Dry Ice Bag with Valve: How to Choose, Pack, and Comply

If you ship frozen payloads, a dry ice bag with valve keeps gas venting safe while protecting your product. Within the first mile it prevents pressure build-up, supports IATA PI 954 compliance, and helps you pass 2025 carrier checks. Plan 5–10 lb dry ice per 24 h and mark UN1845 with net kg on the outer box so acceptance goes smoothly.

-

Sizing fast: plan ice mass for 24–72 h using a simple estimator and lane factors.

-

Safe pack-out: step-by-step setup so your dry ice bag with valve vents freely and passes audits.

-

Valve choices: one-way valve vs. ePTFE membrane and when each wins on real routes.

-

Regulatory must-haves: PI 954 venting, UN1845 marks, and “not airtight” rules demystified.

-

When not to use dry ice: 2–8 °C lanes and safer alternatives.

Which dry ice bag with valve should you choose?

Pick a bag that vents CO₂ by design, tolerates −78.5 °C, and fits your shipper so the valve is never blocked. This aligns your inner packaging with PI 954’s requirement that the package must permit gas release while staying non-airtight. Validate the bag with your specific shipper geometry and lane.

Why it matters to you: the right dry ice bag with valve controls back-diffusion of humid air (fewer clumps), reduces ballooning risk, and supports clean carrier acceptance when paired with a vent-permitted outer box and correct labels.

Valve vs. membrane—what’s best for your route?

One-way mechanical valve gives high CO₂ flow and minimal backflow; orientation matters. ePTFE membrane vents equalize pressure continuously with no moving parts and resist splash—handy in humid legs or multi-ascents. For both, confirm cold-rated materials and airflow capacity at your worst-case sublimation rate.

| Option (vent type) | How it works | Typical strength | What it means for you |

|---|---|---|---|

| One-way valve | Opens at low cracking pressure to pass gas | High CO₂ flow, low O₂/H₂O ingress | Great for high loads; keep the valve path unobstructed |

| ePTFE membrane | Microporous film equalizes pressure | No moving parts; splash resistant | Stable with vibration/altitude; verify low-temp rating |

| Perforated film | Small holes in bag | Simple, low cost | Not moisture-blocking; still requires non-airtight outer box |

Practical tips for buyers

-

Ask for airflow data at cold: request SCFH at −20 °C or colder.

-

Check film toughness: low-temp ductility avoids cracks at −80 °C.

-

Fit before you buy: ensure the valve faces free air volume and won’t be taped over.

Real-world win: A biotech shipping 48 h across two hubs switched to a dry ice bag with valve and increased mass from 20 lb to 24 lb. Excursions dropped to zero in six weeks, and acceptance delays disappeared once UN1845/net-kg marks were standardized.

How do you pack a dry ice bag with valve so carriers accept it?

Short answer: Keep the system vented, label correctly, and document. Mark the outer carton on two sides with “Dry Ice/Carbon dioxide, solid (UN1845)” and net kg, apply Class 9, and never make the package airtight—even with a valve inside.

Pack-out (auditor-friendly):

-

Pre-stage product at labeled temperature; confirm shipper vents and valve path are open.

-

Place logger near the payload core (not inside pellets).

-

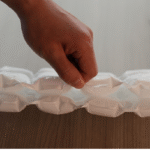

Load dry ice into the dry ice bag with valve; close with a non-airtight tie so gas exits via the valve.

-

Layer per validation with spacers to avoid direct glass/vial contact; keep a standoff.

-

Close & label: UN1845 + net kg + Class 9; match airway bill; record time, lot, logger ID.

Labeling rules—made simple

-

Proper shipping name & UN: “Dry Ice” or “Carbon dioxide, solid”, UN1845.

-

Net quantity: state net kg of dry ice on the box.

-

Venting: package must permit release of CO₂; do not tape over valves or box vents.

How much dry ice should a dry ice bag with valve hold?

Plan 5–10 lb per 24 h in a well-insulated shipper; use the high end for hot ramps or frequent openings. For aircraft small-load planning, a ~2%/h sublimation basis is a conservative assumption. Add ~20% margin for handoffs.

| Scenario | Planned hours | Start calc (lb/24 h) | Add margin | What to pack |

|---|---|---|---|---|

| Express lane | 24 | 10 | +20% | ~12 lb |

| 48 h, 2 handoffs | 48 | 20 | +20% | ~24 lb |

| Warm tarmac, long route | 72 | 30 | +20–30% | 36–39 lb |

Safety: does a dry ice bag with valve reduce exposure risk?

It helps prevent pressure build-up, but space ventilation is still essential. Follow OSHA PEL 5,000 ppm (8-h TWA) and NIOSH STEL 30,000 ppm; train staff and consider CO₂ monitors in staging areas and vehicles.

When not to use a dry ice bag with valve—and what to use instead

If the label states 2–8 °C (not frozen), do not use dry ice. Use conditioned PCM bricks/ice packs and a validated 2–8 °C shipper per GDP/USP guidance. For vehicles or spaces with poor ventilation, consider −20 °C/−50 °C PCMs instead of dry ice.

2025 trends in dry ice bag with valve technology and practice

What’s new this year: updated small-load sublimation data helps right-size ice and airflow; ePTFE vents are tuned for recovery after liquid contact; shippers are cutting waste with CO₂-recovered sources and loggers + calculators instead of “over-icing.” Expect RFQs to ask for valve airflow at −20 °C, cracking pressure, OTR for the film, and PI 954 SOP proof.

FAQs

Is a dry ice bag with valve mandatory for air shipments?

Not strictly. PI 954 requires packages to permit CO₂ release and avoid pressure build-up; a valved bag is one compliant way when the system isn’t airtight.

How much dry ice per day should I plan?

Start with 5–10 lb per 24 h in a typical insulated shipper, then add ~20% for hot ramps or multiple handoffs.

What labels are required?

Mark “Dry Ice/Carbon dioxide, solid (UN1845)” and the net kg on two opposite sides; include the Class 9 label for air.

Does a valve remove CO₂ exposure risks?

No. It relieves pressure, but you still need ventilation to control airborne CO₂ levels.

Can I use a valved bag for 2–8 °C vaccines?

No—use PCMs and a validated 2–8 °C shipper; dry ice can freeze and damage those products.

Summary & recommendations

Bottom line: A dry ice bag with valve gives controlled venting, cleaner moisture management, and smooth acceptance—if you size ice correctly, keep the system non-airtight, and label UN1845 + net kg. Train teams on OSHA/NIOSH limits and document PI 954 compliance in your SOP.

Next steps (do-now plan):

-

Audit lanes & handoffs; 2) Validate a valved-bag pack-out with a logger; 3) Standardize pre-printed UN1845/net-kg labels; 4) Train quarterly on CO₂ safety; 5) Optimize mass with route data.

About Tempk

We help pharma, biotech, and food shippers move temperature-sensitive products with audited reliability. Our team designs validated pack-outs, supplies dry ice bag with valve kits rated for cold service, and builds lane-specific SOPs that pass regulatory and carrier checks. Clients cut excursions and acceptance delays while reducing dry ice waste.

CTA: Need a lane-specific pack-out and sizing table? Request a 30-minute consult and get a dry-ice mass plan, label set, and a one-page SOP your team can train in 15 minutes.