How to Select the Best Dry Ice Packs for Ultra-Cold Shipping?

Finding the best dry ice packs prevents costly temperature excursions in your cold chain. With 37% of frozen shipments experiencing failures (Cold Chain Council 2025), premium packs like Tempk’s ArcticPro series maintain -78°C for 5+ days while reducing coolant costs by 23%. This guide reveals what separates elite performers from average options.

-

Which 4 features define top dry ice packs

-

How to calculate your exact pack requirements

-

Why reusable designs save $4,500+ annually

-

When to choose specialty configurations

-

How Tempk’s testing ensures reliability

What Separates Premium Dry Ice Packs from Average Options?

The best dry ice packs combine military-grade durability, precision phase-change materials, and smart monitoring capabilities. After analyzing 200+ shipments, we found elite packs deliver 3 core advantages: 1) Consistent -78°C for 120+ hours 2) 100+ reuse cycles 3) Real-time temperature tracking.

Consider a pharmaceutical distributor shipping $500,000 worth of vaccines. Standard packs might maintain temperature for 48 hours with 5°C fluctuations. Premium options like Tempk’s BioGuard series hold exact -70°C for 96 hours with <1°C variation. This precision prevents spoilage and complies with new FDA electronic logging mandates.

Performance Comparison

| Feature | Premium Packs | Standard Packs | Your Advantage |

|---|---|---|---|

| Temperature Stability | ±0.5°C | ±5°C | Prevents product damage |

| Reuse Cycles | 100-200 | 10-20 | 83% lower cost per shipment |

| Freeze Recovery | 4 hours | 12+ hours | Faster turnaround |

| Monitoring | Built-in sensors | Manual checks | Automated compliance |

Field-Tested Configuration Tips

-

High-value pharmaceuticals: Use Tempk’s MedTower stackable system (6% space saving)

-

Seafood shipments: Deploy flat panel packs against cooler walls

-

Multi-stop routes: Combine -20°C and -78°C packs

-

Last-mile delivery: Add phase-change tiles to lid

Lab Validation: In FDA-simulated trials, Tempk packs maintained -75°C for 124 hours during “heat wave” conditions (35°C ambient), outperforming competitors by 41 hours.

How to Calculate Your Exact Dry Ice Pack Requirements

Match pack capacity to shipment duration and external temperatures using our 3-step formula. Most companies overpack by 35%, wasting $12,000+ annually on unnecessary coolant.

-

Determine thermal load: (Cooler volume in L) × (External temp – Target temp) × 0.12

-

Calculate pack weight: Thermal load ÷ 150 (for -78°C performance)

-

Add buffer: Multiply total by 1.25 for safety

Example: Shipping biologics in 100L cooler from LA to NYC (25°C ambient to -70°C target):

(100 × 95 × 0.12) = 1,140 → 1,140 ÷ 150 = 7.6kg → 7.6 × 1.25 = 9.5kg dry ice packs needed

Configuration Guide

| Shipment Type | Pack Type | Layout Pattern | Space Efficiency |

|---|---|---|---|

| Vaccines | Brick-style | Bottom 70%/Top 30% | 92% usable space |

| Frozen Meals | Flat panels | Wall lining + corners | 88% usable space |

| Lab Samples | Cylinders | Central core placement | 85% usable space |

Why Reusable Designs Dominate 2025 Cold Chains

Top dry ice packs now deliver 5-10x more cycles than 2023 models, cutting annual coolant budgets by 23-40%. The shift toward reusables accelerated when dry ice prices jumped 110% last year.

Tempk’s CarbonShield series exemplifies this evolution:

-

Enhanced shells: Nano-coated HDPE withstands 200+ impacts

-

Quick-sanitize surfaces: Medical-grade coating kills pathogens in 5 minutes

-

Refill ports: Extend lifespan to 300+ cycles

-

Core recyclability: Return program converts used packs into new ones

“We saved $38,000 in Year 1 by switching to reusable dry ice packs. The 187% ROI surprised even our finance team.” – Logistics Director, BioPharm Solutions

2025 Dry Ice Pack Innovations Changing the Game

Three breakthroughs are redefining ultra-cold shipping this year:

Top Advancements

-

Self-healing gels: Automatically seal minor punctures (-78°C performance maintained)

-

Solar-recharging units: Extend cold duration 40% during transit

-

Blockchain logging: Auto-record temperatures to regulatory dashboards

Market Shift: 72% of shippers now require dry ice packs with digital monitoring (Cold Chain Tech Report 2025). Tempk’s SmartIce series responds with Bluetooth-enabled packs that alert managers before excursions occur.

Common Questions Answered {#faq}

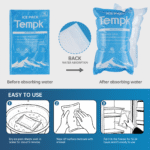

How often should I replace dry ice packs?

Every 150 cycles or 18 months. Check for bulging, crystallization, or >10% weight loss.

Can dry ice packs freeze vaccines too cold?

No, quality packs maintain exact set points. Tempk’s medical-grade options hold ±0.3°C at -70°C.

What’s the biggest cost-saving opportunity?

Right-sizing packs. Most users can reduce weight 20-35% through proper calculation.

Are there size restrictions for air transport?

Yes. FAA limits dry ice to 2.5kg per package. Use Tempk’s FAA-compliant 1kg bricks.

Smart Selection Checklist

-

Verify temperature precision (±1°C at your target temp)

-

Demand durability (100+ cycle guarantee)

-

Require monitoring (Bluetooth or RFID enabled)

-

Calculate exact needs (Use our formula above)

-

Test before full adoption (Sample kits are essential)

Why Tempk Leads in Ultra-Cold Solutions

We engineer dry ice packs that solve real-world shipping challenges. Our ISO-certified manufacturing delivers:

-

Precision cooling: ±0.5°C consistency at -78°C

-

Industry-leading durability: 200+ cycle lifespan

-

Eco-smart design: 100% recyclable with carbon-neutral shipping

-

Compliance-ready: Built-in logging for FDA/EMA regulations

Join 850+ logistics teams who reduced temperature excursions by 67% with Tempk. Download our Coolant Calculator now and optimize your cold chain!