Cold Chain Sugar-Free Chocolate Regulations (2025)

In 2025, cold chain sugar-free chocolate regulations are stricter and more complex than ever. If you manufacture, transport, or sell sugar-free chocolate, you must keep it safe, high-quality, and fully compliant from factory to store. Non-compliance can lead to spoiled products, regulatory fines, or lost customer trust. This guide – packed with industry insights and the latest data – helps you navigate global standards confidently so you can protect your product quality and reputation.

This article will answer:

Global guidelines for manufacturers: How sugar-free chocolate producers ensure labeling, safety, and cold chain compliance.

Logistics best practices: What cold chain logistics providers must do to maintain temperature and meet regulations during transport.

Retailer responsibilities: How retailers should store and handle sugar-free chocolates to stay compliant and preserve quality.

Latest 2025 trends: New regulations and technologies shaping cold chain standards for chocolates (with up-to-date data).

Practical tips & FAQs: Actionable advice and answers to common questions about cold chain and sugar-free chocolate rules.

Manufacturers: What Cold Chain Regulations Must You Follow?

Manufacturers of sugar-free chocolate face strict food safety and labeling regulations across global markets. Right from production, you need to control temperature, hygiene, and labeling to meet standards. For example, “sugar-free” labeling is legally defined – in the US it means <0.5g of sugars per serving (FDA) and in the EU it means <0.5g per 100g. Compliance with these definitions and proper ingredient disclosure is mandatory. Manufacturers must also implement Good Manufacturing Practices (GMP) and HACCP (hazard analysis and critical control points) systems to prevent contamination. This includes keeping production areas cool (around 18 °C) to avoid chocolate bloom and spoilage. In 2025, new rules like the EU’s heavy metal limits (introduced July 2025) demand rigorous quality testing for things like cadmium and nickel in cocoa products. In short, you are expected to prove that your sugar-free chocolates are produced safely, honestly labeled, and kept within safe temperature and humidity ranges from the moment they’re made.

[

As a manufacturer, you should start with the core of compliance – the product itself. Use approved sugar substitutes and ensure your formulation meets all labeling criteria for “sugar-free.” For instance, if you claim “no added sugar,” check that you’re following each region’s rule (the EU requires an additional note if the product contains sweeteners or if excessive consumption may have laxative effects from sugar alcohols). Beyond the label, temperature control in your factory and warehouse is crucial. Chocolate is sensitive: too warm and it melts or develops fat bloom; too cold and it can crack or get sugar bloom when warming up. Global food safety standards (like ISO 22000 or FSSC 22000) recommend keeping chocolate in a cool, dry environment (about 12–20 °C and <50% humidity). Many top manufacturers maintain climate-controlled production lines and storage to prevent quality issues. This not only meets any regulatory expectations for product integrity but also reduces waste. Additionally, traceability is a growing focus in 2025 – regulators and large retailers want to track products from cocoa source to store shelf. Ensure you have lot codes and records for ingredients and shipments. If you export globally, remember to register with foreign authorities where required (for example, China now requires overseas manufacturers to register and provide detailed safety documentation). Adhering to these manufacturing guidelines means you’re less likely to face recalls, import rejections, or compliance fines, and you build trust with both regulators and customers.]

Meeting Labeling and Safety Standards

Detailed compliance involves several key aspects for manufacturers:

| Requirement | Example Standard (2025) | Benefit to You |

| “Sugar-Free” Labeling | <0.5 g sugars per serving (FDA); <0.5 g/100g (EU). Must note if contains sugar alcohols. | Legal labeling avoids fines and consumer trust issues. |

| Production Temperature Control | Maintain ~16–20 °C in mixing, tempering, and packaging areas. Monitor humidity <50%. | Prevents chocolate bloom and spoilage, ensuring quality. |

| Quality Testing & Audits | Test for contaminants (heavy metals per EU limits, 2025) and purity. Regular GMP audits. | Ensures safety compliance, avoids recalls (protects brand reputation). |

| Traceability Records | Batch codes, ingredient origins logged. Meet traceability rules (e.g. FSMA 204 in the US by 2026 for high-risk foods). | Quick recall capability, meets import/export rules (smooth market access). |

Practical tips for manufacturers

Design for Stability: Use formulations and packaging that tolerate minor temperature swings. For example, consider adding a thermal insulation layer in bulk chocolate packaging or using moisture-barrier wrappers. This helps if cold chain breaks briefly during distribution.

Include Storage Instructions: Clearly print “Store in a cool, dry place (12–20 °C)” on your sugar-free chocolate packaging. This isn’t just consumer advice – it guides every handler (warehouse, retailer, customer) and provides a basis if a distributor mis-handles the product.

Invest in Monitoring: Place data loggers in your storage facilities and even in outbound pallets. Many manufacturers now use IoT sensors to continuously record temperature/humidity. These records prove your compliance and quickly alert you to any cooling system issues, reducing spoilage.

case: A premium chocolate maker in India discovered rising customer complaints each summer due to heat-damaged “sugar-free” chocolates. In response, they invested in air-conditioned storage and strict temperature monitoring at the plant. As a result, melt incidents dropped dramatically – the company recorded a 30% reduction in product returns during the 2024 summer season. This real-world fix not only kept them compliant with food safety norms, but also improved customer satisfaction and protected their brand’s reputation.

Logistics Providers: Ensuring a Reliable Cold Chain in Transit

For logistics companies, the core rule is to maintain the cold chain – keep sugar-free chocolates within safe temperatures throughout transportation. While chocolate isn’t a “perishable” like dairy or meat, it requires climate control in warm conditions to preserve quality. Regulations in many regions treat improper temperature control as a food safety hazard. For example, the US FDA’s Sanitary Transportation Rule (part of FSMA) mandates that carriers prevent food adulteration during transit – meaning if you’re shipping chocolate through hot environments, you must use adequate cooling or insulation. In Europe, similar hygiene regulations require that transported foods are not exposed to conditions that could make them unsafe or lower quality. Practically, this means using refrigerated trucks or insulated boxes when needed, and training staff on handling temperature-sensitive goods. Logistics providers should also follow any specific instructions from the manufacturer (if the chocolate producer says “keep below 18 °C,” that becomes a handling requirement). Documentation and tracking are critical: regulators and clients may ask for proof that the cold chain was unbroken. In 2025, digital solutions are often expected – many shippers use GPS trackers with temperature sensors to log data in real time. Additionally, international standards like ISO 23412:2020 provide guidelines for refrigerated delivery services, which, while not law, can help demonstrate best practices. In short, as a 3PL or transporter handling sugar-free chocolate, you are responsible for preventing melt and degradation in transit, and showing that you took all reasonable steps to do so.

[

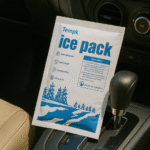

Cold chain logistics for chocolate involve careful planning and robust systems. Before transit, ensure the chocolate is pre-cooled to the right range (around 15–18 °C is ideal for most sugar-free chocolates). Packaging matters: many companies now use passive cooling packaging – insulated shipping boxes with gel ice packs or phase-change materials – especially for last-mile delivery. These solutions can keep chocolates at a steady cool temperature for 24–48 hours without active refrigeration. They’re very useful for e-commerce orders or air shipments. For longer hauls by road, refrigerated trucks (reefers) set to about 15 °C can do the job. Make sure to calibrate the reefer units; chocolate should not be frozen or too cold either, as that can cause cracks or sugar bloom when it warms up. Staff training is a regulatory expectation under food transport rules – drivers and warehouse workers should know to load chocolate quickly (minimize time on the dock under the sun) and never shut off cooling to save fuel. In the US, failure to meet these standards can violate FSMA; in the EU, it could breach the Cold Chain Protocols or general food safety law. Many big retail clients audit their logistics partners on these practices. Recording the journey is another must: use temperature data loggers in shipments and maintain those records. In fact, China’s import rules as of 2025 explicitly require preserving cold-chain logs for certain foods to pass customs checks (for meats currently, but it signals the trend for all foods)(China GACC, 2025). Embracing technology not only keeps you compliant but also provides an extra layer of quality assurance. If an excursion (temperature spike) happens, having an alert system means you can take action – like rerouting the shipment to a nearer cold storage or notifying the receiver. By strictly controlling conditions and documenting everything, logistics providers ensure that sugar-free chocolates arrive as pristine as when they left the factory, meeting both regulatory requirements and customer expectations.]

Temperature Control On the Move

Logistics providers should address several critical points to maintain compliance and chocolate quality:

Validated Cooling Systems: Use trucks or containers with verified temperature control. For small shipments, consider qualified insulated shippers tested specifically for chocolates. These systems keep products between 12–20 °C even if outside weather is extreme.

Route and Timing Planning: Plan transport routes to avoid excessive heat exposure. For example, schedule departures at night or early morning during summer, when temperatures are lower. Shorten transit times where possible. Some companies in hot climates only ship chocolates early in the week to avoid weekend warehouse delays without cooling.

Real-Time Monitoring: Install tracking devices that send real-time temperature data. If a refrigeration unit fails or temperatures drift out of range, an alert can be sent immediately to initiate corrective action. This proactive approach can save a shipment from ruin and shows due diligence to inspectors or clients.

case: A European logistics firm contracted to deliver gourmet sugar-free chocolates to the Middle East had to traverse very hot conditions. They implemented a strict protocol: each pallet was fitted with a Bluetooth temperature logger, and drivers’ cabins got alert notifications if any pallet’s temperature went above 20 °C. In one instance, an alert notified the driver of a rising temperature due to a malfunctioning truck cooler. The driver immediately stopped at a certified cold storage facility en route to fix the issue, preventing a full melt disaster. The result: zero product loss and an on-time, compliant delivery. The client noted this incident as proof of the carrier’s reliability, and it became a case study in how real-time monitoring can safeguard quality and fulfill regulatory obligations.

Retailers: Storing and Selling Sugar-Free Chocolate Safely

Retailers are the final link in the cold chain, and they also have a responsibility to uphold standards for sugar-free chocolate. Even the best-made and well-transported product can be ruined at the store if not handled correctly. Key regulations for retailers revolve around food safety and quality preservation. Generally, laws in most countries require retailers to store food products according to the producer’s instructions and to not sell any food that is unsafe or significantly compromised in quality. For chocolate (especially sugar-free varieties that consumers often buy for health or dietary reasons), this means keeping it in a cool, dry place on-site. Grocery chains and specialty shops should ensure that chocolates are not placed in direct sunlight, near heating vents, or in overly warm stockrooms. In hot climates, many retailers turn up air conditioning or use refrigerated display cases for chocolate; while not explicitly mandated by law, failing to do so can lead to “adulterated” products (melted, re-hardened chocolate with bloom) which might violate consumer protection regulations. Stock rotation is another important practice: retailers must check expiry or “best by” dates and follow first-in-first-out (FIFO) to ensure older stock sells first. As of 2025, some regions even have specific guidelines: for example, China’s 2025 food labeling updates require that even small confectionery items have easily visible production and expiration dates, meaning retailers must not mix up lots. Allergen and sugar substitute notices should also be visible – sugar-free chocolates often contain sugar alcohols or sweeteners, so any required warning (like “Excess consumption may have a laxative effect”) should remain on the package and be legible on shelves. If you’re a retailer, you might also be subject to health inspections: inspectors could check if your store’s ambient temperature is suitable for the foods on sale. Large supermarkets often aim to keep aisle temperatures below ~25 °C (77 °F); boutique chocolate shops often target ~18–20 °C (65–68 °F) in display areas for premium chocolate. Maintaining these conditions not only complies with food quality regulations but also improves customer experience – no one wants to buy a sugar-free chocolate bar only to find it discolored or whitish from heat damage.

[

From the retailer’s perspective, protecting sugar-free chocolate quality is both a compliance issue and a marketing one. Start with your storage areas: when a shipment arrives, check the boxes for any “Keep Refrigerated” or “Store Below X°C” labels. Sugar-free chocolates usually won’t say “refrigerate,” because too cold is also bad, but they will say to keep cool. Ensure your warehouse or back-room storage doesn’t overheat. For instance, if your store is in a place like Arizona or UAE, the loading dock and stockroom can easily top 40 °C (104 °F) – far above safe range. Consider unloading chocolates quickly and moving them into air-conditioned areas. In-store displays: Avoid end-cap displays near sun-facing windows or under hot spotlights. Some retailers use dummy display boxes on shelves and keep the real stock in a cooler area, especially for expensive chocolates, to avoid any degradation. This level of care can prevent having unsellable stock. Regulatory-wise, selling chocolate that has melted and re-solidified (even if it’s technically safe to eat) can hurt your brand and may breach laws against selling food that is not of the nature or quality demanded (in some countries, consumers can claim a refund or report a product that doesn’t meet expected quality due to improper handling). Also keep an eye on labeling: sugar-free products might attract diabetics or other health-conscious buyers, so any required nutritional info and allergen info must be intact. If you do any repackaging (for example, creating gift baskets of sugar-free chocolates), you may need to include the original labels or information – some locales require this to ensure the customer still sees the full info. Employee training is useful here: train your floor staff to recognize signs of chocolate spoilage (bloom or leaking fillings) and remove those items. They should also know not to stack chocolate boxes in hot storerooms or leave them out during store resets. By treating sugar-free chocolate as a product that needs gentle handling – similar to a fine wine or a specialty cheese – retailers adhere to best practices that align with food safety principles. This keeps inspectors happy and customers coming back for more.]

In-store handling guidelines

Retailers can implement simple yet effective practices to maintain compliance and chocolate quality:

Climate Control: Keep store aisles and storage between 18–24 °C (64–75 °F) if possible. Use air conditioning or fans in summer. If a section of your store routinely gets warmer, allocate that space to non-meltable goods and display chocolates in a cooler area.

Avoid Refrigeration Errors: Do not freeze or refrigerate sugar-free chocolate unless absolutely necessary. While a cool environment is good, standard fridge temperature (around 5 °C) can cause condensation when the chocolate is later exposed to room air, leading to sugar bloom. Instead, use temperature-controlled display cabinets specifically designed for chocolates (often set around 15 °C) if you need extra cooling on the sales floor.

Regular Quality Checks: Assign staff to inspect the chocolate section daily in warm seasons. Remove any items showing whitish coating or misshapen bars (signs of bloom or melt) – these should not be sold. Not only does this prevent customer complaints, it also ensures you’re not selling sub-par products that could be considered non-compliant with food quality standards.

case: A high-end retailer in Singapore noticed frequent issues with chocolates (including their imported sugar-free chocolate line) turning white or soft on shelves. In response, they installed small climate-controlled displays that keep chocolates at 18 °C with low humidity. They also adjusted store air conditioning to maintain a max of 24 °C in the confectionery aisle. The impact was immediate: customer complaints about chocolate quality dropped to near zero, and sales of premium sugar-free chocolates rose because the products consistently looked and tasted as intended. This proactive step kept the retailer well within food safety compliance (no more borderline melted products) and enhanced their reputation for quality goods.

(Latest Developments in 2025)

Trends: The cold chain and regulatory landscape for chocolate is continually evolving. In 2025, several new developments are shaping how manufacturers and logistics providers ensure quality. One major trend is the push for enhanced traceability in the food supply chain. For example, the FDA’s FSMA 204 rule on traceability took effect in January 2025 for high-risk foods, and while chocolate isn’t high-risk, this overall trend means stricter record-keeping expectations across the board – companies are adopting digital traceability tools to stay ahead of potential mandates. Sustainability is also now linked with compliance: the European Union’s new deforestation regulation (effective end of 2025) requires chocolate makers selling in the EU to prove their cocoa wasn’t grown on deforested land. This adds a layer of supply-chain oversight that runs parallel to quality control. Meanwhile, governments continue to encourage healthier confections: sugar taxes and advertising restrictions are expanding, indirectly boosting sugar-free chocolate development. As more countries impose sugar levies on sweets, big brands reformulate recipes to reduce sugars, meaning sugar-free and reduced-sugar chocolates are a growth area – and regulators are watching closely to ensure these products are marketed truthfully and handled safely. On the technology front, cold chain logistics is becoming smarter and greener. IoT sensors, blockchain tracking, and AI route optimization are being integrated to not only maintain temperature but also to automatically log compliance data. This modernization is often encouraged (or even funded) by government programs because, according to the FAO, improving cold chain infrastructure can save over 475 million tons of food annually (FAO, 2025). Below is a snapshot of key 2025 developments:

Digital Traceability & FSMA 204: Traceability rules are tightening. In the US, FSMA Section 204 demands faster record access for certain foods, pushing cold chain actors to adopt digital logs and RFID tracking. Many firms aren’t waiting – they’re extending these tools to chocolate shipments to ensure end-to-end visibility, anticipating that regulators worldwide will expect rapid recall capability.

Stricter Quality Regulations: New safety standards came into play, like the EU’s mid-2025 limits on heavy metals in chocolate ingredients (e.g. cadmium, lead). Also, countries like Canada and Australia updated labeling laws – requiring clearer sugar content labels on sweets – which affects sugar-free products by highlighting their sugar substitute content. Manufacturers are responding by investing in cleaner processing and better testing to comply with these strict rules.

Cold Chain Tech & Sustainability: There’s a big push for energy-efficient cold chain solutions. Regulatory incentives in the EU, for instance, encourage low-emission refrigeration units and refrigerants with less global warming potential. Logistics companies are piloting solar-powered cold storage and electric refrigerated trucks. These changes not only meet environmental regulations but also often come with stricter performance monitoring. The result is more reliable temperature control (since new tech comes with advanced sensors) and automatic compliance reports. In parallel, major retailers (Walmart, Carrefour, etc.) have started requiring proof of cold chain integrity from suppliers – effectively making tech adoption a necessity to keep contracts.

[

The market for cold chain and sugar-free chocolate is growing and shifting. Globally, the chocolate confectionery market is still on the rise – projected to grow over 5% annually through 2030 – with the fastest growth in sugar-reduced and premium segments. Consumers are gravitating towards “guilt-free indulgence,” meaning sugar-free chocolates that still taste great are in high demand. This aligns with regulatory trends: as governments fight obesity and diabetes, they support lower-sugar products (through favorable policies or at least by penalizing high-sugar ones). On the cold chain side, emerging markets are investing heavily in infrastructure. For instance, India’s government and private sector are adding refrigerated warehouses and trucks to cut food waste – a move that will also benefit chocolate distribution in hot regions. However, challenges remain: energy costs are high worldwide, making cold chain operations expensive, and not every region has reliable power or facilities yet (as noted, parts of sub-Saharan Africa face logistical hurdles due to limited cold-chain facilities). For businesses, this means you should be strategic: focus on regions where you can ensure cold chain integrity or work with partners to improve it. Overall, companies that invest in quality control and stay ahead of regulations are turning compliance into a competitive advantage. They use their robust cold chain and clean-label credentials as selling points. If you demonstrate that your sugar-free chocolates are not only healthier but also arrive in perfect condition, you win consumer trust. The big picture in 2025 is clear: quality, transparency, and compliance are more important than ever, and they go hand-in-hand in driving success in the sugar-free chocolate market.]

(FAQ)

Q1: Do sugar-free chocolates require refrigeration during shipping?

Sugar-free chocolate doesn’t usually need freezing or standard refrigeration (2–8 °C). However, it does require a controlled cool environment. In transit, aim for about 15–20 °C using insulated packaging or temperature-controlled trucks. The goal is to prevent melting. In hot weather or long international shipments, you should absolutely use cold chain methods (gel packs, reefer containers) to keep chocolates from exceeding ~20 °C. In summary, keep it cool, not frozen – this preserves texture and taste without causing sugar bloom.

Q2: What does “sugar-free” on chocolate labels legally mean?

In most jurisdictions, “sugar-free” means the product contains negligible sugar. For example, the U.S. FDA requires <0.5 grams of sugar per serving for a “sugar-free” claim. The EU has a similar threshold per 100g. This also implies no ingredients were added just for sugar (naturally occurring minimal sugars like in dairy are exempted). Importantly, sugar-free chocolates often use sugar substitutes like maltitol or stevia – regulations require these to be listed, and in some cases (EU) a warning about excessive consumption causing laxative effects if polyols are over a certain amount. So “sugar-free” doesn’t mean calorie-free, but it does mean the chocolate meets strict low-sugar criteria set by food laws.

Q3: How can I prevent chocolate “bloom” during storage?

Chocolate bloom (the white or grayish film that can appear on chocolate) is prevented by maintaining stable temperature and low humidity. Fat bloom happens when chocolate gets warm, melts slightly, then cools – cocoa butter separates and re-solidifies on the surface. Sugar bloom happens when moisture dissolves sugar and then it recrystallizes on the surface. To avoid both: store chocolate at a consistent 12–20 °C in a dry place (humidity under ~50%). Avoid quick temperature swings. For instance, don’t move chocolates directly from a very cold environment to a hot one – condensation could trigger sugar bloom. Using airtight packaging can also help by keeping moisture out. If you keep these conditions steady, your sugar-free chocolate should stay shiny and bloom-free.

Q4: What regulations apply if I export sugar-free chocolate internationally?

When exporting, you must comply with both your country’s rules and the destination country’s regulations. Typically, this includes: having the proper label (translated to the local language if required, with all nutritional info, ingredients, and allergen/sweetener notices meeting local laws), obtaining any necessary health certificates or registrations, and ensuring your shipment meets cold chain requirements during transit (some countries might check port storage conditions). For example, exporting to the EU means your chocolate must meet EU food regulations (no unauthorised additives, within contaminant limits, correct “sugars-free” usage per EU definition). If shipping to countries like China, you need to have your manufacturing facility registered with China’s customs authority and provide documentation; China might also check that the shipment’s temperature was controlled if the product quality was likely to be affected by heat. In all cases, ensure your paperwork (invoices, ingredient lists, test certificates) is in order and consider using a customs broker or consultant for the specific market. Also remember logistics regulations: if sending by air, IATA guidelines for perishable cargo apply (chocolate usually falls under “keep cool” category). Essentially, do your homework for each target market – global food trade has gotten a lot more regulated, but each compliance step you take is rewarded by smoother customs clearance and happy overseas customers.

(Conclusion and Advice)

Point: Navigating cold chain sugar-free chocolate regulations may seem challenging, but focusing on the fundamentals makes it manageable. First, maintain proper conditions from end-to-end – keep chocolates within 12–20 °C and low humidity to preserve quality, whether in the factory, truck, or store. Second, meet all labeling and safety standards – ensure “sugar-free” is truthfully and legally claimed, and follow global food safety protocols (like HACCP and traceability) to avoid compliance issues. Third, invest in monitoring and training – using technology to track temperatures and educating staff at every stage will drastically reduce mistakes. Lastly, remember that these efforts pay off: you’ll deliver a safe, high-quality product that wins customer trust and meets 2025’s higher regulatory expectations. In summary, being proactive about quality and compliance is the recipe for success in the sugar-free chocolate business.

行动建议: To put this into practice, here are some clear next steps for your team:

Perform a Compliance Audit: Review your current operations against the key points in this article. Check your production environment, transport lanes, and store conditions for any gaps (e.g., hotspots in the warehouse, or missing data logs). Identify areas where temperature occasionally slips or documentation is lacking.

Upgrade Processes and Equipment: Based on the audit, implement improvements. This could mean investing in better insulation for shipments, adding a few more temperature sensors, or updating your product labels to meet the latest rules. Even small changes, like using foil-lined boxes for shipping in summer, can yield big quality improvements.

Train and Communicate: Gather your manufacturing staff, drivers, and store managers (or partners) for a quick training session on cold chain handling of chocolate. Ensure everyone knows the importance of keeping sugar-free chocolate within the safe range and what protocols to follow (for instance, what to do if a cooler breaks down). Empower them to speak up if they see a risk (like a pallet of chocolate left on a hot loading dock).

Stay Informed & Engage Experts: Regulations can change, so assign someone to monitor updates from food safety authorities. Consider joining an industry association or subscribing to a cold-chain newsletter so you get heads-up on any new rules or best practices. If you’re ever unsure about compliance, don’t hesitate to consult professionals – whether it’s a food safety auditor or a cold chain specialist. Sometimes an expert eye can save you from costly mistakes.

By following these steps, you’ll create a robust system that not only meets today’s standards but is flexible enough to adapt to tomorrow’s. If you need personalized guidance or advanced solutions to strengthen your cold chain, we’re here to help.

(About Tempk)

Tempk is a leader in cold chain solutions for the food and confectionery industry. We specialize in keeping temperature-sensitive products safe and potent, from factory to finish. With over a decade of expertise in temperature-controlled packaging and logistics, we design systems that maintain the perfect environment for your goods. Our portfolio ranges from high-performance insulated shipping containers and gel packs to real-time temperature monitoring devices that give you full visibility into your supply chain. We pride ourselves on an evidence-based approach – in our projects, we’ve helped clients cut chocolate spoilage by more than 40% by implementing tailored cooling solutions. At Tempk, we marry innovation with compliance: our products meet international quality standards and help you effortlessly align with regulations like FSMA and EU food safety laws. We understand the challenges of sugar-free chocolate logistics and have developed cost-effective, eco-friendly packaging that keeps your treats in peak condition without relying on heavy refrigeration.

Action: Ready to strengthen your cold chain and ensure your sugar-free chocolates arrive flawless? Contact Tempk for professional advice on optimizing your temperature control strategy. We’re here to help you deliver quality and compliance every step of the way. Let’s keep your chocolate sweet and your compliance worries at bay – reach out to our team today for a customized cold chain solution.