Dry Ice to Keep Food Cold: 2025 How‑To & Calculator

Updated: August 19, 2025. If you need dry ice to keep food cold, plan 5–10 lb per 24 h in a well‑insulated shipper, keep the package vented, and follow UN1845 labeling. For air travel, the common passenger limit is 2.5 kg (5.5 lb) per person; for USPS air, ≤5 lb per mailpiece domestically. This consolidated guide merges and upgrades your three drafts for 2025 SEO and compliance.

-

How does dry ice to keep food cold work? (frozen vs. refrigerated, plain‑English)

-

How much dry ice for 24–72 hours? (quick estimator and packout)

-

How to pack dry ice to keep food cold safely? (layering, venting, labeling)

-

What are the 2025 rules and limits? (FAA, IATA, USPS, carrier job aids)

-

When to choose gel or PCM instead of dry ice? (use cases and cost control)

What does “dry ice to keep food cold” really mean—and when should you use it?

Short answer: Use dry ice to keep food cold when you need a frozen result; use gel or PCM when you need ≤40°F refrigeration. Dry ice is solid CO₂ at about −109.3°F (−78.5°C). It sublimates (turns to gas), so packages must vent for safety. Frozen targets track to 0°F; refrigerated targets to ≤40°F.

Why it matters to you: Start with your temperature goal. If “arrives rock‑solid” is the KPI, choose dry ice. If “arrives chilled” is enough, gel or −20°C PCM bricks are simpler, avoid hazmat paperwork, and often lower total cost. In real shipments, insulation quality, void space, and how often you open the box drive results—so right‑size coolant and pack tight.

Dry ice vs. gel packs vs. PCM for shipping food

Pick the refrigerant that matches the job. Dry ice to keep food cold excels at deep‑freeze stability for 24–72 h. Gel packs hold near 32°F for chilled lanes. PCM bricks (e.g., −20°C or +5°F) deliver a stable setpoint and can reduce dry‑ice mass by smoothing spikes. Run a one‑box pilot on your hottest lane before scaling.

| Refrigerant (Use Case) | Typical Temp | Baseline Amount | What it means for you |

|---|---|---|---|

| Dry ice (UN1845) – frozen foods 24–72 h | ~−109.3°F | 5–10 lb per 24 h per box | Arrives frozen; requires venting + UN1845 label. |

| PCM bricks (−20°C / +5°F) – stable frozen/chilled | Setpoint‑specific | Match to qualified duration | Extends runtime; reduces dry‑ice burn/cold shock. |

| Gel packs – ≤40°F refrigeration | ~20–32°F | Full coverage around payload | Simple, reusable, no hazmat labels. |

Practical tips you can apply today

-

Separate goals: Frozen meats/ice cream in a dry‑ice box; drinks or produce in a gel‑pack box to avoid frequent openings.

-

Place dry ice on top: Cold sinks. Use a spacer (cardboard/rack) to protect packaging and improve vapor flow.

-

Fill voids tightly: Paper/foam dunnage cuts convection and extends hold time.

Real case: A bakery moved from a single bottom charge to a top + bottom dry‑ice layout with corrugated spacers. The switch held center temps below −10°C for a 2‑day summer lane while reducing dry‑ice use ~12%.

How much dry ice to keep food cold for 24–72 hours?

Rule of thumb: 5–10 lb per 24 h in a quality, well‑packed cooler or shipper. Start mid‑range, then adjust after a one‑box test. Hot routes, sun exposure, and extra headspace push you toward the upper end. For long weekends or high risk of delay, add a buffer day.

What changes the number? Insulation thickness, product pre‑chill, the ratio of ice blocks vs. pellets (blocks sublimate slower), and how often the box is opened. High‑R liners (VIP/EPS/EPP) and snug void‑fill can cut coolant mass markedly.

Dry ice to keep food cold—quick estimator (copy/paste)

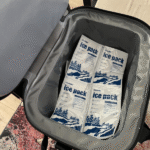

How to pack dry ice to keep food cold (step‑by‑step)

For a frozen outcome:

-

Pre‑freeze contents; pre‑chill the shipper.

-

Bottom layer: spacer + a dry‑ice block.

-

Middle: payload centered, tight, level.

-

Top layer: the majority of dry ice to keep food cold goes on top.

-

Fill voids fully.

-

VENT (never airtight).

-

Mark & label: “Dry Ice/Carbon Dioxide, solid”, UN1845, net weight (kg), Class 9 diamond.

| Add‑On | Why it helps | What to look for | Your payoff |

|---|---|---|---|

| VIP liner / 2″ EPS | Lowers heat gain | Verified R‑value, tight seams | Fewer pounds, more hours |

| Thin PCM “shield” | Buffers cold shock | Correct melt point (e.g., +5°F) | Protects delicate packaging |

| Hydrated ice sheets | Fill voids & cushion | Food‑contact statement | More uniform temps |

2025 rules for dry ice to keep food cold (flying & shipping)

Passengers (you on a plane): Up to 2.5 kg (5.5 lb) per person per package with airline approval. Package must vent and be marked (“Dry Ice/Carbon Dioxide, solid” + net wt). Frozen gel packs are OK when frozen solid at screening.

USPS (domestic air): Dry ice allowed ≤5 lb per mailpiece, vented packaging, correct markings; international mail prohibited.

Air cargo (FedEx/UPS): When used only as a refrigerant for non‑DG contents, many lanes use the IATA acceptance checklist instead of a full DG declaration—but you still need UN1845, net kg, and the Class 9 label on the same panel when space allows.

Sample outer‑box marking you can copy

Can you fly with dry ice to keep food cold?

Yes—within the 2.5 kg limit and airline approval. Keep the package vented; never ride with large amounts in a sealed passenger space. For vehicles and staging rooms, remember common exposure thresholds cited by regulators: TWA 5,000 ppm and STEL 30,000 ppm for CO₂; use gloves to prevent frostbite.

When not to use dry ice to keep food cold (and what to use instead)

If your spec is ≤40°F refrigeration, skip dry ice and go gel/PCM‑only. Benefits: no venting, no UN labels, easier hand‑offs for 3PLs, and fewer acceptance delays. For hot last‑mile windows, add a +5°F PCM near the product to flatten spikes.

Quick scenarios and exact actions

-

Warm‑route pastries (48 h): Use hydrated sheets top & bottom + two +5°F PCM bricks on the long sides; VIP liner; no DG labels.

-

Mixed cargo road trip (24–36 h): 15–20 lb dry ice in a 45‑qt cooler for frozen meats; a separate gel‑pack cooler for drinks to avoid frequent openings.

-

Power outage at home: Keep doors closed; if extended, move perishables into a gel‑pack cooler or add dry ice to the freezer.

Actual outcome: A D2C bakery kept cakes at 34–38°F across a 2‑day warm lane using sheets + +5°F PCM and no dry ice, cutting fees and avoiding DG acceptance rejections.

2025 trends in using dry ice to keep food cold

What’s new this year: Carriers and IATA sharpened acceptance checklists and label placement guidance; networks continue to endorse the 5–10 lb/day baseline for planning. More shippers are hybridizing (PCM near product + a smaller top dry‑ice layer) to reduce coolant mass while holding setpoints. Sustainability efforts include captured‑CO₂ dry ice and reusable coolers, and IoT tags are common for lane validation.

Latest progress at a glance

-

Clearer acceptance forms: Faster audits and fewer rejections when UN1845/net‑kg are on the same panel.

-

Hybrid packouts rise: PCM shields cut cold shock and dry‑ice pounds.

-

Home resilience: ~50 lb of dry ice can hold a typical freezer about two days with doors closed—useful during outages.

Market insight: Frozen e‑commerce continues to expand at double‑digit rates in several regions, pushing demand for validated, lower‑waste packouts and better insulation.

FAQ

How much dry ice to keep food cold for 48 hours?

Start at 10–20 lb total (5–10 lb per 24 h) per insulated box; add a buffer day in summer and verify with a data logger.

Can dry ice touch food directly?

Avoid direct contact to prevent cold burn. Use a liner or cardboard spacer between CO₂ blocks and product.

Is dry ice safe in a car or small room?

Only with good ventilation. CO₂ can displace oxygen; crack windows and avoid confined spaces when staging many boxes.

Do gel or PCM packs require hazmat labels?

No. They don’t release gas. Use them when refrigerated ranges are acceptable.

Can I mail dry ice domestically?

Yes, with vented packaging and proper UN1845 markings. For air, many postal networks cap at ≤5 lb per piece; international is typically not allowed.

Summary & recommendations

Choose by temperature: For frozen, use dry ice to keep food cold; for ≤40°F, pick gel/PCM. Size correctly: Plan 5–10 lb per 24 h, place most on top, fill voids, and add a buffer for hot lanes. Comply in 2025: UN1845, net kg, Class 9 label, and venting; passengers ≤2.5 kg. Validate once, then standardize the SOP with photos and a check‑list.

Next steps (quick plan):

-

Define frozen vs. chilled.

-

Use the estimator above to size coolant.

-

Run one pilot with a logger; tweak pounds or insulation.

-

Print UN1845 labels and a pre‑tender checklist; train your team.

-

Roll out the standard packout across lanes.

About Tempk

We engineer cold‑chain kits that hit your temperature‑time targets at the lowest landed cost. Our team validates dry ice to keep food cold against gel and PCM in bench tests and live pilots, then delivers SOPs, label templates, and safety cards so your team ships confidently year‑round.

CTA: Want a lane‑specific spec for your SKUs? Talk to a Tempk specialist—we’ll size coolant and insulation for your actual routes.