A refrigeration gel pack perishable goods manufacturer can protect freshness when trucks are late and weather turns hot. Your perishables often travel 24–72 hours, and many chilled programs target 2–8°C. A few warm hours can soften texture, dull flavor, and shorten shelf life. This 2026 playbook shows you how to pick the right manufacturer, validate real lanes, and reduce spoilage without overweighting every box.

This article will help you answer:

How a refrigeration gel pack perishable goods manufacturer controls temperature drift in real lanes

Which formats work best for 2–8°C cold chain shipping across food categories

What validated thermal performance testing should look like before you scale

How leak-proof gel pack packaging prevents claims and messy deliveries

How to source bulk gel packs for perishables with fewer quality surprises

Why does a refrigeration gel pack perishable goods manufacturer affect your profit?

A refrigeration gel pack perishable goods manufacturer affects profit because temperature failures create “hidden costs” that never show on a unit price quote. One warm box can trigger refunds, reships, and lost repeat orders. You also lose labor time handling complaints and investigations. The best manufacturers prevent issues before they happen with repeatable performance and clear documentation.

When you treat gel packs like a commodity, you gamble on consistency. When you treat them like engineered components, you reduce exceptions. Your goal is not the coldest possible box. Your goal is the most stable box, across seasons and carriers.

Stable cold vs maximum cold: the key mindset shift

Most perishable programs need stable cold, not maximum cold. That single choice prevents frozen spots and improves arrival quality. Your drafts already highlight this idea, and it is worth keeping as a core principle.

refrigeration gel pack perishab…

| Approach | What it creates | Risk | What it means for you |

|---|---|---|---|

| Maximum cold | Very cold start, fast warm-up | Frozen damage + late warming | More complaints |

| Stable cold | Controlled cooling curve | Lower | More consistent arrivals |

Practical tips and advice

If you ship delicate greens: Avoid direct contact with hard-frozen packs.

If you ship seafood or meat: Use longer-duration packs with higher thermal mass.

If you ship mixed meal kits: Prioritize even coverage, not “one cold corner.”

Real-world case: A shipper reduced complaints after switching from “more packs” to “better placement” and consistent pre-conditioning.

How does a refrigeration gel pack perishable goods manufacturer hit your target range?

A refrigeration gel pack perishable goods manufacturer hits your target range by controlling three things: gel behavior, pack geometry, and sealing consistency. Gel behavior is how the pack absorbs heat over time. Geometry is how cold spreads inside your shipper. Sealing consistency is what prevents leaks and keeps performance stable across batches.

You can think of your shipper like a small house in the sun. Heat pushes in through the roof and walls. A good manufacturer helps you “slow the heat” with predictable cold release and smart placement.

Which gel behaviors work best for 2–8°C cold chain shipping?

Different perishables respond differently to cold. That means the best gel behavior changes by product.

| Perishable category | Common sensitivity | Better gel behavior | Your benefit |

|---|---|---|---|

| Leafy greens | Chilling injury | Gentle curve | Better texture |

| Dairy | Flavor shift | Tight mid-range | Fewer returns |

| Seafood | Spoilage risk | Long hold-time | More consistency |

| Meal kits | Mixed contents | Balanced coverage | Fewer “one item warm” issues |

Practical tips and advice

Ask for time–temperature curves. Curves are better than “hours of cooling” claims.

Standardize pre-conditioning time. Variability often starts in your freezer SOP.

Match pack shape to box shape. A perfect gel pack fails in a bad layout.

Real-world case: A shipper improved arrival quality after replacing random placement with a repeatable packout diagram.

What should you request from a refrigeration gel pack perishable goods manufacturer?

You should request proof of consistency: gel set point range, seal strength, lot traceability, and test summaries that match your lanes. If a refrigeration gel pack perishable goods manufacturer cannot show repeatable data, you are buying uncertainty. Your drafts already emphasize this “ask for proof” approach, and it is a strong 2026 standard.

refrigeration gel pack perishab…

Here is a simple “request list” you can copy into a supplier email.

Gel formulation range (target temperature band)

Pack dimensions and weight tolerance (batch consistency)

Film type and thickness (puncture resistance)

Seal method and seal width (leak control)

Lot coding and traceability rules

Storage guidance (freezer time and temperature)

Test method summary for validated thermal performance testing

Quick manufacturer capability check: “Do they behave like engineers?”

Use this as a fast filter during calls.

| Question you ask | What a strong answer sounds like | Red flag answer | Meaning for you |

|---|---|---|---|

| “How do you control batch variation?” | Weight tolerance + QC sampling | “It’s usually fine” | Predictability |

| “What fails most often in the field?” | Seal + corner puncture details | “We never see failures” | Honesty |

| “How do you support validation?” | Lane plan + logger advice | “Just use more packs” | Cost risk |

Practical tips and advice

Request retention samples. Store a few packs from each lot for investigations.

Ask for change control. You want notice before materials or factories change.

Set acceptance rules early. Seal integrity and weight tolerance should be written.

Real-world case: A shipper traced a leak spike quickly because lot coding was clear.

Which refrigeration gel pack perishable goods manufacturer formats should you choose?

A refrigeration gel pack perishable goods manufacturer should offer formats that match your product density, airflow, and transit time. Flat packs cool evenly across surfaces. Brick packs provide longer hold time. Wrap or contour packs help with irregular loads.

Your drafts include a strong “format selection” section, and it is one of the most practical parts to keep—while tightening the language and adding decision support.

refrigeration gel pack perishab…

Format decision tool: pick the shape in 30 seconds

Choose the first statement that matches your box.

My box is shallow and wide → Start with flat packs for even coverage.

My box is tall or heavy → Add bricks for longer hold time.

My products shift during transit → Consider wrap packs or side panels.

My product bruises easily → Avoid direct contact and use a buffer layer.

| Format | Best for | Typical mistake | What it means for you |

|---|---|---|---|

| Flat packs | Produce, meal kits | Stacking in one corner | Hot spots |

| Brick packs | Seafood, meat | Overfreezing delicate items | Texture damage |

| Wrap packs | Irregular loads | Blocking airflow | Uneven cooling |

Practical tips and advice

Short transit (<24h): Flat packs often reduce weight and cost.

Long transit (48–72h): Bricks often hold cold longer with fewer units.

Mixed loads: Combine formats for coverage and endurance.

Real-world case: A shipper improved results by combining bricks for endurance and flat packs for coverage.

How do you validate a refrigeration gel pack perishable goods manufacturer before scaling?

Validation proves that your refrigeration gel pack perishable goods manufacturer works in your box, your lane, and your season. Lab claims do not equal delivery performance. Validation reduces trial-and-error during peak season and protects your brand.

Your drafts provide a solid HowTo plan and emphasize repeat runs and logger placement. That is exactly what modern cold chain programs do.

refrigeration gel pack perishab…

HowTo: a validation plan you can repeat every season

Define your target range (example: 2–8°C) and maximum time out of range.

Choose worst-case profiles (summer heat, winter cold, long dwell times).

Pack exactly like production (same insulation, tape, and product order).

Place 2–4 temperature loggers near edges and the top corner.

Run at least three repeats per lane and season to confirm repeatability.

Review curves with the manufacturer and adjust placement before adding packs.

| Validation step | What you measure | Pass/Fail rule | Your benefit |

|---|---|---|---|

| Pre-conditioning | Starting pack temp | Within SOP band | Lower variability |

| Lane simulation | Internal temp curve | Stays in range | Predictable arrival |

| Repeatability | Run-to-run spread | Small differences | Fewer exceptions |

Practical tips and advice

Place one logger near the top edge. Heat often enters from the top first.

Photograph every packout. Photos speed root-cause analysis later.

Write acceptance criteria. “Looks okay” is not an acceptance standard.

Real-world case: A shipper discovered the warmest point was a top corner and fixed it with placement, not weight.

How do you prevent leaks with a refrigeration gel pack perishable goods manufacturer?

Leak prevention starts with film choice, seal quality, and edge protection. Leaks cost money twice. They damage product and they damage trust. A refrigeration gel pack perishable goods manufacturer should prove leak resistance, not just promise it.

Leak-proof gel pack packaging tests you should require

| Failure mode | Typical cause | Test to request | What it means for you |

|---|---|---|---|

| Seal split | Weak sealing process | Seal burst + compression | Fewer messy claims |

| Corner puncture | Sharp corrugate edges | Edge puncture test | Cleaner deliveries |

| Film cracking | Deep freeze cycles | Freeze–thaw cycling | Better durability |

Practical tips and advice

Use edge guards in tall boxes. Corners puncture packs more than you expect.

Avoid overfilling packs. Overfilled packs stress seals under pressure.

Adopt a “leak zero” rule for ready-to-eat shipments and premium branding.

Real-world case: A shipper reduced leaks after using wider seals and adding corner protection.

How do you right-size packs without overweighting every shipment?

Right-sizing is about placement and thermal mass, not maximum quantity. Many teams add gel packs when problems appear. That can work, but it is often the most expensive fix. A refrigeration gel pack perishable goods manufacturer should help you solve hot spots with layout first.

Your drafts include a useful “starter estimator” and adjustment rules. We will keep the idea but improve clarity and add a cost lens.

refrigeration gel pack perishab…

Interactive estimator: where should you start?

Start with box size, then adjust by risk. Validate after.

Small shipper (under 10L): start with 2–4 flat packs

Medium shipper (10–25L): start with 4–8 mixed packs

Large shipper (25L+): start with bricks + side coverage

Now adjust:

Add +25% for 48–72 hour lanes.

Add +25% for summer peaks and doorstep heat.

Reduce -15% if you have strong insulation and fast delivery.

| Lane factor | Low | Medium | High | What it means for you |

|---|---|---|---|---|

| Transit time | <24h | 24–48h | 48–72h | Longer lanes need endurance |

| Heat exposure | Cool | Warm | Hot | Hot routes need stability |

| Handling | Smooth | Mixed | Rough | Rough lanes need durability |

Practical tips and advice

Fix placement first. It often solves uneven cooling without adding weight.

Avoid direct contact for sensitive goods. A buffer sheet prevents cold burns.

Request a packout diagram. A good manufacturer provides one consistently.

Real-world case: A shipper reduced freight cost after improving side-wall coverage and removing extra packs.

How do you evaluate a refrigeration gel pack perishable goods manufacturer with a scorecard?

A scorecard protects you from choosing based on unit price alone. The cheapest refrigeration gel pack perishable goods manufacturer can become the most expensive after spoilage, refunds, and reships. A scorecard makes trade-offs visible and repeatable across your team.

Your drafts include a strong scorecard idea and a practical reminder: separate thermal testing from distribution hazard testing. Keep that distinction in 2026.

refrigeration gel pack perishab…

Supplier scorecard (copy and use)

Score each item from 1–5.

| Category | What “good” looks like | Your score | What it means for you |

|---|---|---|---|

| Thermal proof | Repeatable curves + reports | Predictable arrival | |

| Leak resistance | Compression + puncture confidence | Cleaner deliveries | |

| Traceability | Lot-level tracking | Faster investigations | |

| Capacity | Predictable lead times | Peak-season stability | |

| Support | Packout diagrams + validation help | Faster improvements |

Practical tips and advice

Ask for three lane references by lane type, not by brand name.

Test your worst season first. Summer failures are more expensive to fix later.

Require change control. Material changes without notice can break performance.

Real-world case: A shipper chose a higher-priced supplier after scorecard results showed fewer failures and better repeatability.

2026 latest developments and trends in refrigeration gel packs

In 2026, buyers expect a refrigeration gel pack perishable goods manufacturer to deliver predictability, not just cold. Programs are shifting toward tighter temperature targeting, stronger durability, and clearer documentation. Many shippers now treat gel packs as engineered components paired with written SOPs.

Latest progress snapshot

Narrower temperature targeting: More options tuned for specific perishable needs.

Higher durability films: Better puncture and seal performance in tough last-mile handling.

Packout optimization support: More manufacturers helping reduce excess gel use.

Market insight

Perishable brands are under pressure to cut waste and protect trust. That rewards manufacturers who help you validate lanes and prevent leaks. It also pushes teams to build “summer SOPs” and “winter SOPs” instead of one generic plan.

Internal linking suggestions (no external links)

Use these as internal page ideas and site navigation anchors:

Perishable cold chain packout checklist — /perishable-cold-chain-packout-checklist

2–8°C shipping validation guide — /2-8c-shipping-validation-guide

Leak-proof gel pack packaging tests — /leak-proof-gel-pack-packaging-tests

Bulk gel packs for perishables buying guide — /bulk-gel-packs-for-perishables-buying-guide

Temperature logger placement tips — /temperature-logger-placement-tips

Frequently Asked Questions

Q1: What should a refrigeration gel pack perishable goods manufacturer prove first?

They should prove repeatable thermal performance in your target range and lane conditions. Ask for curves and repeat tests. Validate in worst-case seasons.

Q2: Why do boxes arrive warm even with more gel packs?

You may have hot spots from poor placement or blocked airflow. Fix placement first. Then adjust thermal mass and gel quantity based on validation data.

Q3: What is the most common failure with gel packs for perishables?

Leaks and uneven cooling are the most common. Prevent leaks with stronger seals and edge protection. Prevent uneven cooling with consistent packout diagrams.

Q4: Can a refrigeration gel pack perishable goods manufacturer customize pack shape?

Yes. Many offer flat packs, bricks, and custom formats. Custom shape helps when your box geometry creates predictable hot spots.

Q5: Are reusable gel packs realistic for perishable shipping?

They can work in closed-loop lanes with reliable returns. If returns are inconsistent, disposable or hybrid models often perform better operationally.

Q6: What documents should I keep for audits and claims?

Keep packout photos, lane conditions, logger data, and lot codes. These items help you prove control and fix issues quickly.

Summary and recommendations

A refrigeration gel pack perishable goods manufacturer is not just a supplier. It is a risk-control partner for your cold chain. Focus on stable cold behavior, leak resistance, and repeatable validation. Use a scorecard to avoid price-only decisions. Standardize your packout into SOPs and re-test when lanes or seasons change.

Action plan (CTA)

Write your target range, lane time, and worst-case season.

Request curves, QC checks, and leak resistance evidence from the manufacturer.

Run three validation repeats with loggers and packout photos.

Fix placement before increasing gel quantity.

Lock the winning packout into a simple SOP for your team.

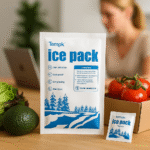

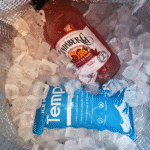

About Tempk

At Tempk, we support perishable cold chain shipping with engineered refrigeration gel packs and packout guidance. We focus on consistent sealing, stable thermal behavior, and validation-friendly documentation. We also help you reduce unnecessary pack weight by improving placement and repeatability.

Next step: Share your box size, product type, target range, lane time, and hottest season. We will outline a validation-first plan you can standardize across shipments.