Dry Ice Supplier Dry Ice Pack: How to Choose in 2025

If you want fewer excursions and lower cost per delivery, standardize on the right dry ice supplier dry ice pack and a simple sizing SOP. It runs at −78.5 °C, vents ~541 L of CO₂ per kg, and—when paired with better insulation—can cut dry‑ice mass by 20–40%. This guide merges three 2025 playbooks into one practical blueprint you can ship tomorrow.

-

How to size a dry ice supplier dry ice pack for 24–120 hours with a lane‑ready formula and buffers.

f303e865-8a95-4796-8120-1216e61…

-

Which film thickness and venting prevent bursts at −78.5 °C, and why.

f303e865-8a95-4796-8120-1216e61…

-

How to qualify a dry ice supplier dry ice pack partner in 2025 (docs, service, compliance).

dry-ice-supplier-dry-ice-pack-2…

-

Pack‑out layouts that keep payloads frozen while avoiding freeze‑burn and pressure spikes.

f303e865-8a95-4796-8120-1216e61…

-

What to label and log to pass acceptance checks and avoid fines or delays.

dry-ice-supplier-dry-ice-pack-2…

How do you size a dry ice supplier dry ice pack for 24–120 hours?

Short answer: Use a simple heat‑load proxy, then add climate buffer and split mass Bottom 50% / Sides 35% / Top 15%. Start with:Dry Ice (kg) ≈ 0.10 × Box Volume (L) × Transit Days × Insulation Factor (IF)

IF: VIP 0.7, PUR 0.8, EPS 1.0, Corrugated 1.5. Add +10% buffer for warm routes, +20% for hot.

f303e865-8a95-4796-8120-1216e61…

More context: You don’t need a PhD or CFD model to hit target holds. This lane‑tested rule gets you close, fast. For a 20 L EPS shipper over 72 h: 0.10×20×3×1.0 = 6.0 kg. Convert mass to your pack menu (e.g., bricks for base load, sheets to wrap sides, top‑offs for variability). Better insulation (EPS→PUR or VIP) reduces dry‑ice mass and stabilizes gradients, which lowers claims and freight.

f303e865-8a95-4796-8120-1216e61…

What film thickness and venting stop bursts at −78.5 °C?

Detail: Pick HDPE 110–120 μm for standard lanes or PET/PE 130–150 μm for rough, long routes; then add micro‑venting. Target 0.5–1.5 mm² total vent area per 5 kg split across two spots. This prevents dangerous bulge without meaningfully shortening hold time.

f303e865-8a95-4796-8120-1216e61…

| Film & Vent Choice (2025) | Typical Gauge | Crack Risk | What it means for you |

|---|---|---|---|

| LDPE | 70–90 μm | Medium–High | Use only for short, gentle lanes |

| HDPE | 110–120 μm | Low–Medium | E‑commerce frozen standard |

| PET/PE laminate | 130–150 μm | Low | Pharma/export lanes; tougher seams |

| Venting (total area) | 0.5–1.5 mm² / 5 kg | — | Two vents: top seam + side panel |

Practical tips

-

Pre‑condition packs and product; avoid warm packouts that waste mass.

f303e865-8a95-4796-8120-1216e61…

-

Keep a gas path open; never tape lids airtight. CO₂ is heavier than air.

f303e865-8a95-4796-8120-1216e61…

-

Use separators to prevent freeze‑burn on cartons and pouches.

f303e865-8a95-4796-8120-1216e61…

Real‑world case: A national frozen‑meal brand standardized PET/PE 135 μm with dual micro‑vents and switched EPS→PUR. Failures fell 68%, dry‑ice use dropped 19%, and on‑time safe‑temp delivery improved 3.4% across 72‑h lanes.

f303e865-8a95-4796-8120-1216e61…

How do you qualify a dry ice supplier dry ice pack partner in 2025?

Short answer: Treat the pack as a critical component. Demand food‑grade CO₂ docs, multiple formats in stock, vented packaging, fast cut‑offs, and acceptance‑check support (UN 1845, PI 954). Use RFP guardrails so quality survives peak season.

dry-ice-supplier-dry-ice-pack-2…

More context: The best partners provide letters of guaranty, film/seam specs, and training. They stock pellets, nuggets, and blocks; print labels; and coach teams through air and ground checklists. Favor local production to reduce sublimation loss and improve freshness; distance kills performance before packout. Ask about just‑in‑time runs and weekend delivery to avoid stale ice.

report4

What compliance boxes must you tick in 2025?

Detail: Mark UN 1845 (Dry ice/Carbon dioxide, solid) with net dry‑ice mass. Packaging must vent. FAA passenger packages cap at 2.5 kg. USPS mailpieces cap at 5 lb. Stage and vehicles must be ventilated; OSHA’s 8‑hr CO₂ limit is 5,000 ppm—install monitors.

dry-ice-supplier-dry-ice-pack-2…

| Rule/Checklist | Core Requirement | What it means for you |

|---|---|---|

| IATA PI 954 (air cargo) | Vented pack, UN 1845, net mass on waybill | Build & label for fast acceptance |

| FAA passenger baggage | ≤ 2.5 kg, not airtight | Protect travelers, avoid fines |

| USPS limits | ≤ 5 lb per mailpiece | Mind carrier caps |

| OSHA CO₂ | 5,000 ppm TWA | Vent docks; add CO₂ monitors |

Copy‑ready RFP guardrails (paste into your PO)

-

Food‑grade CO₂ per FDA 21 CFR 184.1240; current letter of guaranty.

-

Vented PE/EVA 3–4 mil or PET/PE laminate; welds ≥ 6 mm; rounded seam ends.

-

Formats on hand: pellets (3 mm, 16 mm), nuggets (¼–¾″), 10/25/50 lb blocks.

-

Labels and job aids for UN 1845, PI 954; weekend delivery and surge capacity.

dry-ice-supplier-dry-ice-pack-2…

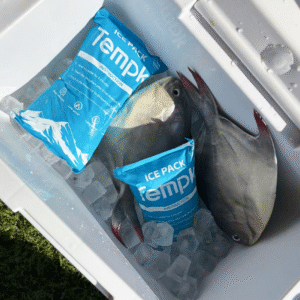

What layout keeps payloads frozen longer with a dry ice supplier dry ice pack?

Short answer: Layer cold from below and around the sides, keep headspace clear, and log one box per batch. Use bricks for base load, sheets on the sides, and a small top‑off.

f303e865-8a95-4796-8120-1216e61…

More context: For 24–48 h parcel lanes (EPS 10–20 L), place 2–3 sheets under product, 2 on sides, 1 on top; add thin corrugated to avoid freeze‑burn. For 48–72 h EPS 20–40 L, bricks bottom (40–60%), sheets sides (30–40%), small top‑off (10–20%). VIP/PUR lanes benefit from sleeves and corner pads. Always allow a vent path; never compress lid seals airtight.

f303e865-8a95-4796-8120-1216e61…

When should you pick gel packs or PCMs instead of a dry ice supplier dry ice pack?

Detail: If product may not freeze, use gel (≈0 °C) or PCMs (−20/−10/+2–8 °C) alone, or run a hybrid—dry ice beneath, PCM above—to smooth gradients. For must‑stay‑frozen payloads, the dry ice supplier dry ice pack wins on dryness and range.

f303e865-8a95-4796-8120-1216e61…

| Coolant | Temperature Band | Typical Duration | What it means for you |

|---|---|---|---|

| Dry ice supplier dry ice pack | −78.5 °C effective | 24–120 h | Frozen food, biologics, lab |

| Gel packs | 0 to −2 °C | 6–36 h | Fresh, not frozen |

| PCM bricks | −20/−10/+2–8 °C | 24–96 h | Pharma ranges; hybrid builds |

Practical on‑floor tips

-

Separate product from dry ice with cardboard or pads to prevent surface damage.

report4

-

Vent insulated lids; never hermetically seal—pressure rupture risk.

report4

-

Label UN 1845 + net mass; avoid old hazard labels on reused cartons.

report4

Hands‑on SOP snippet: “Logger one carton per batch for 24–48 h; bulge < 25 mm after 10–20 min; if higher, increase vents.”

f303e865-8a95-4796-8120-1216e61…

2025 Dry Ice Supplier Dry Ice Pack developments and trends

Trend overview: Expect bio‑laminated PET/PE, nano‑barrier coatings that slow pressure growth, smart indicators, and automated dispensers for exact pack counts. Combined with insulation upgrades, teams report 10–25% less dry ice with better arrivals. Local production hubs continue to expand, improving freshness and resilience.

f303e865-8a95-4796-8120-1216e61…

report4

Latest at a glance

-

Bio‑laminated films: Lower footprint, same toughness.

f303e865-8a95-4796-8120-1216e61…

-

Nano‑barrier coatings: Flatter early‑stage bulge, safer handling.

f303e865-8a95-4796-8120-1216e61…

-

IoT loggers as standard: Faster interventions on lanes.

report4

Market insight: Full‑service suppliers now bundle insulated boxes, calculators, regulatory aids, and data logging. Expect integrated ordering plus next‑day replenishment from regional plants for demand spikes.

report4

Frequently Asked Questions

How many packs for a 20 L box over 48 h?

Plan ~4–5 kg total—e.g., 3×1 kg bricks + 2×0.5 kg sheets for EPS. Validate with a logger in your lane.

f303e865-8a95-4796-8120-1216e61…

Will venting waste cold?

Proper micro‑vents prevent dangerous pressure spikes with minimal impact on duration. Oversized vents do waste refrigerant—pilot first.

f303e865-8a95-4796-8120-1216e61…

What’s the practical temperature range inside the shipper?

At the pack, −78.5 °C; near the payload, typically −78.5 to ~−60 °C depending on insulation and layout.

f303e865-8a95-4796-8120-1216e61…

What labels do I need for air shipments?

UN 1845 name and net dry‑ice mass; packaging must vent; follow IATA PI 954 acceptance checks.

dry-ice-supplier-dry-ice-pack-2…

Is mixing gel or PCMs with dry ice okay?

Yes—run dry ice beneath and PCMs above to smooth gradients; keep gels off the product to avoid freeze‑burn.

f303e865-8a95-4796-8120-1216e61…

Summary & recommendations

Recap: Standardize on a dry ice supplier dry ice pack spec (HDPE 110–120 μm or PET/PE 130–150 μm with micro‑vents), size with the 0.10×Volume×Days×IF rule plus climate buffer, and split mass Bottom/Sides/Top. Upgrade insulation before adding mass, then train teams on venting and labeling.

f303e865-8a95-4796-8120-1216e61…

Next steps (CTA):

-

Pilot two builds on your longest lane for 72–96 h.

-

Lock a single supplier spec and publish a one‑page SOP.

-

Train & audit weekly (seams, bulge, logger trace). Talk to Tempk for a vendor shortlist and a copy‑ready SOP packout template.