Shipping temperature-sensitive goods requires optimal cooling to prevent spoilage, especially for pharmaceuticals, frozen foods, and biological samples. Large dry ice packs offer a reliable solution by maintaining ultra-low temperatures during transit. In 2025, the cold chain industry continues to evolve with innovations that enhance the efficiency of these cooling solutions. This article will delve into how large dry ice packs work, their advantages, and best practices for using them effectively.

What Are Large Dry Ice Packs?

Large dry ice packs are blocks of solid carbon dioxide (CO₂) that sublimate directly from solid to gas at a temperature of -78.5°C (-109.3°F). Unlike traditional ice, dry ice leaves no liquid residue, making it ideal for maintaining frozen conditions without the risk of water damage. These packs are commonly used in bulk shipments, ensuring long-lasting cooling for products that require consistent sub-zero temperatures.

Why Choose Large Dry Ice Packs?

Large dry ice packs provide several key advantages over other cooling methods, including gel packs and traditional ice. Here are some reasons why businesses should consider using them for cold chain shipping:

Extended Cooling Duration

Large dry ice packs can maintain extremely low temperatures for up to 72 hours, depending on insulation, ambient temperature, and the amount of dry ice used. This makes them perfect for shipments that require longer transit times.

No Water Residue

Dry ice sublimates directly into gas, leaving no moisture behind. This is crucial for sensitive products like vaccines, seafood, and pharmaceuticals, where water exposure can cause damage.

High Thermal Mass

The larger size of dry ice packs allows for a greater amount of CO₂ to sublimate slowly, providing prolonged cooling with fewer packs needed. This makes them cost-effective for long-distance shipments.

| Feature | Large Dry Ice Packs | Gel Packs |

|---|---|---|

| Temperature Range | Ultra-low (-109.3°F / -78.5°C) | Moderate (32°F to 50°F) |

| Sublimation/ Melting | Sublimates into gas, no residue | Melts into liquid, potential for water damage |

| Handling Safety | Requires gloves and ventilation | Safe to handle without special precautions |

| Reusability | Single-use | Reusable |

| Cost | Higher due to single-use | Lower, especially for reusable types |

Applications in Cold Chain Shipping

1. Pharmaceuticals and Biologics

Large dry ice packs are vital for maintaining the stability of temperature-sensitive medications and biological samples during transit. The ultra-low temperatures they provide help ensure that these products remain within required ranges for efficacy, especially when shipping long distances or internationally.

2. Frozen Food Shipments

Frozen foods, such as ice cream, seafood, and frozen meats, need to remain below freezing temperatures to retain their quality. Dry ice is ideal for these shipments, ensuring they stay frozen for up to 72 hours.

3. Laboratory Samples

Biological and chemical samples require consistent, sub-zero temperatures during transit. Large dry ice packs are used to maintain these conditions, ensuring sample integrity and preventing deterioration.

Best Practices for Using Large Dry Ice Packs

To maximize the efficiency of large dry ice packs, it’s essential to follow these best practices:

Proper Ventilation

Dry ice sublimates into CO₂ gas, which can build up pressure inside packaging. Ensure that shipping containers are ventilated to allow the gas to escape safely, preventing the risk of explosion.

Adequate Insulation

Using high-quality insulation materials like polystyrene foam or vacuum panels slows down the sublimation rate and ensures that the cooling power lasts longer, reducing the need for frequent replenishment.

Correct Labeling

It’s essential to label all packages containing dry ice with the “Dry Ice” or “Carbon Dioxide, Solid” labels and specify the net weight in kilograms. This ensures that carriers follow proper handling protocols and comply with regulatory requirements.

Regulatory Compliance

Following regulations set by agencies such as the DOT, IATA, and IMDG is critical when shipping with dry ice. Packages must be marked appropriately, and certain carriers may have specific weight or packaging restrictions that need to be followed.

Large Dry Ice Packs vs. Gel Packs

While gel packs can be used for certain cold chain applications, they do not offer the same level of performance as large dry ice packs. Gel packs are typically used for refrigeration, with temperatures ranging from 32°F to 50°F, whereas dry ice packs are essential for sub-zero temperatures, ranging from -109.3°F. Gel packs also have a higher risk of melting into liquid, potentially damaging sensitive goods, whereas dry ice sublimates without leaving moisture behind.

How to Calculate and Use a Large Dry Ice Pack

Calculation Guidelines

To calculate the correct amount of dry ice needed, you should follow a simple rule: for every 10-15 lbs of product, plan for 5-10 lbs of dry ice per 24 hours. For example, if your shipment weighs 25 lbs and travels for 2 days, you will need between 20-40 lbs of dry ice.

Packaging Considerations

Ensure that the dry ice is placed on top of the goods within the container to allow for even cooling. The container should be insulated and allow for proper ventilation to release the sublimated CO₂ gas.

Safety and Handling of Large Dry Ice Packs

Protective Gear

Due to the extremely low temperatures of dry ice, it’s essential to handle it with insulated gloves and safety goggles. Never touch dry ice with bare hands to avoid frostbite.

Ventilation Requirements

Ensure that the area where dry ice is stored or used is well-ventilated to prevent CO₂ buildup. In enclosed spaces, high levels of CO₂ can displace oxygen, leading to dizziness, headaches, or suffocation.

Cost and Sustainability Considerations

Cost Factors

While dry ice packs can be more expensive upfront than gel packs, their longer cooling duration and reliability make them cost-effective in the long term. Bulk purchasing and proper insulation can reduce the overall cost of shipping with dry ice.

Sustainability

The dry ice industry is moving towards more sustainable practices, such as using captured CO₂ from industrial processes. This reduces the environmental impact of dry ice production while maintaining its effectiveness for cold chain logistics.

2025 Innovations in Dry Ice Packs

Smart Packaging

The integration of IoT sensors and GPS tracking into dry ice packaging is a growing trend in the cold chain industry. These technologies allow real-time monitoring of the temperature and location of shipments, enhancing visibility and reducing risks during transit.

Eco-Friendly Solutions

As sustainability becomes more important, companies are exploring alternative sources of CO₂ for dry ice production. Captured CO₂ and recyclable insulation materials are part of the ongoing push for greener logistics.

FAQ – Frequently Asked Questions

Q1: How long does a large dry ice pack last?

A large dry ice pack typically lasts between 24–72 hours, depending on the amount used, the insulation, and the external temperature.

Q2: Can I reuse a large dry ice pack?

No, dry ice sublimates directly into gas, leaving no solid residue, so it cannot be reused. However, some reusable cooling solutions like gel packs can be used multiple times.

Q3: What are the packaging and labeling requirements for dry ice shipments?

Dry ice shipments must be labeled with “Dry Ice” or “Carbon Dioxide, Solid,” with the UN 1845 designation, and the net weight of the dry ice must be specified. Packaging should allow CO₂ gas to vent safely.

Conclusion

Large dry ice packs play a vital role in maintaining the safety and integrity of temperature-sensitive shipments. With advancements in technology and packaging, they remain a reliable solution for industries requiring sub-zero cooling, such as pharmaceuticals, food, and biologics. By understanding their advantages, proper handling, and best practices, businesses can enhance their cold chain shipping operations and minimize risks.

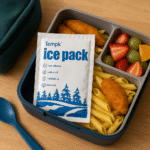

About Tempk

At Tempk, we specialize in providing high-quality cold chain solutions, including large dry ice packs, to meet the diverse needs of our clients. Our products are designed to ensure the safe and efficient transport of temperature-sensitive goods. Contact us today to learn more about our large dry ice packs and how they can enhance your cold chain shipping processes.