Shipping Kit Dry Ice Pack – Essential for Safe and Efficient Cold Chain Logistics

Introduction

When shipping perishable goods, maintaining the integrity of the cold chain is essential to ensure freshness. A shipping kit dry ice pack is a critical solution for businesses needing to ship temperature-sensitive items like food, pharmaceuticals, or biological samples. This guide will explain why dry ice packs are indispensable, how to choose the right one for your needs, and the best practices for ensuring safe and compliant cold chain shipping.

-

What is a shipping kit dry ice pack and how does it work?

-

Why is it crucial for cold chain shipping?

-

How to choose the right dry ice pack for your shipping kit?

-

Best practices for handling and shipping with dry ice packs

-

2025 trends in dry ice shipping and innovations

What is a Shipping Kit Dry Ice Pack and How Does It Work?

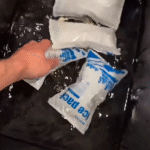

A shipping kit dry ice pack is a cooling solution designed for shipping perishable items at a consistently low temperature. Dry ice, the solid form of carbon dioxide (CO2), sublimates at -78.5°C (-109.3°F), absorbing heat from its surroundings. This process helps maintain the contents of the shipping kit at the required low temperatures throughout the transit period, ensuring product safety and freshness.

Why is Dry Ice Effective for Shipping?

Unlike traditional ice packs that melt and release water, dry ice sublimates directly into gas, eliminating any risk of water leakage. This makes it ideal for items that could be damaged by moisture, such as electronics, pharmaceuticals, and food. Dry ice is also effective for long shipments, providing consistent cooling over extended periods.

Why is a Shipping Kit Dry Ice Pack Crucial for Cold Chain Shipping?

For perishable goods like meat, seafood, pharmaceuticals, or vaccines, maintaining consistent cold temperatures is paramount. Temperature fluctuations can lead to spoilage, loss of potency, or damage to fragile items. Dry ice packs provide several advantages in these situations:

-

Consistent Low Temperature: Dry ice keeps shipments frozen or at the required temperature for an extended time, preventing bacterial growth and spoilage.

-

No Meltwater: Since dry ice sublimates into gas, there is no water residue that could damage the contents.

-

Longer Cooling Duration: Dry ice packs are ideal for long shipments, including international shipping, offering sustained cooling for up to 72 hours.

How to Choose the Right Dry Ice Pack for Your Shipping Kit?

Selecting the right dry ice pack involves several factors. Consider these key points to optimize your cold chain logistics:

1. Shipping Duration

-

For short shipments (under 24 hours), a small dry ice pack (5 lbs) will suffice.

-

For longer shipments (over 48 hours), opt for larger packs or additional dry ice to ensure consistent cooling.

2. Temperature Requirements

-

Products that require freezing temperatures (such as meat and vaccines) need more dry ice to maintain their quality throughout the shipment.

-

Refrigerated products can often be shipped using gel packs or phase change materials (PCMs), but dry ice is still preferred for frozen items.

3. Shipment Size

-

Larger shipments or bulk goods need more dry ice. Ensure the dry ice pack size matches the size of the shipment.

4. Packaging Type

-

Ensure the shipping container is insulated and vented to allow the CO2 gas to escape safely during sublimation.

5. Shipping Regulations

-

Shipping dry ice is subject to regulations that limit its weight per package (typically 5.5 lbs on passenger aircraft). Always check your carrier’s rules.

Dry Ice Pack Types

| Pack Type | Weight | Cooling Duration | Ideal for | Key Benefits |

|---|---|---|---|---|

| Standard Dry Ice Pack | 5 lbs | 24 hours | Short shipments | Easy handling, ideal for overnight shipping |

| Heavy-Duty Dry Ice Pack | 10 lbs | 48-72 hours | Long transit, large shipments | Longer cooling duration, large shipment compatibility |

| Eco-friendly Dry Ice Pack | 5 lbs | 24 hours | Sensitive products | Sustainable packaging, environmentally friendly |

Best Practices for Shipping with Dry Ice Packs

1. Proper Packaging and Insulation

Always use insulated containers to maintain low temperatures. Dry ice should be in direct contact with the products to ensure consistent cooling.

2. Correct Placement of Dry Ice

Place dry ice at the bottom of the box to prevent direct contact with sensitive items. Ensure air circulation to avoid rapid sublimation.

3. Handling and Safety Guidelines

-

Wear gloves when handling dry ice to prevent frostbite.

-

Ensure proper labeling of the package, as dry ice is considered hazardous material.

4. Ventilation is Key

Dry ice releases CO2 gas, so your packaging must allow for ventilation to avoid dangerous pressure buildup.

2025 Trends in Dry Ice Shipping

The Evolution of Dry Ice Shipping Technology

In 2025, cold chain logistics continue to innovate with technologies such as smart packaging, real-time temperature tracking, and eco-friendly materials. These trends improve shipment monitoring and reduce environmental impact.

Latest Developments

-

Smart Sensors and Data Loggers: Real-time temperature and CO2 monitoring ensures the integrity of the cold chain, enhancing reliability.

-

Sustainability: With increasing demand for eco-friendly practices, innovations like recyclable packaging and biodegradable materials are being integrated into dry ice shipping kits.

-

Automation: Automated packing and shipping systems are improving efficiency and reducing human error in the cold chain logistics process.

FAQs About Shipping Kit Dry Ice Packs

Q1: How much dry ice do I need for a 24-hour shipment?

For a 24-hour shipment, approximately 5 lbs of dry ice is typically sufficient, depending on shipment size and temperature needs.

Q2: Is dry ice safe for shipping food products?

Yes, dry ice is safe for shipping food products, as long as the packaging is insulated and vented properly.

Q3: Can I ship dry ice internationally?

Yes, but international shipments require adherence to regulations, including proper labeling and weight limits.

Conclusion and Recommendations

Dry ice packs are essential for ensuring the safe transportation of temperature-sensitive products. By selecting the right dry ice pack and following best practices, you can optimize your cold chain shipping and minimize spoilage. Ensure compliance with regulations and stay informed about the latest trends in shipping technologies to enhance your logistics operations.

Next Steps for Your Business

-

Review your cold chain practices and integrate dry ice into your shipping kits.

-

Consult with professionals to ensure regulatory compliance.

-

Explore sustainable and smart packaging options to improve operational efficiency.

About Tempk

At Tempk, we provide cutting-edge cold chain solutions for businesses that require reliable shipping of temperature-sensitive products. Our dry ice packs and insulated shipping kits are designed to meet industry regulations, ensuring product safety and reducing waste. Contact us today for expert advice on optimizing your shipping solutions.