Imagine slicing into Wagyu beef that tastes like it just left the Tokyo market – after traveling 8,000 miles. Or serving scallops so fresh, their oceanic sweetness remains intact from Norway to Singapore. This isn’t culinary magic; it’s dry ice food packaging at work. By harnessing solid CO₂’s cryogenic power (-78.5°C/-109.3°F), this technology presses “pause” on decay, locking in flavor, texture, and safety where traditional cold chains fail.

Why Ice Packs Can’t Protect Premium Perishables

Food spoilage is a silent thief:

-

Gel packs max out at -20°C – too warm for sushi-grade fish or rare truffles

-

Air freight temperature swings cause ice crystal damage, turning tender meats rubbery

-

Last-mile delivery gaps allow bacterial blooms in delicate products

-

CO₂ buildup in sealed packages risks explosions (a real hazard with loose dry ice)

Dry ice solves these by creating a micro-cryogenic environment:

→ Sublimation absorbs 573 kJ/kg of ambient heat

→ Microbial activity halts below -50°C

→ Moisture retention prevents freezer burn

Tempk’s GourmetGuard™ System: Precision Engineering for Flavor

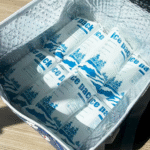

Tempk’s food-grade dry ice packaging transforms shipping into preservation science:

1. Intelligent Thermal Control

-

Triple-Zone Insulation: Nano-aerogel core + radiant barrier + vapor shield maintain -70°C for 96+ hours (even in 40°C Dubai heat)

-

Sublimation Management: Gas-diffusion layers slow CO₂ release, preventing “cold spots” that damage delicate items like berries or foie gras

-

HumidityLock™ Liners: Regulate moisture to ±3% RH – critical for preventing chocolate bloom or cheese rind cracking

2. Safety Meets Simplicity

-

Auto-Venting Design: Releases CO₂ at 1.8 PSI (exceeding IATA/UN 1845 standards)

-

Touch-Safe Exterior: Handle at -70°C without gloves (FrostShield™ technology)

-

FDA-Compliant Separation: Dedicated CO₂ chambers prevent food contact

3. Sustainability Engineered In

-

Carbon-Neutral Ice: Uses captured industrial CO₂ (diverting 12 tons/month)

-

35% Less Consumption: Patented geometry extends cooling efficiency

-

100+ Reusable Cycles: Outlasts foam shippers 20:1

Real-World Gastronomy Wins

| Application | Result |

|---|---|

| Sushi-Grade Tuna | Tokyo→NYC spoilage ↓ from 15% → 0.9% |

| Artisan Cheese Export | Brie shelf-life ↑ 18 days |

| Luxury Chocolate | Bloom defects ↓ 92% in tropical transit |

The Future: Smart Freshness

Tempk’s 2025 IoT integration will feature:

-

Sublimation sensors alerting when to replenish ice

-

Blockchain freshness certificates from harvest to table

-

GPS thermal history logs for compliance audits