High-Quality Dry Ice Pack Sheets for Efficient Cold Chain Logistics

High-quality dry ice pack sheets are revolutionizing the cold chain logistics industry. These versatile and reliable cooling agents are essential for transporting temperature-sensitive goods across various industries, including pharmaceuticals, food, and biotechnology. Unlike traditional ice packs, dry ice pack sheets provide longer-lasting cooling and prevent moisture damage, which is critical for preserving product quality during transit.

In this article, we’ll explore the features, benefits, and best practices for using high-quality dry ice pack sheets to optimize your cold chain operations in 2025.

-

What are high-quality dry ice pack sheets and how do they work?

-

How do high-quality dry ice pack sheets maintain temperature control during transit?

-

What industries benefit the most from using dry ice pack sheets?

-

How can companies optimize their cold chain logistics with high-quality dry ice pack sheets?

-

What are the safety measures to follow when using dry ice in logistics?

How Do High-Quality Dry Ice Pack Sheets Enhance Cold Chain Logistics?

High-quality dry ice pack sheets are designed to maintain a stable and consistent temperature during the shipment of temperature-sensitive products. These sheets, made from compressed dry ice, sublimate into gas at a controlled rate, ensuring ultra-low temperatures, especially for long-distance shipments. The unique properties of dry ice—sublimating directly from solid to gas—allow these sheets to prevent moisture buildup that can damage sensitive items such as electronics, vaccines, and food products.

Benefits of High-Quality Dry Ice Pack Sheets

-

Longer Duration: High-quality dry ice pack sheets provide consistent cooling for up to 72 hours or more, far surpassing traditional ice packs.

-

Stable Temperature Control: These sheets help maintain a steady temperature, which is essential for preserving the integrity of pharmaceuticals, biological samples, and perishable food items.

-

No Water Byproduct: Since dry ice sublimates into gas, there’s no risk of water damage or spoilage, making them ideal for sensitive products.

-

Eco-Friendly: Produced from recycled CO₂, these dry ice sheets are a sustainable cooling option compared to traditional methods.

Packing Method and Insulation

| Packing Method | Insulation Type | Duration | Best Use Case |

|---|---|---|---|

| Vacuum Sealed Insulated Bags | High | 48-72 hrs | Pharmaceuticals, Biotech |

| Styrofoam Containers | Medium | 24-48 hrs | Perishable Foods, Seafood |

| Insulated Boxes | Very High | 72+ hrs | Electronics, Medical Samples |

Which Industries Benefit the Most from High-Quality Dry Ice Pack Sheets?

High-quality dry ice pack sheets are indispensable in industries that rely on temperature-controlled transport. Some of the key sectors include:

1. Pharmaceutical and Biotechnology

Dry ice pack sheets are essential in the pharmaceutical industry for shipping vaccines, biologics, and medical samples, all of which need ultra-low temperatures to remain viable. For instance, vaccines like the COVID-19 vaccine need to be stored and transported at temperatures as low as -70°C. Dry ice ensures these products stay within their required temperature range during transit, reducing the risk of spoilage.

2. Food and Beverage

The food industry heavily relies on dry ice pack sheets to transport perishable products like seafood, meat, and dairy. These items require precise temperature control to maintain freshness and avoid spoilage. Dry ice pack sheets help preserve the quality of food items by keeping them frozen or chilled for extended periods, even during long shipments.

3. Electronics

Sensitive electronics, such as semiconductors and microchips, require stable, low temperatures to ensure their proper functioning. Dry ice pack sheets help protect these valuable components from heat-related damage during transit, particularly in international shipments with long travel times.

How Can Companies Optimize Cold Chain Logistics with High-Quality Dry Ice Pack Sheets?

Optimizing cold chain logistics is vital for ensuring that products arrive safely and on time. Companies can improve their cold chain operations by incorporating high-quality dry ice pack sheets into their logistics strategy.

Best Practices for Optimizing Cold Chain Logistics:

-

Proper Insulation: Use high-quality insulation materials like vacuum-sealed bags and insulated boxes to maintain cooling efficiency for a longer duration. The better the insulation, the longer the dry ice remains effective.

-

Real-Time Monitoring: Implement temperature monitoring devices to track product temperatures during transit. This ensures that products stay within their required temperature range and reduces the risk of spoilage or degradation.

-

Efficient Routing: Plan shipping routes that minimize transit time and reduce the exposure of products to varying environmental temperatures, ensuring the cold chain remains intact.

Strategies for Effective Use of Dry Ice Pack Sheets:

-

Use advanced insulation materials that enhance temperature retention.

-

Employ temperature sensors that provide real-time data, alerting logistics teams if temperatures deviate.

-

Optimize shipping routes to reduce delays and improve delivery efficiency.

What Safety Measures Should Be Taken When Using Dry Ice?

Handling dry ice requires specific precautions to ensure safety throughout its transportation. Here are some key safety tips:

Safety Guidelines:

-

Ventilation: Dry ice sublimates into carbon dioxide (CO₂), so it’s essential to handle it in well-ventilated areas to avoid CO₂ buildup, which can lead to suffocation.

-

Protective Gear: Wear insulated gloves and goggles when handling dry ice to avoid frostbite or eye irritation.

-

Storage and Transport: Always transport dry ice in well-ventilated containers that allow the CO₂ gas to escape safely, preventing dangerous pressure buildup.

2025 Trends in Dry Ice Pack Sheets for Cold Chain Logistics

In 2025, the dry ice pack sheet industry is evolving with new technologies and trends that focus on sustainability and efficiency. Here are some of the latest developments:

Latest Trends in Dry Ice Usage:

-

IoT Solutions for Temperature Tracking: Real-time temperature sensors allow for immediate alerts if temperatures deviate from the safe range, enhancing cold chain reliability.

-

Sustainable Dry Ice Production: Companies are shifting towards using recycled CO₂ to produce dry ice, reducing overall carbon emissions and improving sustainability.

-

Advanced Packaging: New insulation materials are being developed to increase dry ice efficiency, reduce waste, and extend the duration of cooling during shipment.

Frequently Asked Questions

Q1: How long do high-quality dry ice pack sheets last during transit?

Typically, high-quality dry ice pack sheets last between 24 and 72 hours, depending on insulation, environmental factors, and the amount of dry ice used.

Q2: Is it safe to ship perishable goods with dry ice?

Yes, it is safe to ship perishable goods with dry ice, provided the proper safety measures are followed, including proper packaging and temperature monitoring.

Q3: Can dry ice pack sheets hold temperatures between 2°C and 8°C for 48 hours?

Yes, with the proper sizing and insulation, dry ice pack sheets can maintain temperatures in this range for up to 48 hours.

Conclusion and Recommendations

High-quality dry ice pack sheets are a vital component of cold chain logistics. They offer superior cooling performance, reusability, and flexibility, making them indispensable for industries like pharmaceuticals, food, and electronics. By following best practices and selecting the appropriate sheet types, companies can enhance the reliability of their cold chain operations and ensure the safe transport of temperature-sensitive products.

Next Steps:

-

Integrate high-quality dry ice pack sheets into your cold chain logistics to ensure optimal product protection.

-

Invest in the right insulation, temperature monitoring devices, and route optimization strategies to enhance your logistics operations.

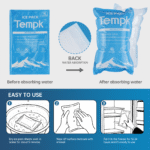

About Tempk

At Tempk, we specialize in cold chain solutions designed to ensure the safety and quality of your products. Our high-quality dry ice solutions are engineered for superior performance and sustainability, optimizing the transportation of sensitive goods while minimizing environmental impact.

Call to Action:

Contact us today to learn more about how our dry ice pack sheets can improve your cold chain logistics and optimize your shipping operations.