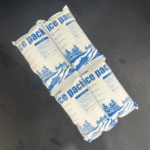

How to Hydrate and Activate Dry Ice Pack Sheets for Effective Cold Chain Solutions

Dry ice pack sheets are vital for maintaining low temperatures during the transportation of temperature-sensitive products, but activating these sheets properly is essential for optimal performance. This guide will take you through the process of hydrating and activating dry ice pack sheets, ensuring that they deliver consistent cooling and perform effectively in your cold chain operations.

-

Proper Hydration and Activation: Learn the step-by-step process to activate dry ice pack sheets for long-lasting cooling.

-

Best Practices for Efficiency: Discover tips to ensure the sheets stay effective during transport and storage.

-

Common Mistakes to Avoid: Avoid errors that could reduce cooling effectiveness or lead to potential damage during shipping.

How to Hydrate Dry Ice Pack Sheets Properly?

Hydrating dry ice pack sheets is an essential process for activating the cooling gel inside, ensuring that the sheets provide consistent cold for longer durations. Proper hydration is the first step to maximizing the effectiveness of these sheets during transport.

Step-by-Step Process for Hydrating Dry Ice Pack Sheets

-

Place the Sheets in Water

Start by submerging the dry ice pack sheets in a container of cold or room-temperature water. Avoid hot water, as it can activate the sheet too quickly and reduce its cooling capacity. Cold water ensures a steady activation process, providing more controlled hydration. -

Wait for Full Absorption

Allow the sheets to sit in the water for about 15-30 minutes. This gives enough time for the polymer in the sheet to absorb the water and expand fully. Make sure the sheets are entirely submerged to ensure complete activation. -

Remove Excess Water

After the sheets have absorbed enough water, gently remove them and allow any excess water to drain off. Excess moisture can lead to leakage or damage during storage or shipping. -

Place the Sheets in a Cooler

Once the sheets are fully hydrated, place them around your temperature-sensitive products inside the cooler. Proper placement ensures that the cooling effect is evenly distributed across the entire shipment.

Practical Example: If you’re shipping sensitive biological samples that require temperatures below 4°C for 48 hours, proper hydration of dry ice pack sheets ensures that the samples remain within the safe temperature range.

Why is Hydrating Dry Ice Pack Sheets Essential?

Proper hydration of dry ice pack sheets optimizes their cooling efficiency, extends the duration of cold release, and ensures the safe transport of temperature-sensitive goods. Hydration activates the polymer, which plays a critical role in maintaining low temperatures for extended periods.

Key Benefits of Hydration:

-

Optimizes Cooling Efficiency: Fully hydrated sheets deliver consistent, effective cooling, preventing temperature fluctuations during transit.

-

Extends Cooling Duration: Hydrated sheets hold cold for a longer period, which is especially useful for extended shipments or storage.

-

Prevents Mishaps: Dry ice pack sheets that are not hydrated properly may underperform, leading to spoiled products or potential safety risks.

| Benefit | Impact | Best Practice |

|---|---|---|

| Optimizes Cooling | Provides steady, reliable cooling | Always hydrate before use |

| Extends Cooling Time | Keeps products within temperature range longer | Use multiple sheets for extended cooling |

| Prevents Mishaps | Reduces risk of temperature fluctuations | Hydrate sheets thoroughly before use |

How Can You Maximize the Effectiveness of Dry Ice Pack Sheets?

To ensure dry ice pack sheets remain effective throughout their use, it’s important to follow some key practices for extended cooling and storage. Here’s how to maximize their performance:

Maximizing Dry Ice Pack Sheet Efficiency

-

Proper Insulation

Ensure the cooler or shipping container is well-insulated. Good insulation ensures that the dry ice pack sheets stay cold for a longer period by minimizing heat exchange with the outside environment. -

Store Sheets in Cool Areas Before Use

Store hydrated sheets in a cool place prior to use. The colder the sheet is before activation, the better it will perform once placed in the shipping container. -

Use Larger Sheets for Longer Shipments

For longer shipments, use larger sheets or multiple sheets to increase the cooling duration. Larger sheets provide more thermal mass, which helps maintain low temperatures for extended periods. -

Limit Opening of the Cooler

Each time the cooler is opened, cold air escapes, reducing the effectiveness of the dry ice pack sheets. Limit the number of times the cooler is opened to maintain a stable temperature inside.

Example: For long-distance shipments of perishable food, using a well-insulated cooler and multiple hydrated dry ice pack sheets ensures that the product stays at the required temperature for up to 72 hours during transit.

Common Mistakes When Activating Dry Ice Pack Sheets and How to Avoid Them

Activating dry ice pack sheets is a simple process, but there are a few common mistakes that can affect performance. Here’s how to avoid them:

-

Using Hot Water

Hot water can cause the sheets to activate too quickly, reducing the cooling duration. Always use cold or room-temperature water for hydration. -

Not Allowing Enough Time for Hydration

Rushing the hydration process can lead to insufficient activation. Always allow the sheets to absorb water for 15-30 minutes to ensure they are fully hydrated. -

Storing Sheets in Hot Environments

Storing dry ice pack sheets in a hot environment before hydration can diminish their cooling effectiveness. Store them in a cool place to maximize their performance.

| Mistake | Impact | Solution |

|---|---|---|

| Using Hot Water | Reduces cooling efficiency | Use cold or room-temperature water |

| Insufficient Hydration | Leads to inadequate cooling | Hydrate for at least 15-30 minutes |

| Storing in Hot Environments | Decreases sheet’s cooling power | Store in a cool environment before use |

The Future of Dry Ice Pack Sheets in Cold Chain Logistics

As cold chain logistics evolve, so does the technology behind dry ice pack sheets. By 2025, new trends such as smart monitoring systems and eco-friendly materials are shaping the future of the cold chain industry.

Emerging Trends:

-

Smart Packaging: Advanced sensors will soon allow temperature and humidity tracking during transport, ensuring that dry ice pack sheets are always functioning at their best.

-

Eco-friendly Refrigerants: New refrigerants and biodegradable packaging materials will help reduce the carbon footprint of shipping cold goods.

-

Customized Solutions: Companies are now developing custom-sized dry ice pack sheets tailored to specific industry needs, improving both cooling efficiency and packaging space.

Market Insight: Businesses that focus on sustainability and advanced cold chain technologies will be better positioned to meet regulatory standards and consumer demand in the coming years.

FAQ

Q1: How long should I hydrate dry ice pack sheets before use?

Hydrate the sheets for at least 15-30 minutes in cold or room-temperature water to ensure proper activation.

Q2: Can dry ice pack sheets be used without hydration?

No, these sheets need to be hydrated before use to activate the cooling gel inside and ensure effective temperature control.

Conclusion

Hydrating dry ice pack sheets properly is essential for ensuring efficient cold chain performance. By following the recommended steps for hydration and activation, you can extend cooling duration, prevent mishaps, and maintain the safety of your temperature-sensitive shipments. Remember to always store sheets in a cool environment, use proper insulation, and limit the number of times you open the cooler to keep temperatures stable.

Next Steps:

-

Hydrate the dry ice pack sheets for at least 15-30 minutes in cold water before use.

-

Ensure proper insulation around the dry ice pack sheets to optimize cooling efficiency.

-

Use multiple sheets for extended cooling during long shipments or storage.

About Tempk

Tempk is a leader in cold chain logistics solutions, specializing in high-quality dry ice pack sheets, temperature monitoring systems, and other cooling products. Our solutions are designed to ensure the safe and efficient transport of temperature-sensitive goods. Reach out to Tempk for reliable, cost-effective cooling solutions for your cold chain needs.