Effective Use of Dry Ice Pack Coolers for Cold Chain Logistics in 2025

Shipping temperature-sensitive goods is a delicate process that requires precision. Dry ice pack coolers are a vital solution for ensuring optimal conditions during transit, especially in 2025, as they offer significant advantages over traditional methods. This article explores how dry ice coolers work, their benefits, and how businesses can leverage them for enhanced shipping efficiency.

-

How dry ice pack coolers work in cold chain logistics

-

Best practices for using dry ice coolers during shipping

-

The latest trends in dry ice cooler technology and applications

How Do Dry Ice Pack Coolers Enhance Cold Chain Shipping?

Dry ice pack coolers are crucial for industries involved in the transportation of perishable goods, pharmaceuticals, and other temperature-sensitive items. Their ability to maintain ultra-low temperatures during transit is essential to prevent spoilage, ensure product efficacy, and comply with regulatory requirements.

How Dry Ice Works in Coolers

Dry ice is solid carbon dioxide (CO₂), which sublimates directly from solid to gas at temperatures around -78.5°C (-109.3°F). This process provides a reliable, consistent cooling environment that far exceeds the capabilities of regular ice, making dry ice ideal for long-distance shipping. It does not leave moisture behind, which ensures products stay dry and intact.

Key Benefits:

-

Temperature Control: Dry ice maintains a constant cooling temperature of -78.5°C, far colder than traditional ice.

-

Consistency: The sublimation process provides consistent temperature, reducing risks of fluctuating conditions that could affect the shipment.

-

Moisture-Free: Unlike regular ice, dry ice doesn’t melt into water, which is crucial for products like pharmaceuticals and frozen foods.

Best Practices for Using Dry Ice Pack Coolers

To maximize the effectiveness of dry ice coolers, businesses should follow best practices to ensure safety, compliance, and efficiency.

1. Calculate the Right Amount of Dry Ice

To determine the correct amount of dry ice, consider the shipment’s duration and the size of the cooler. Generally, 5-10 pounds of dry ice are recommended for every 24 hours of transit. However, this amount can vary depending on the type of products and insulation used.

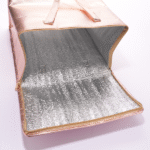

2. Proper Packaging

To prevent temperature fluctuations, always use insulated packaging. Additionally, avoid sealing the cooler too tightly, as CO₂ gas needs to escape safely. This will ensure pressure doesn’t build up inside the cooler.

3. Correct Labeling

Proper labeling is essential for safety and regulatory compliance. Always include the “Carbon Dioxide Solid” label along with handling instructions, ensuring the shipment is treated according to safety regulations.

4. Temperature Monitoring

Using temperature-monitoring devices can help ensure that your products remain within the required temperature range during transit, giving you real-time data on the status of your shipment.

5. Educate Recipients

Educating recipients about safe handling is crucial. Since dry ice sublimates into gas, advise recipients to allow it to dissipate in a well-ventilated area, ensuring safety when they handle the cooler.

Key Benefits of Dry Ice Pack Coolers

| Benefit | Dry Ice Pack Coolers | Impact on Logistics |

|---|---|---|

| Temperature Control | -78.5°C (-109.3°F) | Ensures products remain frozen throughout the shipment |

| Sublimation Process | Direct gas release | Prevents leakage, maintaining a dry environment |

| Extended Shipping Time | 24+ hours | Ideal for long-distance shipments |

| Safety | Proper packaging & labels | Meets regulatory safety standards for hazardous goods |

Practical Tips for Effective Use

Consider Your Shipment Size

For larger shipments, it’s often more effective to use multiple smaller coolers rather than a single large one. This helps with better temperature distribution and reduces the risk of temperature fluctuations.

Combine Cooling Methods

For more precise temperature control, consider using dry ice in combination with gel packs or phase change materials (PCMs). These hybrid cooling systems are particularly beneficial for shipments that require both frozen and refrigerated conditions.

Regularly Check for Leaks

Ensure that coolers are properly sealed to prevent dry ice from escaping prematurely, which can lead to temperature inconsistencies.

Case Study:

A biotech company integrated dry ice pack coolers into their shipping process for temperature-sensitive vaccines. This shift resulted in a 30% reduction in spoilage and enhanced the company’s ability to meet strict delivery windows, improving overall shipping efficiency.

What Are the Latest Trends in Dry Ice Cooler Technology?

As demand for reliable cold chain logistics increases, so does the need for improved dry ice cooler technology. Here are the key trends shaping the industry in 2025:

Eco-Friendly Advancements

Sustainability is a growing priority in cold chain logistics. New eco-friendly insulation materials are reducing the environmental impact of dry ice coolers. The use of biodegradable packaging and recyclable materials in cooler designs is becoming more prevalent.

Temperature Monitoring Innovations

Advancements in IoT (Internet of Things) technology now enable real-time temperature monitoring throughout the entire shipping process. This provides companies with a more granular level of control and ensures that products remain within the required temperature range from departure to delivery.

Enhanced Insulation Materials

The development of high-performance, eco-friendly insulation materials helps dry ice coolers retain cold temperatures for longer periods while also reducing weight. These innovations contribute to overall sustainability in the packaging process.

How Dry Ice Pack Coolers Support Global Shipping Regulations

As global shipping regulations, particularly those governing the transportation of pharmaceuticals and biologics, become stricter, dry ice pack coolers provide businesses with the necessary tools to stay compliant. The coolers’ ability to maintain precise temperatures ensures that shipments meet the required conditions outlined by regulatory bodies such as the FDA and WHO.

Frequently Asked Questions

Q1: How do I calculate the amount of dry ice needed for a shipment?

To calculate dry ice requirements, consider the shipment duration and the size of the cooler. A general guideline is to use 5-10 pounds of dry ice for every 24 hours of transit.

Q2: Is it safe to handle dry ice coolers during transit?

Yes, dry ice is safe to handle when proper precautions are followed. Always wear insulated gloves and ensure the cooler is well-ventilated to allow CO₂ gas to escape.

Q3: Can I use dry ice for shipping food items?

Yes, dry ice is commonly used to ship frozen food, keeping them at the optimal temperature throughout transport. Ensure insulated packaging is used and that the correct labeling is followed.

Summary and Recommendations

Dry ice pack coolers are an essential tool for maintaining cold chain logistics, ensuring safe and efficient shipping of temperature-sensitive goods. By following best practices, staying updated on new technologies, and ensuring compliance with shipping regulations, businesses can maximize the benefits of these coolers for global shipments.

Next Steps:

-

Review your shipping processes: Assess whether dry ice pack coolers can improve your temperature control for specific shipments.

-

Train your team: Provide training on proper dry ice handling and packaging to avoid mishandling.

-

Integrate new technologies: Consider incorporating real-time temperature monitoring systems into your cold chain logistics for enhanced tracking and efficiency.

About Tempk

At Tempk, we specialize in providing advanced cold chain logistics solutions. Our products, including dry ice pack coolers, gel packs, and hybrid systems, are designed to meet the highest industry standards. We are committed to helping businesses optimize their shipping processes while ensuring safety and sustainability.

Contact us today to discover how Tempk’s solutions can streamline your cold chain logistics and help you deliver your products safely and efficiently.