In the fast-paced world of cold chain logistics, maintaining the integrity of temperature-sensitive goods during transit is critical. A pack of 12 dry ice pack sheets is a cost-effective and reliable solution to ensure that your products stay at the required temperature. Whether you are shipping food, pharmaceuticals, or chemicals, these dry ice sheets are engineered to deliver consistent cooling for extended periods. In this guide, we will explore how dry ice pack sheets work, their benefits, and the best practices for ensuring the success of your cold chain operations.

What Are Dry Ice Pack Sheets and How Do They Work?

Dry ice pack sheets are made from polymer materials, designed to hold and release cold temperatures. These sheets typically contain a grid of cells filled with supercooled gel or phase change material (PCM), enabling them to maintain temperatures between -12°C and -18°C for extended periods. Unlike traditional ice, dry ice sublimates into carbon dioxide gas without leaving any liquid residue, making it a clean and effective solution for shipping temperature-sensitive goods.

These sheets are available in packs, such as a pack of 12, providing flexibility for different-sized shipments. Once activated, the sheets can maintain cooling for up to 48 hours, depending on factors like ambient temperature and packaging insulation.

How a Pack of 12 Dry Ice Sheets Benefits Your Cold Chain Logistics

1. Consistency and Reliability

A pack of 12 dry ice sheets ensures that your goods are uniformly cooled throughout the entire shipment process. The flexibility of the sheets allows them to be cut or positioned strategically around your products for maximum efficiency.

2. Cost-Effective and Eco-Friendly

Dry ice sheets are reusable in many cases, reducing the need for single-use cooling options like gel packs. This not only cuts down on long-term costs but also supports sustainability initiatives by minimizing waste.

3. Flexibility in Use

Dry ice sheets are versatile. They can be used for various industries, including pharmaceuticals, food, and chemicals, where maintaining specific temperature ranges is essential. The sheets’ flexibility allows them to conform to the shape of the cargo, ensuring optimal temperature control.

4. Ease of Use

Unlike bulky ice packs, dry ice sheets are lightweight and easy to handle. They do not require special refrigeration equipment and are easier to store and transport, making them an ideal choice for cold chain logistics.

How Do You Use a Pack of 12 Dry Ice Sheets?

To ensure optimal performance, it’s crucial to follow the proper handling and placement procedures when using dry ice pack sheets.

Step-by-Step Guide for Using Dry Ice Pack Sheets:

-

Prepare Your Shipping Container:

Begin by pre-chilling your shipping container to ensure that it is at the correct temperature before placing the goods inside. This helps maintain the cold chain for a longer duration. -

Distribute the Sheets Evenly:

When using a pack of 12 dry ice sheets, make sure to evenly distribute the sheets around the product. This ensures that the cold is maintained at all points of contact. -

Seal the Container Properly:

Seal your shipping container tightly to minimize air exchange. This helps preserve the temperature for longer, preventing any rapid sublimation of the dry ice. -

Monitor the Temperature:

For added assurance, consider using temperature loggers or indicators that can monitor the temperature throughout the shipping process. This helps ensure that the goods remain within the desired temperature range.

How Long Do Dry Ice Sheets Last?

The duration of cooling depends on several factors, including the temperature of the surrounding environment, the insulation quality of the container, and the size of the shipment. Typically, a pack of 12 dry ice pack sheets can maintain temperatures for 18 to 48 hours.

Factors Affecting Duration:

-

Environmental Temperature: Hotter climates will cause dry ice to sublimate faster, so additional insulation may be necessary.

-

Insulation Quality: The better insulated the container, the longer the dry ice sheets will last.

Are There Any Risks Involved?

While dry ice sheets are highly effective, there are some risks involved. It’s important to handle dry ice carefully to avoid harm.

Handling Risks:

-

Frostbite Prevention: Always wear gloves or use tongs to handle dry ice, as it can cause severe frostbite if it comes into contact with skin.

-

Ventilation: Never store dry ice in sealed containers. The CO2 gas released during sublimation can build up pressure and cause an explosion.

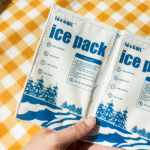

Reusability of Dry Ice Pack Sheets

One of the biggest advantages of using dry ice pack sheets is their reusability. If stored correctly and not exposed to high temperatures, a pack of 12 dry ice sheets can be reused multiple times. This makes them an economical and eco-friendly option for businesses with regular cold chain shipping needs.

Tips for Reusing Dry Ice Sheets:

-

Store dry ice sheets in a cool, dry place when not in use.

-

After each use, check for damage, clean the sheets if necessary, and refreeze them for future use.

Industry-Specific Applications of Dry Ice Sheets

Pharmaceutical Industry:

Dry ice pack sheets are invaluable in the pharmaceutical industry, where the correct temperature is critical for maintaining the efficacy of drugs. They are commonly used for shipping temperature-sensitive medications, including vaccines and insulin.

Food Industry:

For businesses in the food industry, dry ice sheets help preserve freshness by maintaining the required temperatures for products like seafood, meat, and frozen meals. Dry ice ensures that perishables stay at the right temperature throughout the supply chain.

Chemical Industry:

The chemical industry often requires precise temperature control during shipping. Dry ice pack sheets offer a stable, mess-free solution for transporting chemicals that need to remain at low temperatures.

FAQ: Common Questions About Dry Ice Pack Sheets

Q1: Can dry ice pack sheets be reused?

Yes, dry ice sheets can be reused if they are properly stored and not exposed to high temperatures.

Q2: How long do dry ice sheets last during shipment?

The duration varies but typically lasts between 18 to 48 hours, depending on insulation and ambient conditions.

Q3: Are dry ice sheets safe for shipping?

When handled correctly, dry ice sheets are safe. Ensure proper ventilation and protective gear to avoid risks.

Conclusion

A pack of 12 dry ice pack sheets is an essential solution for cold chain shipping in 2025. They are cost-effective, reusable, and versatile, offering consistent cooling for a wide range of industries. By understanding how to use dry ice pack sheets correctly, you can ensure that your temperature-sensitive goods are delivered in optimal condition.

Next Steps:

-

Assess your cold chain needs and determine if dry ice pack sheets are the right solution.

-

Order a pack of 12 dry ice pack sheets to start improving the reliability and efficiency of your shipping operations.