Cold Chain Gelato Smart Packaging: Keep Gelato Perfect?

Last updated: December 16, 2025

Cold chain gelato smart packaging helps you protect texture, prove temperature control, and cut melt complaints. It matters because gelato can lose structure after short warm spikes above −12°C.

cold chain gelato smart packagi…

In real deliveries, the last mile is the danger zone. Many failures happen in the final 20% of the journey.

cold chain gelato smart packagi…

If you want gelato that arrives smooth and scoopable, you need packaging that insulates and packaging that tells the truth.

cold chain gelato smart packagi…

This article will help you:

-

Choose gelato cold chain temperature control targets that protect texture and flavor

cold chain gelato smart packagi…

-

Pick smart packaging sensors for gelato shipping that match your risk and budget

cold chain gelato smart packagi…

-

Build an insulated gelato shipping box with data logger that works end-to-end

cold chain gelato smart packagi…

-

Use a simple decision tool to select the right setup for time and climate

cold chain gelato smart packagi…

-

Validate lanes and scale without guessing, using data you can act on

cold chain gelato smart packagi…

Why does cold chain gelato smart packaging matter more than you think?

Cold chain gelato smart packaging matters because gelato is fragile, and “still frozen” can still mean “ruined.” A short warm-up followed by refreezing can create gritty ice crystals.

That damage is hard to spot at delivery. Customers only discover it when they eat it.

Temperature problems usually happen during handoffs, not inside your freezer. Common risk moments include last-mile delivery, cross-docking, customs holds, and urban multi-stop routes.

cold chain gelato smart packagi…

If you can’t see what happened, you can’t fix it. That’s why “smart” means protection + proof.

cold chain gelato smart packagi…

Gelato cold chain temperature control: where texture damage really happens

You don’t need a hundred theories. You need a simple map of where heat enters your shipment.

| Risk moment | What usually happens | What it causes | What it means for you |

|---|---|---|---|

| Last-mile delay | Box sits in a warm van/lobby | Warm spike + refreeze | “Icy” texture complaints |

| Multiple handoffs | Doors open repeatedly | Short spikes | Hidden damage, hard disputes |

| Oversized shipper | Too much air inside | Faster temp swings | You waste coolant and still lose |

| Inconsistent pack-out | Different staff “styles” | Random results | You can’t compare data |

Practical tips you can use today

-

If your lane is unpredictable: design for stability, not “maximum cold.”

-

If you ship to apartments: treat lobby time as part of transit time.

-

If you only change one thing: standardize pack-out steps before buying more coolant.

cold chain gelato smart packagi…

Real-world case: One team discovered most failures were not “mid-transit.” They were late-day last-mile events. They changed delivery timing and stabilized results.

cold chain gelato smart packagi…

What temperature targets should cold chain gelato smart packaging protect?

Plan around a clear frozen transport window, then track time above your limit. Many operators aim to keep gelato between −14°C and −18°C during transport.

cold chain gelato smart packagi…

Your exact number can vary by recipe and pack size. What matters is consistency.

Shipping is not serving. Gelato may be served warmer, but transport must protect structure through delays. That is why cold chain gelato smart packaging focuses on time + temperature history, not a single “arrival” reading.

cold chain gelato smart packagi…

Set one quality limit you can manage (temperature + time)

If your team needs a simple rule, use this:

-

Pick a temperature limit (your “quality line”).

-

Pick a time allowance (how long above that line is acceptable).

-

Decide the action (replace, refund, review).

cold chain gelato smart packagi…

| Temperature concept | What it means | Why it matters | Simple rule you can apply |

|---|---|---|---|

| Storage target | Best stability zone | Protects texture over time | Design packaging for storage, not serving |

| Softening threshold | Structure loss accelerates | Drives “messy cup” events | Track time above this threshold |

| Refreeze risk | Warm-up + refreeze | Creates grit | Prevent spikes, not just full melts |

Practical tips you can use today

-

Train one message: “We track time above limit, not just arrival temp.”

cold chain gelato smart packagi…

-

Treat seasons like different products: a “summer pack-out” is normal, not optional.

cold chain gelato smart packagi…

-

Make your limit visible: put it on the packing station as a one-page card.

Real-world case: A shop used one shipper year-round. Winter looked fine, summer failed. Data exposed longer warm exposure.

cold chain gelato smart packagi…

Which smart packaging sensors for gelato shipping should you use?

Choose the simplest sensor that your team will actually use—then scale monitoring only on high-risk lanes. Cold chain gelato smart packaging often uses three options: a visual indicator, a single-use digital tag, or a reusable logger.

cold chain gelato smart packagi…

If staff forget to activate or scan a device, it becomes dead weight. Your best sensor is the one that fits your daily workflow.

cold chain gelato smart packagi…

NFC temperature tag for frozen desserts vs indicator vs reusable logger

| Tool type | Best for | What it tells you | What it means for you |

|---|---|---|---|

| Visual threshold indicator | High-volume DTC | Fast pass/fail | Quick triage, low training |

| Single-use digital tag | Mid-to-high value | Time + temp history | Strong evidence without returns |

| Reusable logger | Lane testing, high volume | Deeper curves | Best ROI when you manage returns |

Sensor placement matters. Put the sensor near the product core, close to the cups or tubs. Avoid lid or wall placement.

cold chain gelato smart packagi…

Practical tips you can use today

-

Start with lane learning: use detailed tools for 2–4 weeks, then simplify.

cold chain gelato smart packagi…

-

Use indicators for scale: keep loggers for “hot lanes” only.

cold chain gelato smart packagi…

-

Make data readable: one “breach rule” beats a dashboard nobody checks.

cold chain gelato smart packagi…

Real-world case: One brand placed sensors on shipper walls. Readings looked fine, product arrived soft. Moving sensors next to cups exposed warm air pockets.

cold chain gelato smart packagi…

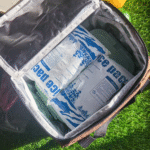

How do you build an insulated gelato shipping box with data logger?

Cold chain gelato smart packaging is a system, not a material. You need insulation, refrigerant, pack-out design, and data working together.

cold chain gelato smart packagi…

If any piece is weak, the lane fails.

Start with lane reality: transit time, ambient heat, and delivery style. Then size insulation and refrigerant for the worst realistic day.

cold chain gelato smart packagi…

PCM vs dry ice: which fits reusable smart shippers for gelato delivery?

| Refrigerant option | Works well when | Risk to manage | What it means for you |

|---|---|---|---|

| PCM packs | Short-to-mid routes | Long delays can break it | Smoother curve, fewer spikes |

| Dry ice | Long routes, high heat | Over-cooling + handling rules | Strong cooling, strict SOP needed |

| Hybrid | Mixed climates/routes | Pack-out complexity | Flexible but needs discipline |

Practical tips you can use today

-

Eliminate air gaps first: fillers beat “more ice” in many lanes.

cold chain gelato smart packagi…

-

Protect the top layer: gelato warms fastest near the lid.

cold chain gelato smart packagi…

-

Standardize pack-out: if steps change, your data won’t compare.

cold chain gelato smart packagi…

Real-world case: Two packers used different styles on the same lane. Data looked random. A photo checklist made results predictable and fixable.

cold chain gelato smart packagi…

How can cold chain gelato smart packaging reduce melt claims fast?

Cold chain gelato smart packaging reduces claims by turning uncertainty into evidence and prevention. Without data, you argue with opinions. With data, you fix patterns and make decisions quickly.

cold chain gelato smart packagi…

Most claims come from repeatable problems: late delivery, seasonal under-packing, slow handoff, or weak seals. Smart packaging exposes those patterns early.

cold chain gelato smart packagi…

Build a simple “quality guardrail” policy

| Guardrail element | What you define | Why it matters | Practical example |

|---|---|---|---|

| Temperature limit | Your max temp | Aligns quality + decisions | “Above X°C is high risk” |

| Time allowance | How long above limit | Avoids overreacting | “Up to Y minutes total” |

| Action rules | Replace/refund/review | Speeds support | “Replace if breach + photo” |

Practical tips you can use today

-

Review lanes weekly: prevention beats one-off refunds.

cold chain gelato smart packagi…

-

Segment lanes: protect repeat offenders first.

cold chain gelato smart packagi…

-

Align promises with ops: don’t market what your lane can’t deliver reliably.

cold chain gelato smart packagi…

Real-world case: Melt claims clustered in apartment package rooms. Adding “bring inside immediately” labeling and earlier delivery windows reduced warm exposure.

cold chain gelato smart packagi…

How do you validate cold chain gelato smart packaging lanes in 2025?

Validate before you scale. Cold chain gelato smart packaging needs proof under real lane conditions, not hope.

cold chain gelato smart packagi…

Treat validation like a monthly health check. Carriers and weather change fast.

cold chain gelato smart packagi…

If you want a recognized structure, many teams align parcel thermal thinking with profiles such as ISTA 7E. (Mentioned in your draft.)

cold chain gelato smart packagi…

Monthly lane test plan (5–10 shipments per lane type)

A practical start is 5–10 test shipments per lane type, across different days.

cold chain gelato smart packagi…

| Test step | What to do | What you learn | What it means for you |

|---|---|---|---|

| Pick 3 lane types | Local, regional, long | Risk profiles differ | One pack-out won’t fit all |

| Ship with loggers | Sample each lane | Real temp curves | Find the “weak hour” |

| Review outcomes | Compare to limit | Pass/fail margin | Improve before peak season |

Practical tips you can use today

-

Test during heat waves and peaks: that’s when failures happen.

cold chain gelato smart packagi…

-

Keep a “gold standard” pack-out: compare every change against it.

cold chain gelato smart packagi…

-

Log packing time at room temp: minutes matter more than you think.

cold chain gelato smart packagi…

Real-world case: A brand validated in spring and assumed summer would match. It didn’t. Monthly tests led to seasonal refrigerant adjustments and fewer refunds.

cold chain gelato smart packagi…

Decision tool: Which cold chain gelato smart packaging setup fits your lane?

Cold chain gelato smart packaging should match lane reality, not hopes.

cold chain gelato smart packagi…

Use this quick self-check. Total your score, then choose a starting setup.

Quick self-assessment (score yourself)

-

Delivery time is 0–12 hours (1 point)

cold chain gelato smart packagi…

-

Delivery time is 12–36 hours (2 points)

cold chain gelato smart packagi…

-

Delivery time is 36–72 hours (3 points)

cold chain gelato smart packagi…

-

Typical summer ambient is mild (1 point)

cold chain gelato smart packagi…

-

Typical summer ambient is hot (2 points)

cold chain gelato smart packagi…

-

Last-mile delivery is unpredictable (2 points)

cold chain gelato smart packagi…

-

Order value is high (2 points)

cold chain gelato smart packagi…

-

You ship 100+ orders/week (2 points)

cold chain gelato smart packagi…

-

You need proof for compliance or partners (2 points)

cold chain gelato smart packagi…

Score guide:

-

3–5: Basic smart layer

cold chain gelato smart packagi…

-

6–9: Standard smart system

cold chain gelato smart packagi…

-

10+: Advanced smart system

cold chain gelato smart packagi…

| Setup level | Packaging + refrigerant | Smart layer | Best for you if… |

|---|---|---|---|

| Basic smart layer | Solid insulation + consistent pack-out | Threshold indicator | You need fast scale, low complexity

cold chain gelato smart packagi… |

| Standard smart system | Lane-tuned insulation + PCM or hybrid | Single-use digital tag | You want prevention + clear evidence

cold chain gelato smart packagi… |

| Advanced smart system | High-performance shipper + strict SOP | Reusable logger + alerts | You manage high volumes or high-value lanes

cold chain gelato smart packagi… |

2025 latest developments and trends in cold chain gelato smart packaging

In 2025, cold chain gelato smart packaging is shifting toward data-driven optimization and sustainability. Packaging is no longer just protection. It is intelligence.

cold chain gelato smart packagi…

Latest progress at a glance

-

Smarter indicators that show cumulative exposure

cold chain gelato smart packagi…

-

Reusable smart systems that reduce long-term cost

cold chain gelato smart packagi…

-

Predictive analytics to optimize routes and reduce exceptions

cold chain gelato smart packagi…

Market insight you can apply

Premium frozen dessert expectations are rising. “Almost fine” is not fine anymore. When quality transparency influences buying decisions, proof becomes part of the product experience.

Frequently Asked Questions

Q1: What temperature should gelato be kept at during transport?

Many operators target −14°C to −18°C during transport, then validate on real lanes.

cold chain gelato smart packagi…

Q2: Is cold chain gelato smart packaging necessary for short deliveries?

Often yes. Urban traffic and handoffs create unpredictable heat exposure.

cold chain gelato smart packagi…

Q3: Where should I place the sensor inside the shipper?

Place it near the product core, close to gelato cups or tubs. Avoid lid or wall placement.

cold chain gelato smart packagi…

Q4: How many lane tests do I need before scaling?

A practical start is 5–10 test shipments per lane type, across different days.

cold chain gelato smart packagi…

Q5: How do I choose the right configuration quickly?

Start with your real conditions: duration, ambient exposure, handling frequency, and monitoring needs.

cold chain gelato smart packagi…

Summary and recommendations

Cold chain gelato smart packaging protects gelato by combining insulation, refrigerant, standardized pack-out, and easy temperature evidence.

cold chain gelato smart packagi…

The fastest wins come from eliminating air gaps, protecting the top layer, and using sensors your team will actually use.

When you track time above your chosen limit, you can find weak lanes and fix them systematically.

A simple next-step plan:

-

Define one quality limit (temperature + time).

-

Run lane tests for 2–4 weeks with tags or loggers.

-

Fix the top two failure patterns (often last-mile timing and pack-out consistency).

-

Keep smart tools on high-risk lanes and standardize everywhere else.

About Tempk

At Tempk, we build cold-chain packaging systems designed for real delivery conditions. We focus on cold chain gelato smart packaging that is practical to pack, stable across seasons, and easy to validate with simple data workflows.

cold chain gelato smart packagi…

Our approach combines insulation performance, pack-out standardization, and smart monitoring options—so your team spends less time guessing and more time delivering consistent gelato quality.

cold chain gelato smart packagi…

Call to action: If you want to reduce melt claims and standardize your gelato shipping lanes, talk with us about a lane-tested smart packaging setup you can scale with confidence.