Industrial Dry Ice Packs: How to Choose in 2025?

Updated October 2025. If you move frozen goods at scale, industrial dry ice packs give deep‑cold capacity without meltwater. You get stable temperatures because carbon dioxide sublimates at −78.5 °C and absorbs large heat as it turns to gas. In this guide, you’ll specify pack formats, size by heat load, and lock in safe, auditable SOPs. You’ll leave with templates and tools you can train in minutes.

-

Right‑sizing industrial dry ice packs with a practical, five‑input method

-

Pack‑out templates for pallets, insulated totes, and ULDs with long‑tail keywords

-

Safety and compliance steps for UN1845 labeling and large‑room ventilation

-

Cost, labor, and OEE levers to lower total cost per delivered unit

-

When to switch to PCM or gel, and when to run hybrid layouts

What are industrial dry ice packs and where do they outperform?

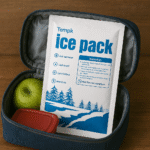

Short answer: Industrial dry ice packs are vented, pre‑formed modules that hold dry ice “snow” or slabs in durable wraps. They spread cold evenly, fit standardized layouts, and scale from totes to pallets. You get quick training, cleaner lines, and fewer cold‑spot claims across long routes.

Explanation you can use: Think of loose pellets as sand, blocks as bricks, and industrial dry ice packs as predictable tiles. Tiles contour to product stacks and maintain an even cold face, which helps with ice cream texture, biologic integrity, and seafood glaze retention. In high‑throughput hubs, tiles cut packing variability and speed audits. They also reduce dust and mess compared with loose fill, especially when you reuse totes and sleeves.

Industrial dry ice pack formats for different lines

Details: You’ll see three main formats on industrial lines: flexible tiles, rigid slabs, and sleeve wraps. Flexible tiles fill corners in totes. Rigid slabs anchor long holds in pallet shippers. Sleeve wraps create a continuous “curtain” that shields warm walls. Match format to your lane, not to habit.

| Format | Handling | Best Use | What it means for you |

|---|---|---|---|

| Flexible tiles | Fast placement; conform to voids | Totes, parcel, ULD corners | Even coverage and quick SOPs |

| Rigid slabs | Fewer pieces; long duration | Pallet shippers, reefer gap‑bridges | Fewer touches; long lanes |

| Sleeve wraps | Continuous side “curtain” | Tall stacks; hot walls | Fewer hot spots; cleaner labels |

Practical tips and advice

-

Totes: Pre‑build tile kits for each SKU family to hit repeatable placement every shift.

-

Pallet shippers: Use slabs at the base and tiles as side curtains to block radiant heat.

-

ULDs: Keep a vent path near the lid and avoid taping over designed vents.

Real case: A seafood exporter standardized sleeve wraps as side curtains plus two slab layers in pallet shippers. Temperature spreads tightened, and rejected loads fell through summer peaks.

How to size industrial dry ice packs for pallets and totes?

Short answer: Start from heat load, not guesswork. Industrial dry ice packs remove heat as CO₂ gas leaves. Estimate hourly heat leak, multiply by route hours, and divide by sublimation energy. Add 10–30% buffer for door openings, staging, and delays.

Why it works: A shipper is a leaky thermos. Leakage depends on area, insulation, ambient, and openings. By treating your pack‑out like a steady heat leak with small disturbances, you get a conservative mass that holds frozen even on hot docks. Then you validate with a lane test and trim excess.

A five‑input sizing method for industrial dry ice packs

Use this practical method. It’s conservative and fits most totes and pallet shippers.

Example: A pallet shipper with A≈3.2 m² and R≈0.5 at 35 °C for 60 h:

Q≈(3.2/0.5)×55≈352 W → m≈(352×60×3.6)/571≈133 kg. Add 15% buffer → ~153 kg total, split as 60% slabs, 40% industrial dry ice packs for side curtains and lid.

| Variable | Typical range | How to estimate | Impact on you |

|---|---|---|---|

| R (EPS 40 mm) | 0.4–0.6 | From spec sheet | Sets baseline mass |

| R (PUR 40–60 mm) | 0.8–1.5 | Supplier or lab test | Cuts CO₂ requirement |

| R (VIP insert) | 2.0–3.0 | Premium liners | Shrinks shipper size |

| A (pallet shipper) | 2.8–3.8 m² | Measure outer box | Higher A → higher mass |

| Buffer% | 10–30% | New lanes → higher | Insurance for delays |

Practical tips and advice

-

Door openings: Add 5–10% extra industrial dry ice packs if dock doors cycle often.

-

Hot walls: Double the side curtain on sun‑facing trailer sides for summer lanes.

-

ULD weight: Balance slab placement to protect center of gravity and handling safety.

Real case: A biologics 3PL added a 10% lid top‑up kit of industrial dry ice packs for a hub prone to ramp delays. Excursions dropped significantly across two months.

Are industrial dry ice packs compliant and safe at scale?

Short answer: Yes—when you vent, label, and train. Industrial dry ice packs must be used with a vent path, UN1845 “Carbon dioxide, solid” marking, and trained staff. Never trap CO₂ in a sealed container; pressure can build.

What to remember: CO₂ displaces oxygen. Use ventilated rooms and vehicles. Apply net mass labels and keep safety data sheets accessible. For air, follow carrier rules for dry ice as a refrigerant. For ground, follow site and regional dangerous goods guidance. Keep loggers and acceptance checks in your SOP.

Industrial dry ice packs compliance checklist

Make this part of your pre‑ship routine.

| Topic | What to do | Where it belongs | Why it matters |

|---|---|---|---|

| Venting | Use vented lids or gaps; never tape vents closed | Shipper design & SOP | Prevents bulging |

| UN1845 label | Mark “Carbon dioxide, solid” + net mass | Exterior panels | Speeds acceptance |

| Documentation | Note dry ice on transport docs when required | Shipment file | Avoids holds |

| PPE & training | Gloves/eye protection; DG awareness | HR/LMS + floor signs | Fewer injuries |

| Storage | Ventilated staging; no sealed rooms | Warehouse plan | Safer CO₂ levels |

Practical tips and advice

-

Shift handoffs: Place a “Contains Dry Ice” tag on all totes left mid‑shift.

-

Fleet rules: For small vans, crack windows and avoid stacking vents against walls.

-

Return cycle: Stage a bin for spent industrial dry ice packs to sublimate safely.

Real case: After adding vent maps and refreshing DG training, a plant reported zero CO₂ alarm events for a full quarter while increasing outbound volume.

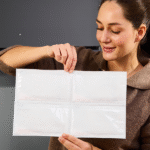

Pack‑out templates: industrial dry ice packs for pharma and food

Short answer: Template the layout, then scale. Industrial dry ice packs shine when you use standardized placements that anyone can repeat under pressure. Pallet, tote, and ULD layouts differ, but the logic is the same: bottom slab, side curtains, top lid layer, and a vent path.

How it helps: Templates reduce cognitive load, cut pack time, and stabilize temperature profiles. You standardize small details—like where the logger goes and which wall gets doubled—so results remain consistent across teams and shifts.

Standardized pack‑outs you can copy

Templates (paste into your SOP):

| Use case | Bottom | Sides | Top | Benefit |

|---|---|---|---|---|

| Long lanes | 2 slabs | Double curtain | Double tiles | Fewer hot spots |

| Short lanes | Dense tiles | Single curtain | Single tiles | Faster pack time |

| Heat waves | 2 slabs | Sleeve wraps | Double tiles | Better buffer |

Practical tips and advice

-

Seafood: Add a moisture barrier between film and cartons; keep industrial dry ice packs outside primary food wrap.

-

Ice cream: Spacer board below lid tiles prevents “frost ring” on pints.

-

Biologics: If freeze‑sensitive, place a thin −21 °C PCM panel against the payload.

Real case: A dessert brand adopted Template P1 with a PCM buffer on products. Texture complaints dropped sharply while hold time extended on hot routes.

When should you use PCM or gel instead of industrial dry ice packs?

Short answer: If you must hold +2 to +8 °C or protect freeze‑sensitive goods, use gel or PCM. Industrial dry ice packs excel at −20 °C and colder. Use hybrids when you need frozen capacity and gentle protection together.

Why hybrids work: PCM “sets the thermostat,” and industrial dry ice packs supply the raw cooling power. The PCM shields delicate items from direct contact while the dry ice handles door openings and long docks.

Hybrid designs with industrial dry ice packs

Starter recipes you can scale:

| Goal | Near product | Outer layer | Outcome |

|---|---|---|---|

| Freeze‑sensitive biologics | PCM −21 °C slab | Industrial dry ice packs | Avoids cold shock |

| Mixed frozen/chilled | Gel +5 °C zone | Industrial dry ice packs zone | Two temps, one shipper |

| Long lane, minimal CO₂ | VIP liner | Slabs + tiles | Smaller shipper, less CO₂ |

Practical tips and advice

-

Chilled only: Skip dry ice entirely; gel or PCM is safer and simpler.

-

Mixed loads: Separate with cardboard baffles so zones do not fight each other.

-

Weight limits: VIP liners often reduce required industrial dry ice packs enough to meet air thresholds.

Real case: A CRO layered −21 °C PCM against vials with industrial dry ice packs outside. The route held range while avoiding over‑freezing during ramp holds.

2025 trends: industrial dry ice packs and automation

Trend overview: Plants want lighter freight, faster training, and cleaner floors. Industrial dry ice packs now come in dust‑reduced wraps, stronger seams, and sizes that match common totes and pallet shippers. Expect greater use of VIP inserts on premium lanes and more wireless loggers. Data‑driven validation replaces guesswork, and standard tile kits reduce pack‑time variance.

Latest advances at a glance

-

Dust‑reduced wraps: Cleaner prep tables and fewer blocked scanners.

-

Modular tile kits: Pre‑counted bags matching specific SKUs and lanes.

-

Sensor workflows: Wireless loggers validate hold time without opening lids.

Market insight: Frozen e‑commerce and pharma trials keep growing. Standardized industrial dry ice packs reduce touch time and help new teams hit spec quickly. VIP liners plus predictable tiles often shrink the shipper one size, cutting freight while maintaining hold time. Plants measure cost per successful delivery, not material cost alone.

Frequently Asked Questions

Q1: How long do industrial dry ice packs last on a pallet?

Hold time depends on insulation, ambient heat, and openings. With PUR or VIP liners, industrial dry ice packs plus slabs often support 48–96 hours. Always lane‑test and add buffer.

Q2: Can I fly with industrial dry ice packs in a ULD?

Yes, when you mark UN1845, show net mass, and keep vents clear. Follow carrier rules for dry ice used as a refrigerant and confirm quantity limits before tender.

Q3: Will industrial dry ice packs damage packaging?

Direct contact can over‑freeze delicate items. Use a liner, spacer board, or thin PCM near the product, then surround with industrial dry ice packs.

Q4: Are industrial dry ice packs food‑contact safe?

Most wraps are not designed for direct contact. Keep packs outside primary packaging unless they are rated food‑contact safe. When unsure, add a barrier film.

Q5: How should we store industrial dry ice packs at the plant?

Use insulated, ventilated bins away from enclosed offices. Rotate stock first‑in, first‑out. Post a one‑page SOP, and keep gloves and eye protection at the station.

Q6: How do we reduce the amount of dry ice used?

Increase insulation R‑value, shrink voids, and double the side curtain on hot walls. These steps usually reduce industrial dry ice packs mass while keeping hold time.

Q7: Do industrial dry ice packs help during short power outages?

Yes. Load tiles near the top shelf of a freezer and keep doors closed. Cold air sinks, stabilizing temperature long enough to ride out short outages.

Q8: Can we reuse industrial dry ice packs?

Dry ice sublimates to gas, so the cold source is single‑use. Reuse the shipper and liners; replenish with new industrial dry ice packs for each cycle.

Q9: What data should we capture during validation?

Start/end temps, peak temp, logger placement, mass of industrial dry ice packs, ambient profile, and open‑door events. Keep graphs with SOPs for audits.

Summary and recommendations

Key takeaways: Use industrial dry ice packs when you need frozen reliability, clean handling, and repeatable layouts. Size by heat load, not guesses. Vent and label for safety and acceptance. Upgrade insulation or use PCM buffers for sensitive goods. Standardize pack‑outs and validate with loggers before scaling.

Action plan:

-

Pick insulation class (EPS/PUR/VIP) for your hottest lane.

-

Run the five‑input calculation, then add 10–30% buffer.

-

Choose a template (P1/T2/U3) and train with a one‑page SOP.

-

Lane‑test with loggers for a week, then lock the mass and placements.

-

Roll out kits and monitor claims, pack time, and delivered cost.

Engagement tools you can deploy today

-

Three‑Question Selector:

-

Is the target ≤ −20 °C? If yes, start with industrial dry ice packs.

-

Lane >48 h or warehouse >30 °C? Add slabs and consider VIP liners.

-

Freeze‑sensitive payloads? Place a thin PCM near product and tiles outside.

-

-

Self‑check rubric (score 0–5 each): Correct mass, ventilation path, insulation class, logger placement, DG labeling. Score ≥20 → ready for scale.

-

Sizing snippet you can paste into your SOP:

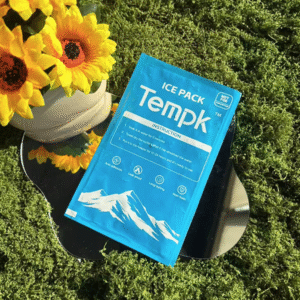

About Tempk

Tempk designs practical cold‑chain systems for plants, exporters, and 3PLs. We integrate industrial dry ice packs, premium liners, and data validation to reduce variability and speed training. Customers see steadier temperatures, fewer claims, and faster pack lines measured by OEE.

Call to action: Contact Tempk for a route‑specific design and a two‑week pilot with templates, kits, and logger analysis.