers, these sheets meet the eco-conscious logistics standards expected in 2025.

How to Use Cold Chain Dry Ice Pack Sheets Effectively

To get the most out of dry ice pack sheets, proper handling is crucial. Here’s a guide for effective use:

-

Pre-condition the Sheets:

Store them in a -80°C freezer for at least 24 hours before use to ensure they perform optimally. -

Insulate Properly:

Use EPS, polyurethane, or vacuum-insulated panels to minimize heat exchange and keep the cold where it’s needed. -

Plan for Sublimation:

Always allow space in your cooler for gas expansion as the dry ice sublimates. -

Monitor Shipment Temperature:

Use temperature data loggers to ensure the cold chain remains intact throughout the shipping process.

Practical Tips for Different Products

-

Seafood: Layer dry ice sheets above and below the fish to ensure even cooling.

-

Vaccines: Place sheets on the sides to prevent direct contact and thermal shock.

-

Meat Shipments: Combine dry ice sheets with thermal liners for extended cold retention, up to 96 hours.

Safety Reminder

Always handle dry ice sheets with insulated gloves and avoid using airtight containers to prevent pressure build-up.

Key Applications of Dry Ice Pack Sheets in Cold Chain Logistics

Pharmaceuticals and Biotech Logistics

Dry ice pack sheets are crucial for transporting biological samples, vaccines, and gene therapy materials that require stable temperatures below -60°C. Their even cooling distribution minimizes the risk of temperature excursions, which can compromise sensitive materials.

Food and Seafood Transportation

Frozen meat, seafood, and dairy products benefit from dry ice pack sheets by maintaining temperature stability during long-haul transport. These sheets can be easily layered between boxes to preserve freshness without introducing moisture.

E-commerce Meal and Grocery Delivery

As the online food delivery sector grows, dry ice pack sheets are increasingly used for home deliveries of frozen meals, ensuring food quality remains intact even after extended last-mile delivery times.

Laboratory and Diagnostic Samples

Research institutes rely on dry ice sheets to safely transport DNA samples, tissue cultures, and enzymes, ensuring sample integrity and preventing contamination with dry, residue-free cooling.

Comparing Dry Ice Pack Sheets to Other Alternatives

| Feature | Dry Ice Pack Sheets | Traditional Dry Ice Blocks | Gel Ice Packs |

|---|---|---|---|

| Cooling Duration | 48–120 hrs | 24–72 hrs | 12–36 hrs |

| Handling Safety | High | Medium | High |

| Temperature Stability | Excellent | Good | Moderate |

| Water Leakage | None | None | Low |

| Reusability | Partial | Single-use | Reusable |

| Eco-Impact | CO₂-neutral | CO₂-neutral | Plastic waste |

Why Choose Dry Ice Pack Sheets Over Alternatives?

The flexible film structure of dry ice pack sheets ensures gradual gas release, making them safer for both air and ground shipping compared to loose dry ice pellets. Their reusability and eco-friendly design also make them a more cost-effective and environmentally responsible option.

How to Select the Right Dry Ice Pack Sheet for Your Cold Chain

-

Determine Temperature Requirements:

Identify the critical temperature range for your product:-

Vaccines: Below -60°C

-

Meat and Seafood: -20°C to -30°C

-

Biotech Samples: -70°C

-

-

Choose the Correct Sheet Thickness:

-

Thin sheets (2–3mm): Ideal for short-distance or air shipments.

-

Medium sheets (4–6mm): Best for cooling up to 72 hours.

-

Thick sheets (8mm+): Perfect for extended transit or unstable environments.

-

-

Assess Packaging Volume:

Use modular sheets that fit your container dimensions. Overpacking results in wasted space and unnecessary dry ice capacity.

Innovations in Cold Chain Dry Ice Pack Sheets (2025)

-

Smart Temperature Sensors:

In 2025, more manufacturers are integrating IoT-enabled thermal sensors into dry ice sheets for real-time temperature tracking. -

Bio-based Polymer Films:

New dry ice pack sheets use biodegradable polymer layers to reduce environmental impact without compromising cooling efficiency. -

Automated Production Lines:

Automation technologies improve the precision CO₂ filling process, enhancing the uniformity and safety of each sheet produced. -

Global Expansion:

The global cold chain packaging market is set to reach USD 94 billion by 2025, with dry ice pack sheets leading the innovation segment.

Frequently Asked Questions (FAQ)

Q1: How long can cold chain dry ice pack sheets keep products frozen?

Dry ice sheets can maintain freezing temperatures for 48 to 120 hours, depending on the thickness, insulation, and environmental conditions.

Q2: Are dry ice pack sheets safe for air shipping?

Yes, dry ice pack sheets comply with IATA regulations, provided the packaging is vented to release CO₂ gas safely.

Q3: Can dry ice sheets be reused?

Some hybrid models can be refrozen and reused for short-duration shipments, but most are designed for single-use due to the sublimation process.

Conclusion and Next Steps

Cold chain dry ice pack sheets are revolutionizing temperature-controlled logistics by providing longer-lasting cooling, safer handling, and a more sustainable solution. With their ability to meet the demands of industries like pharmaceuticals, biotech, and perishable foods, these sheets are crucial for your cold chain needs in 2025.

To optimize your cold chain logistics:

-

Select the right sheet thickness and insulation.

-

Monitor temperature conditions with data loggers.

-

Always adhere to safety protocols when handling dry ice.

For a customized solution, contact Tempk today to discuss the ideal dry ice pack sheet configuration for your products and ensure your cold chain is future-ready.