How to Choose a Dry Ice Bag With Handle in 2025

If you ship frozen goods, the right dry ice bag with handle protects product, people, and profit. It must hold −78.5 °C dry ice safely, vent CO₂, and meet air/ground rules like UN1845 marking. Below is a practical, SEO‑friendly playbook to pick, pack, and label a dry ice bag with handle for reliable 24–72‑hour performance. ehs.washington.edu+1

-

Pick the best dry ice bag with handle for route, weight, and compliance (e.g., IATA air rules).

-

Build pack‑outs that keep −20 °C or below for 24–72 hours with proper venting and insulation.

-

Label and handle safely to minimize CO₂ buildup and frostbite risks in any dry ice bag with handle.

-

Balance cost and sustainability using reusable liners and return loops.

-

Track 2025 trends in materials, VIP shippers, and reusable systems that influence your choice.

What is a dry ice bag with handle, and which design fits your route?

Short answer: A dry ice bag with handle is a flexible, hand‑carry pouch engineered for dry ice—built to vent CO₂ gas, resist brittle cracking at cryogenic temperatures, and carry a defined load. Choose design by route time, carrier rules, and ergonomics. Typical designs include die‑cut handles, stitched straps, or reinforced loop handles rated for 8–20 kg. OSHA

Longer explanation: Think of a dry ice bag with handle as a soft‑sided “mini shipper.” Films (PE / metallized PET) slow heat gain; vents prevent pressure; and the handle spreads weight so staff can move safely. If you’re flying, IATA requires UN1845 marking and net dry ice weight; if you’re trucking or ocean‑freighting, DOT/IMDG have their own marking and stowage rules. For last‑mile, a compact insulated dry ice bag with handle reduces porch time risks and simplifies hand‑offs. IATA+1

Handle types and load ratings for a dry ice bag with handle

Stitched webbing handles carry more weight and stay flexible when cold. Die‑cut handles are compact but can bite into hands at higher loads. Loop handles allow two‑hand carry—useful for 10 kg+ dry ice plus product. Many cooler‑style bags cite 30–36″ strap lengths to improve comfort during facility moves. Match handle to load, distance, and staff PPE. Custom Earth Promos

| Handle Option (bag type) | Typical Load | Recommended Use | What it means for you |

|---|---|---|---|

| Die‑cut (punched) dry ice bag with handle | ≤8 kg | Short indoor transfers | Slim profile; cheap; tighter hand grip |

| Sewn webbing dry ice bag with handle | 8–15 kg | Route picks, dock moves | Better comfort; fewer hand hot‑spots |

| Dual loop dry ice bag with handle | 12–20 kg | Long corridors, elevator rides | Two‑hand carry, safer with PPE and stairs |

Practical tips

-

E‑commerce frozen boxes: Use a small dry ice bag with handle as an inner liner to reduce fog “puff” when opening.

-

Hospital couriers: Pick vented flap designs so CO₂ escapes during elevator trips.

-

Seafood exporters: Prefer loop‑handle models for two‑hand lifts over wet floors; pair with anti‑slip mats.

Real case: A lab switched to a dual‑loop dry ice bag with handle for 1.5 km campus transfers. Reported fewer hand injuries and steadier loads; CO₂ vents prevented bag ballooning in warm hallways.

How do you safely pack a dry ice bag with handle for 24–72 hours?

Core answer: Pre‑freeze product, pre‑chill packaging, add adequate dry ice, and never seal gas‑tight. Label UN1845 and net dry ice weight for air; ensure ventilation and PPE. This prevents frostbite and CO₂ buildup, two leading incident causes with any dry ice bag with handle. ehs.washington.edu+1

Why it works: Dry ice sublimates (solid → gas) and cools as it does. In a well‑insulated dry ice bag with handle, expect 5–10 lb to vanish per day. Plan quantity by route time and ambient temps; pack dry ice above product so cold gas sinks through payload. Never wrap dry ice in plastic—vent it. safety.rochester.edu+1

Pack‑out recipes for a dry ice bag with handle

Labeling & compliance:

-

Air (IATA): Mark “UN1845 DRY ICE (Carbon dioxide, solid)” and net weight; follow the current acceptance checklist (no Shipper’s Declaration when shipped with non‑dangerous goods, but acceptance checks are required). IATA

-

Ground (DOT 49 CFR 173.217): Provide required markings; ensure packaging allows CO₂ to vent. Ocean stowage has “do not stow below decks” rules for some packagings. eCFR+1

-

Food shipments: USDA/FSIS mail‑order guidance highlights sturdy boxes, cold sources, and safe end‑user handling. Pair your dry ice bag with handle with clear customer notes. Food Safety and Inspection Service

What size dry ice bag with handle do you need for weight and volume?

Rule of thumb: Pick a dry ice bag with handle that supports 2–3× the payload mass when you add dry ice and insulation. If the product is 3 kg and dry ice is 6 kg, size for 9–10 kg and verify handle stitching and seam strength. Use pellets for tight spaces; use blocks for slower sublimation. Dry ice sits at −109 °F; handle with insulated gloves. ehs.washington.edu

Sizing checklist—choose your dry ice bag with handle:

-

Duration: 24, 48, or 72 h route? Longer → thicker insulation, more headspace for gas.

-

Ambient: >32 °C? Consider VIP inserts around your dry ice bag with handle for stability. 360 Research Reports

-

Ergonomics: If >10 kg total, use dual loop handles and two‑hand carry.

-

Accessibility: Include a tear‑open feature so receivers don’t stab bags and puncture liners.

Material and insulation options for a dry ice bag with handle

-

Metallized film liner: Reflects heat; light; economical.

-

PE/LLDPE co‑extrusions: Tough against puncture at low temps.

-

VIP panels (optional): Add 20–40% runtime in hot lanes; cost more but reduce dry ice mass. 360 Research Reports

| Feature | Option A | Option B | What it means for you |

|---|---|---|---|

| Insulation | Metallized bubble | VIP insert + bubble | VIPs extend hold time; use less dry ice |

| Handle | Die‑cut | Sewn webbing | Webbing reduces hand strain at high loads |

| Vent path | Grommet flap | Perforated fold | Prevents pressure and bag ballooning |

Compliance checklist for a dry ice bag with handle (air & ground)

Essentials for any dry ice bag with handle pack‑out:

-

Markings: UN1845 + net dry ice weight (kg). Air operators use acceptance checklists; missing weight marks is a common rejection reason. IATA

-

Venting: Packaging must allow CO₂ to escape. Never seal a dry ice bag with handle in an airtight outer. Carriers warn against wrapping or fully sealing dry ice. UPS

-

Storage & stowage: Don’t keep dry ice in confined spaces; ensure ventilation during holding and transport. OSHA

-

Ground DOT: Follow 49 CFR 173.217 for transport and markings; maritime has specific warnings about below‑deck stowage. eCFR

Quick self‑audit (2 minutes):

Is the dry ice bag with handle vented? 2) Is UN1845 + net kg on the outer? 3) Is PPE available (gloves/eye protection)? 4) Is there a written handover note for the receiver?

How much dry ice should a dry ice bag with handle carry?

Planning math: In typical coolers, dry ice sublimates ~5–10 lb per 24 h. For 48 h, budget 10–20 lb depending on ambient and insulation. Blocks last longer than pellets; pellets give better contact. Always build a buffer for delays. safety.rochester.edu

Ambient matters: Hot routes (>30 °C) accelerate sublimation. Consider a VIP insert or add 20–30% extra dry ice in your dry ice bag with handle in summer. Place dry ice above product; CO₂ is heavier than air and sinks to envelop the payload. 360 Research Reports

Example calculations for a dry ice bag with handle

| Scenario | Payload | Duration | Ambient | Suggested Dry Ice | Why |

|---|---|---|---|---|---|

| Frozen desserts, urban | 3 kg | 24 h | 20 °C | 3–4 kg | Pellets; more surface for fast pull‑down |

| Seafood, 2‑leg flight | 5 kg | 48 h | 25 °C | 7–9 kg | Blocks on top; pellets around sides |

| Biomed, hot lane | 2 kg | 72 h | 32 °C | 9–10 kg | Add VIP panels around dry ice bag with handle |

Safety: PPE, ventilation, and end‑user guidance for your dry ice bag with handle

Bottom line: Dry ice can burn skin and displace oxygen. Use gloves and eye protection; ventilate rooms and vehicles; include a receiver note in every dry ice bag with handle shipment (how to let remaining dry ice evaporate safely). ehs.washington.edu+1

-

PPE: Use loose‑fitting cryo gloves and eye protection. Avoid sealed spaces and walk‑ins without ventilation. OSHA

-

Receiver notice: “Contains dry ice; do not touch with bare hands; allow to evaporate in a ventilated area; keep away from kids and pets.” (USDA/FSIS recommends cold sources and safe handling for mail‑order foods.) Food Safety and Inspection Service

-

Hazard status: Dry ice isn’t an OSHA “Hazardous Substance,” but it is a Dangerous Good for transport, so transport rules apply. Cornell EHS

Cost & sustainability: the business case for your dry ice bag with handle

Where cost lives: Material (bag + ice), labor (conditioning), surcharges (hazmat), and spoilage risk. Reusable liners and VIP inserts can cut dry ice mass and reduce damages. In 2025, cold‑chain packaging is growing fast; reusable ecosystems are scaling. Grand View Research+1

Market pulse:

-

U.S. cold chain packaging topped ~$8 B in 2024, with double‑digit growth through 2030. Grand View Research

-

Reusable cold‑chain packaging forecast: ~$5 B+ in 2025, nearly $9 B by 2034. Towards Packaging

-

VIP shipper adoption is rising to extend hold times with less dry ice. 360 Research Reports

ROI quick check: If VIPs trim 25% dry ice from a 10 kg pack‑out (2.5 kg saved per box) at $2.50/kg, you save ~$6.25 per shipment—often offsetting the bag or panel premium within a few cycles.

2025 trends shaping the dry ice bag with handle

Trend snapshot (2025): Airlines use updated acceptance checklists for dry ice. VIP panels expand into parcel flows. Reusable programs scale. Dry ice market growth continues as frozen e‑grocery and biologics rise. All impact how you spec a dry ice bag with handle. IATA+2360 Research Reports+2

Latest advances at a glance

-

Carrier acceptance tools: 2025 IATA checklist streamlines checks when no Shipper’s Declaration is required—reduce rejections with correct UN1845 weight marking on your dry ice bag with handle. IATA

-

VIP + soft‑bag hybrids: Slim VIP tiles around a dry ice bag with handle boost duration in hot lanes without extra weight. 360 Research Reports

-

Reusable loops: Operators add collection bins and reverse logistics for coolers and dry ice bag with handle liners to cut waste and cost. Towards Packaging

Market insight: Dry ice demand keeps rising with frozen foods, meal kits, and biopharma lanes. Analysts project global dry ice growth from ~$1.66 B in 2025 toward ~$2.7 B by 2032, validating long‑term availability planning for your dry ice bag with handle program. Fortune Business Insights

Mini decision tool: which dry ice bag with handle should you buy?

-

Route time? 24 h / 48 h / 72 h+

-

Ambient peak? <25 °C / 25–32 °C / >32 °C

-

Payload mass? ≤3 kg / 3–6 kg / >6 kg

-

Carry style? Single‑hand (short) / Two‑hand (long corridor)

-

Air or ground? Air → IATA weight marking required; Ground → DOT rules apply. IATA+1

Output—your starter spec:

-

If 48 h, 25–32 °C, 4 kg payload, air → Metallized dry ice bag with handle, sewn webbing, 6–8 kg dry ice, vented flap, VIP insert, UN1845 label with net kg.

-

If 24 h, <25 °C, 2 kg, ground → Die‑cut dry ice bag with handle, 3–4 kg pellets, simple vent grommet, DOT marking.

Frequently Asked Questions

Q1: How cold is a dry ice bag with handle in use?

Dry ice sits near −109 °F (−78.5 °C); the bag doesn’t set the temperature, it slows heat gain and safely vents gas. Always wear PPE and ventilate. ehs.washington.edu

Q2: Do I need special labels for a dry ice bag with handle on airplanes?

Yes. Mark UN1845 and the net dry ice weight on the outer package; use the carrier’s acceptance checklist to avoid rejections. IATA

Q3: Can I fully seal a dry ice bag with handle to trap cold?

No. Packaging must vent CO₂; never wrap or tape an airtight seal around dry ice. UPS

Q4: How much dry ice should I load into a dry ice bag with handle for 48 hours?

Plan ~10–20 lb total depending on ambient, insulation, and payload. Blocks last longer; pellets fill gaps. Add a buffer for delays. safety.rochester.edu

Q5: Is a dry ice bag with handle OK for food shipments?

Yes, if you use a sturdy container, adequate cold source, and include safe‑handling instructions for the receiver. Food Safety and Inspection Service

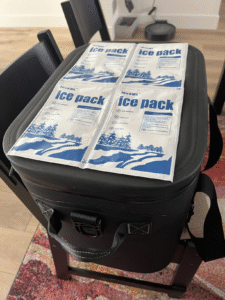

Q6: Where can I learn when to use gel packs instead of dry ice?

See our head‑to‑head comparison of dry ice and gel packs for use cases and pros/cons.

Dry Ice Bag vs Gel Packs

Summary & recommendations

-

A dry ice bag with handle must vent, insulate, and carry—safely moving gas and weight while meeting UN1845 labeling.

-

Size your dry ice bag with handle for 2–3× payload mass to cover dry ice and accessories.

-

For 24–72 h, plan 5–10 lb/day sublimation, pack dry ice above product, and build a buffer.

-

Use PPE, ventilate, and include a receiver note in every dry ice bag with handle shipment.

-

Consider VIP panels and reusable loops to cut ice mass and total cost.

Action plan:

-

Define route time and ambient. 2) Choose a vented dry ice bag with handle with the right handle design. 3) Build a labeled pack‑out (UN1845 + net kg). 4) Pilot‑test with a temp logger. 5) Scale with reusable assets, and review results quarterly. Need a template? Ask our team for a lane‑specific pack‑out for your dry ice bag with handle.

About Tempk

We build practical cold‑chain solutions that ship frozen and chilled products safely—bags, liners, VIP‑ready shippers, and monitoring. Our engineers optimize pack‑outs so your dry ice bag with handle uses less ice and stays compliant across carriers. We focus on measurable gains: longer hold times and fewer rejections—backed by 10+ years of route data.

Ready to reduce dry ice and improve compliance?

→ Contact Tempk for a free 15‑minute pack‑out review.