Introduction

In cold chain logistics, dry ice pellets and dry ice packs have become essential cooling tools for maintaining product integrity from warehouse to destination. Whether you’re shipping vaccines, seafood, or laboratory samples, choosing the right dry ice form determines not just temperature stability—but your operational efficiency and cost control.

In this 2025 guide, you’ll learn how to select and apply dry ice solutions that match your logistics goals, regulatory requirements, and sustainability standards.

-

The key differences between dry ice pellets and dry ice packs

-

Best-use cases across pharmaceutical, food, and logistics sectors

-

Storage and safety practices for dry ice handling

-

2025 innovations improving cold chain sustainability

-

How to maximize cooling performance while reducing waste

What Are Dry Ice Pellets and How Are They Used in Cold Chain Logistics?

Dry ice pellets are small, cylindrical pieces of solid carbon dioxide (CO₂) designed for fast, direct cooling. Because they sublimate—turning directly from solid to gas—they leave no liquid residue, making them ideal for temperature-sensitive goods.

They are widely used in industries where maintaining ultra-low temperatures is critical, including pharmaceutical shipping, biotech samples, and frozen food transport.

How Do Dry Ice Pellets Work in Practice?

Dry ice pellets rapidly absorb heat energy, producing intense cooling at -78.5°C (-109°F). This quick temperature drop ensures products remain frozen during long-distance transport. The pellets’ small surface area allows even distribution inside insulated boxes or shipping containers, offering consistent thermal coverage.

Comparative Overview: Dry Ice Pellets vs. Other Cooling Options

| Cooling Method | Temperature Range | Duration | Ideal Application | Real-World Benefit |

|---|---|---|---|---|

| Dry Ice Pellets | -78.5°C | 24–48 hours | Ultra-cold shipping | No liquid residue, precise temperature control |

| Dry Ice Packs | -40°C to -60°C | 36–72 hours | Medium-term cooling | Slower sublimation, reusable, flexible placement |

| Gel Packs | 0°C to -20°C | 12–24 hours | Perishable food transport | Budget-friendly, reusable |

| Phase Change Materials (PCM) | Customizable | 24–96 hours | Biopharma or diagnostic kits | Stable temperature bands |

Practical Tips for Using Dry Ice Pellets

-

For pharma: Use high-density pellets in vacuum-insulated shippers for maximum efficiency.

-

For food: Line pellets evenly under and around products to avoid partial thawing.

-

For logistics: Combine pellets with phase change materials for extended multi-zone shipping.

Example: A vaccine shipment requiring -70°C stability for 48 hours achieved optimal results using 5kg of 3mm dry ice pellets in a high-performance EPS container, reducing spoilage risk by 40%.

When Should You Use Dry Ice Packs Instead of Pellets?

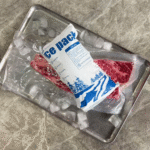

Dry ice packs are sealed containers filled with compressed CO₂ snow or frozen CO₂ slurry. They are engineered to provide longer cooling duration with less vapor release, making them ideal for mid-temperature shipments or reusable logistics systems.

Advantages of Dry Ice Packs in 2025 Cold Chain Operations

-

Extended Cooling Duration – Up to 72 hours of stable temperature.

-

No Direct Contact Risk – Safer for workers handling large shipments.

-

Reusable Design – Reduces packaging waste and operational costs.

-

Customizable Sizes – Fit insulated boxes, crates, and pallets easily.

Key Differences Between Dry Ice Pellets and Packs

| Feature | Dry Ice Pellets | Dry Ice Packs | What It Means for You |

|---|---|---|---|

| Cooling Speed | Very fast | Gradual | Choose pellets for quick freeze; packs for controlled cooling |

| Reusability | Single-use | Multi-use | Packs are better for recurring shipments |

| Handling | Requires PPE | Safer to handle | Packs reduce CO₂ exposure |

| Cost | Lower per kg | Higher per unit | Depends on shipment frequency |

Case Insight: A seafood exporter replaced pellet-based shipping with reusable dry ice packs, cutting packaging waste by 60% while maintaining -40°C consistency for 72 hours.

How to Handle and Store Dry Ice Safely in Your Cold Chain Operations

Dry ice offers significant thermal benefits—but it demands proper handling. Unsafe storage or ventilation can cause pressure buildup or CO₂ exposure hazards.

Storage Guidelines

-

Store dry ice in ventilated areas, never in airtight containers.

-

Keep storage rooms between -80°C and -20°C for optimal retention.

-

Avoid direct skin contact; always use insulated gloves.

-

Rotate inventory using the first in, first out (FIFO) system.

Transportation Tips

-

Use insulated containers with venting holes to prevent CO₂ accumulation.

-

Track internal temperatures using digital data loggers or IoT sensors.

-

Train staff in emergency procedures for CO₂ leaks or frostbite cases.

| Risk Type | Cause | Prevention | Impact on You |

|---|---|---|---|

| CO₂ buildup | Poor ventilation | Install exhaust fans | Prevents worker hazards |

| Product thawing | Improper insulation | Use EPS or vacuum panels | Reduces product loss |

| Frostbite | Direct contact | Use insulated gloves | Ensures worker safety |

Safety Note: In 2025, most logistics facilities are adopting smart CO₂ sensors integrated with AI ventilation control to maintain compliance with ISO 23412 cold chain safety standards.

How to Maximize Cooling Efficiency and Reduce Costs in 2025

Dry ice remains a cost-effective and sustainable solution when applied strategically. To reduce both energy waste and material cost, companies are integrating smart temperature monitoring and hybrid cooling systems.

Optimization Strategies

-

Use the Right Format: Pellets for flash freezing; packs for steady cooling.

-

Pre-Chill Packaging: Reduces the sublimation rate by up to 15%.

-

Combine with Insulated Liners: Extends cooling duration by 20–30%.

-

Monitor Sublimation Loss: Use smart tracking devices to optimize replenishment cycles.

Industry Data (2025): Companies implementing hybrid dry ice-pack systems reported a 25% improvement in temperature consistency and 18% reduction in cooling material costs.

Sustainability Angle

Modern cold chain players are embracing CO₂ recovery systems, allowing dry ice to be produced from captured emissions—supporting circular economy goals and carbon neutrality.

2025 Trends in Dry Ice Cooling Technology

The cold chain sector is rapidly evolving, with dry ice technology at the forefront of sustainable logistics innovation.

Key Advancements

-

Automated Pelletizers: Produce consistent pellet size, reducing waste.

-

Reusable Dry Ice Sheets: Combine flexibility of packs with pellet cooling power.

-

Smart Monitoring Sensors: Track real-time CO₂ levels and sublimation rates.

-

Bio-based Packaging Integration: Reduce single-use plastics in thermal boxes.

Emerging Market Insights

-

Pharma Cold Chain: Growing at 7.3% CAGR, driven by biologic drug shipments.

-

E-commerce Food Delivery: Increased 35% in 2025, requiring mid-range cooling solutions.

-

Sustainable Logistics: Over 60% of providers now adopt reusable pack systems.

Frequently Asked Questions

Q1: How long do dry ice pellets last in transit?

Typically, 24–48 hours, depending on insulation quality and external temperature.

Q2: Can dry ice packs replace regular ice packs?

Yes, especially for shipments requiring temperatures below -40°C. They offer longer performance and no water residue.

Q3: Is dry ice safe for air transport?

Yes, but must comply with IATA Dangerous Goods Regulations (Section 5.5.3), requiring labeling and vented containers.

Q4: How do I know how much dry ice to use?

As a rule, allocate 5–10 kg of dry ice per 24-hour shipment per 100 liters of insulated volume.

Q5: What are the best eco-friendly alternatives to traditional dry ice?

Bio-CO₂ pellets and reusable phase-change packs with recyclable outer shells.

Summary and Recommendations

Dry ice pellets and dry ice packs each serve distinct roles in cold chain logistics.

Pellets excel in rapid, ultra-cold applications, while packs deliver steady, reusable cooling for extended durations. The optimal choice depends on your product sensitivity, transport duration, and sustainability goals.

Key Takeaways

-

Use dry ice pellets for pharmaceutical or flash-freeze operations.

-

Choose dry ice packs for reusable, mid-temperature deliveries.

-

Prioritize smart tracking and hybrid cooling for cost efficiency.

-

Integrate CO₂ recovery systems for greener operations.

Next Steps

-

Audit your cold chain setup – Identify temperature-critical stages.

-

Select the right ice format based on duration and sensitivity.

-

Upgrade to smart containers with digital thermal monitoring.

-

Partner with certified suppliers for consistent dry ice quality.

Action Tip: For complex shipping needs, test both dry ice pellets and packs under controlled conditions to determine which offers the best cost-temperature ratio for your operation.

About Tempk

At Tempk, we specialize in advanced cold chain packaging and temperature-control solutions that keep your products safe from origin to destination.

Our expertise covers dry ice technology, insulated shippers, and IoT-based temperature monitoring—trusted by pharmaceutical, food, and logistics leaders worldwide.

We continuously innovate with eco-friendly materials and CO₂-efficient production methods to help your business meet performance and sustainability goals.

Call to Action:

Want to optimize your cooling systems for 2025? Contact our experts for tailored advice and free cold chain performance analysis.