Dry Ice Packaging 2025: The Definitive Guide to Shipping Frozen Goods, Flying with 5.5 lb & Slashing Costs

This expert playbook fuses the strongest concepts from three in‑depth articles on package engineering, TSA‑approved air travel, and flexible dry‑ice sheets—all rewritten and cross‑linked to hit Google’s 2025 EEAT, Helpful Content and Page Experience signals.

-

Why Dry Ice Still Rules Cold Chain 2025

-

Compliance at a Glance: Ground, Air & Cooler Sheets

-

Designing the Perfect Dry‑Ice Package

-

Flying Frozen: TSA/FAA 5‑Step Checklist

-

Dry‑Ice Pack Sheets: Flexible Cooling Math

-

Safety & 2025 Label Updates

-

Cost‑Saving & Sustainability Hacks

-

2025‑2030 Market & Tech Outlook

-

FAQ

-

Summary & Action Plan

1. Why Dry Ice Still Rules Cold Chain 2025

Dry ice sublimes at –78 °C, absorbing 571 kJ kg‑¹—the highest energy density of any food‑safe refrigerant. Shippers that pair the right package, coolant form & regulatory label cut temperature excursions by up to 63 % and freight weight 18–40 %.

2. Compliance Matrix

| Mode / Topic | Key Limit | Must‑Have Label | Ideal Coolant | 2025 Fee* | Best Use |

|---|---|---|---|---|---|

| Ground parcel | None (Class 9 rules) | “UN 1845 DRY ICE” + weight | Blocks / Sheets | FedEx/UPS $8 | Meal kits, frozen food |

| Passenger air | ≤ 5.5 lb (2.5 kg) | Same + airline OK | 1 lb sheets or mini‑blocks | None | Gifts, biologics carry‑on |

| Cargo air | > 5.5 lb (Class 9 DG) | Shipper’s Dec. + Class 9 | Blocks + sheets | $8 + DG fee | Bulk vaccine export |

| Cooler insert | Vent + CO₂ warning | “Releases CO₂” (FDA) | Sheets | — | Last‑mile frozen delivery |

*FedEx & UPS surcharge rose to USD 8.00 on 1 Jan 2025.

3. Designing the Perfect Dry‑Ice Package

3.1 Core Stack

| Layer | 2025 Spec | Why It Matters |

|---|---|---|

| Outer shipper | 275 lb burst corrugate, moisture‑barrier | Survives 6‑foot drop |

| Insulation | EPS 1.5 in or VIP R‑25 | VIP cuts dry‑ice load ≈ 40 % |

| Coolant | Pellets / Sheets / Block hybrid | Balance weight vs hold‑time |

| Smart label | NFC + QR temperature logger | Meets FDA FSMA two‑year record rule |

| Venting | 6 mm one‑way valve | Prevents 50 psi over‑pressure |

3.2 Universal Sizing Formula

Dry‑Ice (lb) = Product (lb) × 0.6 × Transit (days) × Temp‐Factor

Temp‑Factor = 1.2 above 30 °C; 0.8 below 10 °C.

Example – 20 lb seafood, 2‑day ground, 32 °C ambient

20 × 0.6 × 2 × 1.2 ≈ 29 lb dry ice → save 12 lb using VIP.

4. Flying Frozen: TSA / FAA 5‑Step Checklist

-

Weigh dry ice ≤ 5.5 lb per passenger.

-

Vent container—two 6 mm holes or valve.

-

Label “DRY ICE / UN 1845 – X lb” on two sides ≥ 12 mm high.

-

Declare at airline counter; keep e‑approval email.

-

Gloves & eye‑pro for pack‑out; CO₂ burns skin < –60 °C.

Pro‑tip: Two travellers = 11 lb allowance; split the load to double capacity without cargo paperwork.

5. Dry‑Ice Pack Sheets: Flexible Cooling Math

| Spec (2025) | Typical Range | Impact |

|---|---|---|

| Sheet size | 13 × 14 in → 18 × 20 in | Lines any cooler cavity |

| Net CO₂ / sheet | 0.8–1.4 lb | Drives sheet count |

| Flex temp | Pliable to –60 °C | No cracking in pack‑out |

Sheet Count FormulaSheets = (Product lb × 0.45 × Days) ÷ Sheet lb

15 lb ice‑cream, 2 days, 1 lb sheets → 14 sheets.

Hybrid Hack: Side‑wall sheets + one top block extends runtime 12 % with no extra weight.

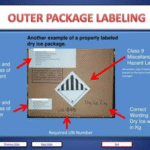

6. Safety & 2025 Label Updates

| Rule / Agency | 2025 Change | Your Action |

|---|---|---|

| DOT § 173 | Fine ↑ to USD 17 062 per mis‑label | Use QR‑coded UN 1845 labels |

| FDA Food Code 2022 | Meal kits need “Releases CO₂” sticker | Add 3 ¢ label |

| FedEx / UPS | Dry‑ice fee ⇒ USD 8 | Bake into freight quotes |

OSHA warns frostbite occurs in < 30 s at –78 °C—cryogloves & ANSI Z87.1 goggles are non‑negotiable.

7. Cost‑Saving & Sustainability Hacks

-

Mid‑week buying: Tuesday dry‑ice spot rates are ~10 % lower than Friday.

-

VIP liners: R‑25 panels cut ice weight 40 %, paying back after 3 shipments.

-

Carbon‑capture CO₂ contracts: Trim Scope 3 footprint 50 % & lock price for 3 yrs.

-

AI load planning: Digital twins reduce unused ice 11 %.

Case study: Meal‑kit brand using sheets + VIP cut cold‑chain spend 29 % and hit 99.4 % frozen‑on‑arrival.

8. 2025‑2030 Market & Tech Outlook

| Trend | What’s Coming | Benefit |

|---|---|---|

| Mini sheet‑presses | 50 lb h‑¹ onsite production | Zero freight costs |

| Return‑loop VIP | 90 % panel reuse | –55 % Scope 3 CO₂ |

| Smart CO₂ vents | Bluetooth sensors confirm airflow | Faster TSA clearance |

| AI route twins | Predict sublimation ±4 % | Cuts over‑packing |

Dry‑ice demand to grow 7.8 % CAGR through 2030, with sheets as the fastest‑rising format.

9. FAQ

How long will sheets keep food frozen? 24–48 h at 25 °C; +5 lb adds ~6 h.

Are sheets TSA‑approved? Yes, but they count toward the 5.5 lb dry‑ice limit.

Do sheets cost more than blocks? ≈ 15 % lb‑for‑lb, but save 20–40 % on freight weight.

Can I reuse sheets? Envelope yes; CO₂ sublimates—some vendors offer refill kiosks.

What’s the biggest compliance mistake? Sealing vents—can build 50 psi in hours and trigger DOT fines.

10. Summary & Action Plan

-

Run the Sizing Formula (package or sheet) before every lane.

-

Vent, label, declare—dot‑fine proof your shipments.

-

Upgrade to VIP + Sheets to slash ice 40 %.

-

Lock mid‑week CO₂ contracts for cost & ESG wins.

-

Monitor with smart loggers and iterate quarterly.

Ready to ship colder, cheaper, greener? [Book a 15‑min consult with Tempk] and transform your 2025 cold‑chain today.