Thermal EPP Cooler Box Premium: Worth It in 2025?

A thermal EPP cooler box premium is worth it when your routes face delays, frequent opening, or rough handling. You are not buying “a box.” You are buying stable temperature time during real-life chaos, like traffic and handoffs. Many EPP grades are reported around λ 0.035–0.041 W/mK, and common EPP density ranges are widely described across grades.

This article will answer for you:

-

How a thermal EPP cooler box premium for food delivery protects quality on real routes

thermal EPP cooler box premium

-

What drives premium EPP cooler box temperature retention time (and what doesn’t)

thermal EPP cooler box premium

-

How to choose a thermal EPP cooler box premium for seafood without overpaying

thermal EPP cooler box premium

-

How to run a reusable thermal EPP box for last-mile logistics with fewer losses

thermal EPP cooler box premium

-

How to handle thermal EPP cooler box premium cleaning and sanitizing fast and safely

thermal EPP cooler box premium

What is a thermal EPP cooler box premium, in simple terms?

A thermal EPP cooler box premium is a reusable insulated container made from expanded polypropylene (EPP) that’s built to perform under repeated stress. “Premium” usually means stronger construction, better lid sealing, consistent walls, and design details that reduce heat leaks at corners and handles.

thermal EPP cooler box premium

Think of it like this: a basic cooler is a jacket on a mild day. A thermal EPP cooler box premium is a winter coat with a zipper and cuffs.

thermal EPP cooler box premium

Premium performance is not only “thicker walls.” It also depends on lid fit, corner strength, stacking stability, and how clean the inside stays.

thermal EPP cooler box premium

That matters because your operation is not gentle. Boxes get dropped, dragged, and stacked every day.

thermal EPP cooler box premium

Premium features that actually change outcomes

Premium designs focus on repeatability: the lid closes the same way every time. Corners resist dents that become cracks later. Stacking lips reduce wobble in vans and hubs. This is why EPP is chosen in daily logistics where impact resistance matters.

thermal EPP cooler box premium

If your lids feel “loose,” the seal is your hidden problem, not wall thickness.

thermal EPP cooler box premium

| What “premium” changes | Basic insulated box | Thermal EPP cooler box premium | Practical meaning for you |

|---|---|---|---|

| Lid interface | Inconsistent closure | Firm, repeatable seal | Fewer “random warm” complaints |

| Corners/handles | Crack risk rises fast | Better impact tolerance | Fewer replacements and downtime |

| Stacking | Rocking and slipping | Stable stacking geometry | Safer hubs and faster loading |

| Cleanability | Stains and odor linger | Easier wipe + dry routine | Better hygiene confidence |

Practical tips you can use today

-

Loose lids: add a “10-second lid check” at dispatch before the van door closes.

thermal EPP cooler box premium

-

Cracked corners: upgrade corner geometry before you add more coolant.

thermal EPP cooler box premium

-

Stack failures: standardize one box footprint with reliable stacking lips.

Real case: A last-mile food team cut “arrived warm” complaints after standardizing one thermal EPP cooler box premium size and enforcing a simple closure check at dispatch.

thermal EPP cooler box premium

How does a thermal EPP cooler box premium improve temperature retention time?

A thermal EPP cooler box premium improves hold time by reducing heat leaks and slowing temperature rise, especially at the lid seam. In real routes, heat enters through the lid gap most often, then through corners and edges over time.

thermal EPP cooler box premium

Frequent opening and “hot loading” also crush your time cushion fast.

thermal EPP cooler box premium

If your product starts warm, even the best box struggles.

thermal EPP cooler box premium

The big win is not magic insulation. The win is fewer small mistakes that add up. Your team can control four drivers without becoming engineers.

thermal EPP cooler box premium

The 4 drivers you can control in one shift

-

Starting temperature: pre-chill product and coolant before pack-out.

thermal EPP cooler box premium

-

Seal quality: a reliable lid closure can matter more than thicker walls.

thermal EPP cooler box premium

-

Load pattern: big air gaps behave like “mini ovens” inside the box.

thermal EPP cooler box premium

-

Open-time discipline: every opening is like opening your fridge in summer.

thermal EPP cooler box premium

| Driver | What helps most | What hurts most | Practical meaning for you |

|---|---|---|---|

| Starting temp | Pre-chill product | Loading warm items | Shorter safe time window

thermal EPP cooler box premium |

| Lid seal | Firm, consistent closure | Warped lids | Sudden temperature spikes

thermal EPP cooler box premium |

| Packing method | Coolant around critical zones | Big air pockets | Uneven product temperatures

thermal EPP cooler box premium |

| Opening time | Short, planned access | Frequent full opening | Faster drift and more complaints |

Practical tips and suggestions

-

Hot dispatch areas: stage closed boxes in a cooler spot before final loading.

thermal EPP cooler box premium

-

Multi-drop routes: use a “top-layer access plan” to avoid full unpacking.

-

Long routes: set a simple rule: “re-close within 20 seconds.”

Real case: A seafood shipper improved consistency by placing coolant near the “heat entry side” (often the lid/top) and reducing air space with dividers.

thermal EPP cooler box premium

How do you choose a thermal EPP cooler box premium without overpaying?

You avoid overpaying when you match the thermal EPP cooler box premium to your route reality, not your worst imagination. The right choice depends on transit time, ambient exposure, how often drivers open the lid, stacking pressure, and reuse cycles.

thermal EPP cooler box premium

Overpaying usually happens when you buy premium features you never use. Underbuying happens when one failure costs more than the box.

thermal EPP cooler box premium

A “fit” purchase is calm to operate. Packing becomes repeatable and training gets faster. That is often the real premium benefit in 2025 operations.

thermal EPP cooler box premium

Fit-for-Route decision tool (interactive)

Answer “Yes” or “No.” Count your “Yes” answers.

-

Do you deliver over 2 hours regularly?

thermal EPP cooler box premium

-

Do delays happen weekly (traffic, missed handoff)?

thermal EPP cooler box premium

-

Do drivers open the box more than 3 times per route?

thermal EPP cooler box premium

-

Do boxes get stacked in vans or hubs?

thermal EPP cooler box premium

-

Do you reuse boxes in a pooling loop?

thermal EPP cooler box premium

Score → recommendation

-

0–1 Yes: basic EPP may be enough (focus on process).

thermal EPP cooler box premium

-

2–3 Yes: thermal EPP cooler box premium is usually justified.

thermal EPP cooler box premium

-

4–5 Yes: premium + lane-validated pack-out + monitoring is the safer play.

thermal EPP cooler box premium

| Buying question | If “Yes” | What to prioritize | Practical meaning for you |

|---|---|---|---|

| Many openings | Heat enters repeatedly | Lid seal + fast closure | Fewer warm spikes |

| Heavy stacking | Pressure damage risk | Corner strength + lips | Fewer collapses |

| High reuse | Cost per trip matters | Cleanability + ID-ready | Better ROI stability |

| Delay-prone lanes | Stress is normal | Validation + lane kit | Fewer surprise failures |

Practical tips and suggestions

-

Small operators: start with one “workhorse” size and scale after 30 days.

thermal EPP cooler box premium

-

High volume: standardize sizes to cut training time and packing errors.

thermal EPP cooler box premium

-

Pooling: pick a design that supports scanning and clear labeling.

thermal EPP cooler box premium

Real case: One delivery brand spent less by buying fewer premium boxes, then improving pre-chill and lid discipline to outperform “more boxes.”

thermal EPP cooler box premium

How should you pack a thermal EPP cooler box premium for food delivery?

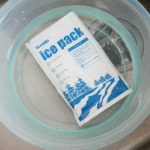

A thermal EPP cooler box premium performs best when you pack it like a “cold sandwich”: coolant, product, coolant, minimal air gaps, fast close. Tight packing slows drift because air space accelerates warming inside.

thermal EPP cooler box premium

Most failures come from empty space and repeated reopening. The box can’t save a messy pack-out.

thermal EPP cooler box premium

Use photo-based pack-out maps so the “right way” is the easiest way. This is why visual SOPs outperform long manuals in 2025 operations.

thermal EPP cooler box premium

If you need help building standard maps, start with Pack-out SOP for reusable shippers.

thermal EPP cooler box premium

3 pack-out maps you can teach in 10 minutes

Pick one map per “lane,” then lock it.

| Lane | Coolant option | Placement rule | Practical meaning for you |

|---|---|---|---|

| Controlled ambient | Mild buffer packs / PCM | Top + hottest side | Protects against heat spikes |

| 2–8°C chilled | Gel packs or setpoint PCM | Sides + top, payload centered | More even temps |

| Frozen | Frozen coolant strategy | Strong buffering, fewer opens | Prevents thaw cycles |

Practical tips and suggestions

-

Hot kitchens: close boxes away from ovens and steam before staging.

thermal EPP cooler box premium

-

Multi-order vans: assign each box a “no-open until stop” rule.

-

Rush dispatch: do a “push corners + center” lid check in 10 seconds.

Real case: A meal-kit team reduced temperature variability by adding dividers, making correct packing fast and repeatable.

thermal EPP cooler box premium

How do you validate a thermal EPP cooler box premium in 2025?

A thermal EPP cooler box premium becomes credible when you validate it against realistic temperature profiles and document pass/fail criteria. ISTA-style thermal standards are widely used to compare insulated shipper performance, and 7E profiles are described as newer testing profiles built from real-world lane data.

thermal EPP cooler box premium

Validation doesn’t need to be complicated. It needs to be repeatable and aligned to your worst lanes.

thermal EPP cooler box premium

Start with three tests: hot-season worst lane, cold exposure, and your normal volume lane. That gives you honest coverage in about two weeks.

thermal EPP cooler box premium

If you want a ready format, use Thermal testing plan template.

thermal EPP cooler box premium

Simple 3-test validation plan (you can run in two weeks)

| Test | When to run | What to watch | Practical meaning for you |

|---|---|---|---|

| Hot profile | Worst summer lane

thermal EPP cooler box premium |

Peak temperature | Finds hidden lid-seam leaks |

| Cold profile | Winter or cold staging

thermal EPP cooler box premium |

Overcooling risk | Prevents “too cold” damage |

| Normal lane | Your main volume route

thermal EPP cooler box premium |

Consistency | Confirms daily repeatability |

Practical tips and suggestions

-

Set acceptance limits before you test. Don’t “reinterpret” after failure.

thermal EPP cooler box premium

-

Validate the system, not the box alone. Box + coolant + payload is the truth.

thermal EPP cooler box premium

-

Change one variable at a time (coolant mass, placement, insert, lid fit).

Real case: One company stopped arguing about “box quality” after validation. The data showed hot staging time was the real root cause, not insulation thickness.

thermal EPP cooler box premium

How do you run thermal EPP cooler box premium cleaning and sanitizing for reuse?

Thermal EPP cooler box premium cleaning and sanitizing works when you treat drying as the final quality step, not an afterthought. Wet stacking drives odor, hygiene concerns, and performance decline over time.

High-volume teams win by making cleaning simple and consistent. A drying rack station often prevents most reuse failures.

thermal EPP cooler box premium

The fastest programs use liners to reduce mess, then focus on seam areas and full drying. Your goal is “clean, sanitized, dry, and seal-checked.”

thermal EPP cooler box premium

For a full workflow, use.

thermal EPP cooler box premium

The “No wet boxes in storage” rule (the premium protector)

| Step | What “done” looks like | What goes wrong | Practical meaning for you |

|---|---|---|---|

| Wash | No visible residue

thermal EPP cooler box premium |

Rushed wipe only | Odor and staining rise |

| Sanitize | Correct contact time

thermal EPP cooler box premium |

Immediate wipe-off | Hygiene confidence drops |

| Dry | No trapped moisture

thermal EPP cooler box premium |

Stacked wet | Shorter box life |

Practical tips and suggestions

-

High volume: build a drying rack station to prevent wet stacking.

thermal EPP cooler box premium

-

Fast turnarounds: use liners to reduce cleaning time.

thermal EPP cooler box premium

-

Training line: “Clean is not enough—dry is the finish line.”

thermal EPP cooler box premium

Real case: A hub improved reuse quality after adding one rule: “No wet boxes in storage,” enforced with a simple supervisor walk-by.

thermal EPP cooler box premium

How do you measure ROI for a thermal EPP cooler box premium?

ROI for a thermal EPP cooler box premium can be measured with three numbers: cost of failure, frequency of failures, and reuse cycles. If premium reduces complaints or damage even modestly, savings add up fast.

thermal EPP cooler box premium

You do not need complex spreadsheets to start. You need a 30-day pilot and honest tracking.

thermal EPP cooler box premium

Track deliveries using the thermal EPP cooler box premium, temperature-related complaints, refunds or reships, and damaged boxes replaced.

thermal EPP cooler box premium

Then compare the pilot routes to your baseline routes with the same products and SOP.

thermal EPP cooler box premium

ROI mini-calculator (interactive)

Fill in the blanks:

-

Failed-delivery cost = $_____ per incident (refund + reship + labor)

thermal EPP cooler box premium

-

Failures per month (baseline) = _____

-

Failures per month (pilot) = _____

-

Savings per month = (baseline − pilot) × failed-delivery cost

-

Replacement savings = baseline box replacements − pilot replacements

thermal EPP cooler box premium

| ROI input | What to track | Why it matters | Practical meaning for you |

|---|---|---|---|

| Complaints | Count per week

thermal EPP cooler box premium |

Quality signal | Measures stability |

| Replacements | Boxes/month

thermal EPP cooler box premium |

Durability signal | Measures lifetime |

| Route delays | Delay events

thermal EPP cooler box premium |

Stress test | Shows real value |

Practical tips and suggestions

-

Start small: pilot 20–50 boxes on your worst routes.

thermal EPP cooler box premium

-

Compare fairly: same route, same product, same packing SOP.

thermal EPP cooler box premium

-

Avoid false wins: measure at least 4 weeks because weather varies.

thermal EPP cooler box premium

Real case: A last-mile operator justified premium boxes after calculating that cutting two reships per week covered the monthly cost difference.

thermal EPP cooler box premium

2025 latest developments and trends for thermal EPP cooler box premium programs

In 2025, thermal EPP cooler box premium programs are moving toward reuse, standardization, and operational simplicity. Operators prefer fewer box models and train teams to pack them perfectly.

thermal EPP cooler box premium

Visual SOPs and packing diagrams are replacing long manuals, because they reduce mistakes under pressure.

thermal EPP cooler box premium

Cleanliness expectations are rising too, because reuse programs live or die by consistent cleaning and drying routines.

thermal EPP cooler box premium

Latest progress snapshot

-

More standard sizes: one “workhorse size” plus one larger option.

thermal EPP cooler box premium

-

Faster training: visual SOPs outperform long manuals.

thermal EPP cooler box premium

-

Higher hygiene bar: consistent cleaning + drying routines are now expected.

thermal EPP cooler box premium

Market insight: customers are more sensitive to “proof of control.” Even food delivery teams are building simple records and SOPs to protect trust during disruptions.

thermal EPP cooler box premium

Frequently asked questions

Q1: How long can a thermal EPP cooler box premium hold temperature?

It depends on starting temperature, coolant choice, packing method, and opening frequency. Control those, and retention improves.

thermal EPP cooler box premium

Q2: Is a thermal EPP cooler box premium better than a cheap insulated box?

Often yes for daily reuse, stacking, and rough handling. Premium boxes tend to seal more consistently and last longer.

thermal EPP cooler box premium

Q3: Can I use a thermal EPP cooler box premium for frozen items?

Yes, but frozen stability depends heavily on coolant strategy and fast closure discipline during handling.

thermal EPP cooler box premium

Q4: What is the biggest mistake with reusable thermal EPP boxes?

Storing boxes wet. Moisture increases odor issues and reduces hygiene confidence across reuse cycles.

thermal EPP cooler box premium

Q5: What should I validate first for a thermal EPP cooler box premium?

Validate peak temperature and time out of range on your worst hot lane, then lock a lane kit recipe.

thermal EPP cooler box premium

Summary and recommendations

A thermal EPP cooler box premium is worth it when your real routes include delays, repeated opening, stacking, and rough handling. The biggest gains come from seal quality, right-sizing to reduce air gaps, and consistent pack-out maps. Temperature retention improves most when you control starting temperature, lid closure, packing pattern, and open-time discipline.

thermal EPP cooler box premium

Action plan: pilot one thermal EPP cooler box premium size on your worst route for 30 days. Train one pack-out map, enforce a 10-second lid check, and track complaints and replacements weekly. Then scale the best lane kit and lock it with a simple validation report.

thermal EPP cooler box premium

About Tempk

At Tempk, we help cold chain teams run reusable packaging systems that work in daily operations. We focus on repeatable outcomes: stable temperature performance, fast pack-out routines, and reuse workflows that stay clean and trackable. If you share your temperature band, payload size, transit time, and return loop model, we can help you define a thermal EPP cooler box premium lane kit and a simple validation checklist.

Call to action: Request a “Premium EPP Lane Kit Blueprint” from us—box size, pack-out map, cleaning loop, and a 2-week validation plan.