In the world of cold chain logistics, transporting temperature-sensitive goods like pharmaceuticals, biological samples, and perishable foods requires precision and care. Dry ice packs with 96 cells have become an essential tool in ensuring these goods stay at their required temperatures during transit. This guide will walk you through the use, benefits, and best practices for shipping with dry ice packs 96 cells in 2025, including how to stay compliant with current regulations and leverage the latest innovations.

-

Understanding Dry Ice Packs: Learn what 96-cell dry ice packs are and how they help maintain consistent temperatures for sensitive goods.

-

Shipping Compliance: Know the labeling, packaging, and documentation requirements to stay compliant with 2025 regulations.

-

Best Practices: Discover practical packing and shipping tips to ensure your goods arrive safely and on time.

-

2025 Trends: Stay updated on the latest developments in dry ice shipping, including sustainability and technology advancements.

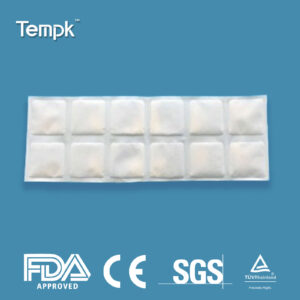

What Are Dry Ice Packs 96 Cells and How Do They Work?

Dry ice packs 96 cells are designed for the transportation of temperature-sensitive goods. These packs are composed of 96 small chambers filled with dry ice, which provides a consistent and controlled cooling environment for perishable items. The 96-cell configuration allows for gradual sublimation of the dry ice, ensuring that the temperature of the goods remains stable and safe for extended periods.

Why does this matter to you? When shipping pharmaceuticals, biological samples, or perishable foods, maintaining a specific temperature range (e.g., 2-8°C for many drugs) is critical. Traditional gel packs may not offer long enough cooling duration, which is where 96-cell dry ice packs shine. They are ideal for long-distance shipments, especially when traveling through hot climates or over multiple days.

Advantages of Dry Ice Packs 96 Cells

| Feature | Description | Benefits |

|---|---|---|

| Cooling Duration | Typically lasts up to 72 hours | Ensures reliable cooling for long-duration shipments |

| Cell Structure | 96 small chambers for uniform cooling | Prevents temperature fluctuations, ensuring even cooling |

| Material Compatibility | Suitable for pharmaceuticals, food, and biological samples | Maintains product integrity during transport |

How to Effectively Use Dry Ice Packs 96 Cells for Shipping

To maximize the effectiveness of dry ice packs 96 cells, follow these steps for proper packing, compliance, and shipping:

Step 1: Pre-Shipment Preparation

Before packing, ensure that your shipment and packaging are ready:

-

Pre-chill both your product and shipping container to avoid thermal shock, which could damage sensitive materials.

-

Calculate the right quantity of dry ice: A general guideline is 5-10 lbs of dry ice per 24 hours of transit, depending on insulation and ambient temperature conditions.

-

Avoid overpacking: Ensure that the number of dry ice packs is sufficient for the expected journey but not excessive, which can lead to dangerous CO₂ buildup.

Step 2: Proper Packing Techniques

-

Layer the dry ice packs on the bottom or sides of the container, ensuring there is a buffer between the dry ice and the goods to prevent freezing.

-

Vent the container: Always use a container that allows CO₂ gas to escape during sublimation. This is crucial to avoid pressure buildup, which could damage the package.

-

Seal properly: If using Styrofoam, ensure it is not sealed completely. Vent holes or plugs are necessary for safe shipping.

Step 3: Shipping and Monitoring

-

Monitor the temperature during transit using data loggers to ensure that your dry ice packs are performing as expected.

-

Communicate with the carrier to inform them of the dry ice contents and ensure they follow proper handling procedures.

When to Choose Dry Ice Packs 96 Cells Over Other Cold Chain Solutions

Dry ice packs 96 cells are ideal in situations where precise temperature control and extended cooling are necessary. Consider using them over traditional gel packs or phase change materials (PCMs) in these scenarios:

-

Long-Duration Shipments: For shipments exceeding 24 hours, dry ice packs 96 cells provide more consistent cooling.

-

Hot Climates: When shipping in high temperatures, dry ice provides more reliable cooling than other alternatives.

-

Critical Shipments: For high-value items like pharmaceuticals, vaccines, and biological samples, these packs offer superior protection and reliability.

Key Scenarios for Dry Ice Packs 96 Cells

| Scenario | Cooling Requirement | Why It Works |

|---|---|---|

| International Shipping | Long duration (3+ days) | Provides consistent cooling over multiple days, ensuring product safety |

| Tropical Regions | High ambient temperatures | Prevents temperature fluctuations that could damage sensitive goods |

| Biological Shipments | Precise 2-8°C control | Gradual sublimation prevents temperature spikes and ensures steady cooling |

Regulatory Compliance in 2025: How to Stay Safe

Shipping dry ice is regulated by various agencies, including the International Air Transport Association (IATA), the U.S. Department of Transportation (DOT), and the International Maritime Organization (IMO). To stay compliant:

-

Labeling: Clearly mark packages with “Dry Ice” or “Carbon Dioxide, Solid,” the UN1845 code, and the Class 9 hazard label.

-

Documentation: For air shipments, ensure that a Shipper’s Declaration for Dangerous Goods is included.

-

Weight Limits: Comply with IATA’s limit of 200 kg per package for air cargo, and check other carrier-specific rules.

Compliance Checklist

| Element | Required Action | Benefit |

|---|---|---|

| UN1845 Label | Ensure the UN1845 number is visible | Ensures global recognition and avoids shipment delays |

| Class 9 Label | Apply the Class 9 hazard label | Speeds up acceptance and reduces confusion |

| Shipper Declaration | Include if shipping via air and carrying >2.5 kg dry ice | Ensures compliance with hazardous material regulations |

| Weight Documentation | Accurately declare the weight of dry ice | Avoids fines and shipment rejections |

2025 Trends in Dry Ice Shipping: What’s New?

The cold chain logistics industry is continuously evolving. In 2025, key trends include:

-

Smart Packaging: IoT-enabled packaging provides real-time monitoring of dry ice conditions during transit.

-

Sustainability: More companies are turning to CO₂ recovery pelletizers and recyclable packaging materials to reduce their environmental impact.

-

Advanced Insulation: New insulation materials enhance dry ice efficiency by reducing sublimation rates and extending cooling durations.

Frequently Asked Questions

How long do dry ice packs 96 cells last during transit?

Dry ice packs 96 cells typically last between 48 to 72 hours, depending on the quantity used, insulation, and ambient temperature during transit.

Can dry ice packs 96 cells be used for food shipments?

Yes, these packs are ideal for shipping perishable foods like seafood, meats, and dairy, ensuring that they stay frozen during transit.

Are there weight limits for dry ice shipments?

Yes, air cargo shipments are limited to 200 kg of dry ice per package, while ground shipments generally have no weight restrictions but must follow other packaging and labeling guidelines.

Conclusion

Dry ice packs 96 cells are an essential tool for transporting temperature-sensitive goods. By adhering to the latest shipping regulations and implementing best practices, you can ensure that your shipments arrive safely and on time, while staying compliant with 2025 cold chain logistics standards.

Next Steps

-

Assess your shipping needs: Determine the required cooling duration and select the appropriate dry ice pack size.

-

Ensure compliance: Review your packaging, labeling, and documentation practices to align with 2025 regulations.

-

Contact Tempk: If you need assistance with packing or cold chain logistics, consult a Tempk expert to optimize your shipping process.

About Tempk

Tempk provides advanced cold chain solutions, including high-quality dry ice packs 96 cells. We specialize in ensuring the safe and efficient transport of temperature-sensitive goods across industries like pharmaceuticals, food, and biotechnology. Our products meet all regulatory requirements, ensuring smooth and compliant shipping.

Contact Tempk today for expert advice on your cold chain logistics needs.