In 2025, cold chain logistics is undergoing a major transformation with the rise of thin dry ice packs. These innovative packs offer a highly efficient way to transport temperature-sensitive products like pharmaceuticals, food, and biotechnology samples. By providing reliable cooling, longer-lasting temperature control, and reducing waste, thin dry ice packs are set to revolutionize cold chain shipping. This guide will explore their key benefits, industry applications, and the latest trends in 2025.

-

How do thin dry ice packs enhance cold chain efficiency?

-

What industries can benefit from thin dry ice packaging?

-

What are the environmental impacts of using thin dry ice packs?

-

How does a thin dry ice pack compare to traditional cooling methods?

How Do Thin Dry Ice Packs Enhance Cold Chain Efficiency?

Thin dry ice packs are designed to outperform traditional cooling solutions like gel packs and ice bricks. Their main advantage lies in their ability to maintain extremely low temperatures over extended periods. Unlike traditional ice, which melts and leaves water behind, thin dry ice sublimates directly into gas, leaving no liquid residue. This results in a mess-free and highly efficient cooling solution.

Key Advantages of Thin Dry Ice Packs:

-

Improved Temperature Control: These packs maintain low temperatures of around -78.5°C, perfect for preserving temperature-sensitive products over long shipments.

-

Space-Efficiency: Thin dry ice packs take up significantly less space than traditional ice or gel packs, allowing businesses to maximize cargo capacity.

-

Cost-Efficiency: Due to their longevity and minimal space requirements, businesses can reduce packaging and shipping costs.

Industries Benefiting from Thin Dry Ice Packs

Thin dry ice packs are used across various industries that require precise temperature control during transportation.

-

Pharmaceuticals: Essential for transporting vaccines and medications that need to stay at controlled temperatures.

-

Food and Beverages: Ideal for frozen food items like seafood, meat, and ice cream, where maintaining optimal temperature is critical.

-

Biotechnology: Ensures biological samples, tissues, and organs stay preserved during transit.

| Industry | Application | Benefit |

|---|---|---|

| Pharmaceuticals | Vaccine transportation | Ensures efficacy and safety |

| Food & Beverages | Frozen goods like seafood and ice cream | Maintains freshness |

| Biotechnology | Biological specimen transport | Ensures sample integrity |

The Environmental Impact of Thin Dry Ice Packs

Environmental sustainability is a key factor in modern cold chain logistics. Thin dry ice packs are composed of solid carbon dioxide, which sublimates without leaving waste or contributing to water contamination. Unlike traditional ice or gel packs, which often require disposal and contribute to plastic pollution, dry ice packs leave no liquid residue behind.

Additionally, carbon dioxide used for dry ice is often captured as a byproduct of industrial processes, further enhancing its eco-friendly nature. However, proper handling is critical, as dry ice can be hazardous if not used in well-ventilated areas.

How Do Thin Dry Ice Packs Compare to Traditional Cooling Methods?

When compared to traditional cooling solutions, thin dry ice packs stand out in several critical areas:

| Property | Thin Dry Ice Packs | Gel Packs | Traditional Ice |

|---|---|---|---|

| Temperature | -78.5°C | -18°C to 0°C | 0°C to 4°C |

| Duration | Several days | 6–12 hours | Melts quickly |

| Water Damage Risk | No | Yes | Yes |

| Environmental Impact | Low (sublimates) | Moderate | High (water waste) |

Thin dry ice packs offer:

-

Longer cooling duration: Up to seven times longer than traditional ice packs.

-

Better space utilization: Reduced cargo size, allowing for more efficient shipping.

-

Cost-effectiveness: Reduces the need for excessive packaging, lowering overall shipping costs.

2025 Trends in Cold Chain Logistics

The cold chain industry is evolving rapidly, driven by technological advancements and growing demand for sustainable solutions. In 2025, the use of thin dry ice packs is expected to rise due to several key trends:

-

Smarter Packaging: Integration of IoT sensors for real-time temperature monitoring, allowing businesses to track shipments more precisely.

-

Sustainability Focus: Continued innovations in dry ice production, including carbon-neutral methods, will reduce environmental impact.

-

Increased Demand for Temperature Control: With the expansion of international trade, especially in pharmaceuticals and perishable goods, the need for reliable cold chain solutions is greater than ever.

How Can You Leverage Thin Dry Ice Packs for Your Cold Chain Needs?

To maximize the benefits of thin dry ice packs in your logistics operations, consider the following tips:

-

Match Pack Size to Shipment Duration: Choose packs based on the size and duration of your shipment for optimal temperature control.

-

Combine with Insulation Materials: Use dry ice packs in conjunction with high-quality insulation to extend cooling time and maintain product integrity.

-

Stay Up to Date with Regulations: Ensure compliance with local and international guidelines for shipping hazardous materials like dry ice.

FAQ: Thin Dry Ice Pack Use Cases

Q1: How long do thin dry ice packs last?

Hydrated thin dry ice packs can last up to 7 times longer than traditional ice, making them ideal for long-distance shipments.

Q2: Can I use thin dry ice packs for shipping vaccines?

Yes, thin dry ice packs maintain temperatures well below freezing, making them perfect for temperature-sensitive pharmaceuticals like vaccines.

Q3: Are thin dry ice packs eco-friendly?

Yes, dry ice is made from carbon dioxide, which is a naturally occurring substance, and sublimates without creating waste or water pollution.

Conclusion and Actionable Tips

In conclusion, thin dry ice packs are an indispensable tool for cold chain logistics, offering significant advantages in terms of temperature control, efficiency, and sustainability. Their ability to maintain low temperatures over long durations, combined with their space-saving design, makes them the perfect choice for industries like food, pharmaceuticals, and biotechnology.

Actionable Tips:

-

Evaluate your cold chain needs: Consider the temperature requirements of your products and the duration of transit when choosing cooling solutions.

-

Incorporate smart packaging: Stay ahead by combining thin dry ice packs with IoT-enabled tracking systems to monitor temperatures in real-time.

-

Ensure staff are trained: Proper handling and understanding of regulations are key to safe and efficient use.

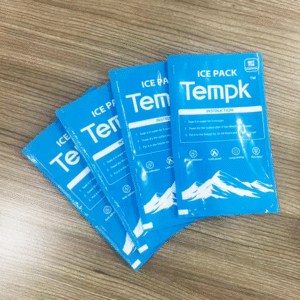

About Tempk

At Tempk, we specialize in cutting-edge cold chain solutions. Our thin dry ice packs offer reliable temperature control for sensitive shipments in industries such as pharmaceuticals, food, and biotechnology. We are committed to sustainability and efficiency, providing custom solutions for your logistics needs.

For more information or to consult with one of our experts, contact us today.