Last updated: December 8, 2025

Vegetables cold chain containers are the unsung heroes that protect crisp lettuce, juicy tomatoes and nutrient dense broccoli during their journey from farm to table. Without reliable cold chain systems, up to 13 % of the world’s food is lost and smallholder farmers can lose more than 50 % of their vegetable harvests. Properly designed containers maintain temperatures between 0–4 °C, slow microbial growth and retain vitamins. In 2025 the global cold chain market is booming, but nearly 40 % of fresh fruits and vegetables still spoil each year due to inadequate infrastructure. This guide demystifies vegetables cold chain containers, shares the latest trends, and shows you how to keep your produce fresh while meeting sustainability goals.

This article will answer:

What are vegetables cold chain containers and why do you need them? — Understand the purpose of specialised containers and why up to half of vegetable harvests are lost without them.

How do vegetables cold chain containers work? — Learn about insulation, refrigeration, phase change materials and sensors that keep produce within safe ranges.

How can you choose the right container for different vegetables? — See recommended temperature and humidity settings for leafy greens, root crops and tropical produce.

What are the latest 2025 trends and innovations? — Explore AI, IoT, blockchain and eco friendly materials transforming the vegetable cold chain.

How can you reduce waste and improve sustainability? — Discover strategies like reusable packaging, renewable energy and solar powered cold rooms that cut spoilage by up to 80 %.

What Are Vegetables Cold Chain Containers and Why Do You Need Them?

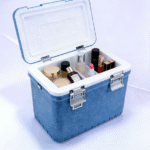

Vegetables cold chain containers are specialised shipping units designed to keep fresh produce within narrow temperature and humidity ranges from harvest to consumption. Unlike ordinary boxes, these containers incorporate insulation, refrigeration mechanisms and monitoring systems to prevent spoilage, maintain nutrients and meet regulatory requirements. Think of a vegetables cold chain container as a thermos for your veggies—it keeps them at a constant cool temperature so they don’t wilt or rot.

Post harvest losses are staggering. The United Nations estimates that 13 % of all food produced is lost because of insufficient cold chains. In sub Saharan Africa, small farmers lose more than 50 % of their vegetable harvests, and the United States still wastes 25 % of food transported in cold chains due to integrity breaches. By keeping vegetables within 0–4 °C and 90–95 % relative humidity, cold chain containers slow respiration, delay microbial growth and preserve vitamins like vitamin C. For example, broccoli stored above 5 °C quickly loses vitamin C, but containers set near freezing maintain nutrients.

Understanding the vegetable cold chain stages

Fresh vegetables travel through several stages before reaching your plate. Each stage requires a suitable container and strict temperature control to prevent losses. The table below summarises the key stages of a vegetable cold chain, the purpose of maintaining precise temperatures and why it matters to you as a grower, distributor or consumer:

| Stage of the cold chain | Purpose & recommended temperature | What this means for you |

| Production & harvest | Rapidly cool freshly harvested vegetables using forced air or hydro cooling; keep between 0–5 °C depending on variety | Quickly removing field heat slows respiration and microbial growth, preserving nutrients and extending shelf life. |

| Processing & packaging | Wash, cut and package produce under controlled temperatures and hygiene | Prevents contamination and reduces pathogen load; maintain quality during processing. |

| Cold storage | Store refrigerated vegetables at 0–4 °C and frozen stock at −18 °C | Provides buffer inventory and reduces wastage by ensuring consistent supply; prevents textural changes. |

| Transportation | Use refrigerated trucks, reefers and intermodal solutions to maintain a continuous cold chain | Ensures produce stays within target temperatures during transit; prevents spoilage across long distances. |

| Distribution & retail | Multizone distribution centres and stores keep varied temperature zones for different produce | Keeps vegetables fresh until purchased by customers; reduces shrinkage at retail outlets. |

| Consumer handling | Advise consumers to refrigerate at ≤4 °C and freeze at −18 °C; encourage prompt consumption | Sustains quality at home and reduces household waste. |

Practical tips and real world insights

Cool immediately after harvest: Use blast chillers or forced air cooling to remove field heat. Delayed cooling lets ice crystals form and damages cells, increasing spoilage.

Use proper packaging: Insulated foam containers, vacuum sealed bags and gel packs maintain temperature stability and protect against mechanical damage.

Monitor humidity: Balanced humidity (85–95 %) prevents wilting and weight loss. Breathable films allow gas exchange while retaining moisture.

Install sensors: IoT devices provide continuous temperature and humidity data, alerting operators to deviations.

Train your team: Teach staff proper loading, temperature requirements and emergency protocols to reduce human error.

Real world case: A dairy cooperative fitted IoT sensors on refrigerated trucks. When a truck door was left open, the sensor detected a temperature spike and notified staff. They closed the door quickly, saving 500 litres of milk and preventing significant losses. This example shows how sensors and prompt action keep perishable goods safe.

How Do Vegetables Cold Chain Containers Work?

Maintaining the right environment inside a vegetables cold chain container requires a combination of insulation, refrigeration and intelligent control systems. Here’s how each component contributes to keeping produce fresh.

Insulation, refrigeration and phase change materials

Insulation systems: Container walls often incorporate materials such as expanded polystyrene (EPS), polyurethane (PUR), extruded polystyrene (XPS), vacuum insulated panels (VIPs) and natural fibres. Insulation reduces heat transfer and helps maintain set temperatures. For example, VIPs use a microporous core under vacuum to achieve extremely high insulation, enabling shipments down to –80 °C. Natural fibres like wool offer recyclable alternatives but may require gel packs or phase change materials (PCMs) for longer journeys.

Active cooling units: Many containers use electric or diesel powered refrigeration units with compressors, condensers and evaporators. Portable cryogenic freezers maintain temperatures as low as –150 °C for gene and cell therapies. For vegetables, typical units keep temperatures around 0–4 °C.

Phase change materials (PCMs): PCMs absorb or release thermal energy at specific temperatures, maintaining narrow bands without constant power. A PCM market valued at US$3.6 billion in 2024 is growing at 8.4 % CAGR. For example, PCMs tuned to 0–4 °C keep leafy greens cool during transit, reducing reliance on mechanical refrigeration.

Sensors, IoT and controlled atmospheres

IoT sensors and real time monitoring: Smart sensors monitor temperature, humidity and location and send data to cloud platforms. Real time alerts allow operators to intervene when temperatures deviate, while predictive analytics forecast equipment failures. The smart container market—which includes sensors, GPS and monitoring systems—is projected to grow from US$6.07 billion in 2025 to US$30.48 billion by 2034.

Controlled atmosphere systems: For high value produce, containers can adjust oxygen and carbon dioxide levels to slow ripening. Carrier’s EverFRESH® system maintains optimal gas composition, extending shelf life for produce like berries and leafy greens.

Active packaging and intelligent packaging: Sensor based intelligent packaging integrates sensors capable of monitoring temperature, humidity and gas concentration during transport. These systems offer real time feedback on storage conditions and enhance traceability through QR codes, RFID or NFC tags. Active packaging interacts with the contents to regulate the internal atmosphere, using natural antioxidants or antimicrobial materials to slow spoilage.

Materials and technologies used in vegetable cold chain containers

Choosing the right materials influences insulation performance, cost and sustainability. The following table summarises common materials and their temperature ranges along with practical implications:

| Material or system | Typical temperature range | Characteristics & uses | Practical implications |

| Expanded Polystyrene (EPS) | 0 °C to 25 °C | Lightweight foam with moderate insulation; widely used for food and some pharmaceuticals | Affordable and easy to handle; recycling programs vary, so check local options. |

| Polyurethane (PUR) & Extruded Polystyrene (XPS) | –20 °C to 15 °C | Denser foam with higher insulation value; suitable for longer shipments | Provides extended cooling but has a higher carbon footprint; consider reusable formats to offset waste. |

| Vacuum Insulated Panels (VIPs) | –80 °C to 25 °C | Microporous core under vacuum provides extremely high insulation | Enables ultra low temperature shipping; more expensive but highly efficient. |

| Phase Change Materials (PCMs) | –50 °C to 20 °C (varies by formulation) | Absorb or release thermal energy at specific temperatures | Extend hold time and reduce payload weight; complement mechanical refrigeration. |

| Corrugated cardboard & natural fibres | 0 °C to 15 °C | Multi layer cardboard or wool inserts | Fully recyclable or compostable; may need gel packs or PCMs for longer journeys. |

| Reusable rigid containers & pallet shippers | –80 °C to 25 °C | Durable plastic or metal containers integrated with VIPs, PCMs and IoT sensors | High upfront cost but lower total cost of ownership; reusable packaging market is expected to grow from US$4.97 billion in 2025 to US$9.13 billion by 2034. |

Tips for selecting a container

Match the container to the temperature zone: Vegetable shipments fall into four general ranges—cool (10–15 °C), refrigerated (0–10 °C), frozen (–30 °C–0 °C) and ultra cold (≤–80 °C). Choose insulation and cooling technology accordingly.

Consider shipment duration: Longer transits require higher insulation (e.g., VIPs or PUR with PCMs) or active refrigeration.

Fit matters: Oversized containers waste cooling capacity and create empty space that accelerates heat transfer. Select a container that fits your load snugly.

Review regulatory requirements: Certain sectors demand precise temperature logs and tamper evident seals. Choose containers with integrated sensors and digital records to comply with laws like FSMA Rule 204.

Plan for sustainability: Reusable containers reduce waste but require reverse logistics for cleaning and redistribution. Evaluate the environmental and economic benefits over the full product life cycle.

Innovation spotlight: In regions with limited electricity, solar powered cold chain solutions reduce food waste and improve food security. Solar units allow farmers in sub Saharan Africa to preserve perishable goods for up to 21 extra days, reducing spoilage by up to 80 %. Such renewable energy systems make vegetable cold chain containers both sustainable and reliable.

How to Choose the Right Container for Different Vegetables?

Different vegetables have unique temperature and humidity requirements. Selecting a vegetables cold chain container starts with understanding these needs and matching them with the appropriate technology.

Recommended temperatures and humidity levels

Most vegetables stay fresh when stored between 0–4 °C, but some tropical crops prefer slightly higher temperatures. High relative humidity (85–95 %) prevents wilting and weight loss. The U.S. FDA’s two hour rule advises that perishable items should not sit at room temperature for more than two hours (or one hour if ambient temperatures exceed 32 °C). Exceeding these limits doubles bacterial populations every 20 minutes, increasing the risk of foodborne illness.

The table below summarises recommended conditions for common vegetable groups and why they matter:

| Vegetable group | Recommended temperature & humidity | What this means for you |

| Leafy greens (lettuce, spinach, herbs) | 0–1 °C, 95 % relative humidity | These tender crops are very sensitive to heat; keeping them near freezing with high humidity maintains crispness and nutritional value. |

| Root vegetables (carrots, beets, potatoes) | 0–4 °C, 90–95 % RH (potatoes 7–10 °C to avoid sweetening) | Prevents sprouting and retains crunch; temperatures that are too cold can convert starches to sugars in potatoes. |

| Crucifers (broccoli, cauliflower) | 0–2 °C, 95 % RH | Rapid yellowing and vitamin C loss occur above 5 °C; keeping them near freezing preserves colour and nutrients. |

| Tomatoes & cucumbers (tropical vegetables) | 10–13 °C, 85–90 % RH | Chilling injury occurs below 10 °C; mild refrigeration preserves texture and flavour. |

| Frozen vegetables | –18 °C to –23 °C, sealed packaging | Maintains colour and texture; avoid temperature fluctuations that form ice crystals and degrade quality. |

Handling practices and packaging tips

Pre cool quickly: Cool vegetables immediately after harvest using blast chillers or vacuum cooling to remove field heat. Slow cooling encourages spoilage.

Maintain humidity: Root vegetables and leafy greens require high relative humidity (90–95 %). Use absorbent liners or moisture regulating materials in your containers.

Use breathable packaging: Perforated films allow gas exchange while retaining moisture. Vacuum sealed bags reduce oxygen and slow bacterial growth but may not suit all leafy greens.

Avoid temperature abuse: Follow the two hour rule—keep produce refrigerated or frozen and minimise exposure to room temperature.

Choose materials wisely: PCMs tuned to the appropriate range maintain stable temperatures, while VIPs provide superior insulation for long transits.

Field tip: If you’re shipping cucumbers or tomatoes, avoid storing them below 10 °C. Chilling injury can cause watery, pitted tissue. Instead, select a vegetable cold chain container with slightly higher temperature control (10–13 °C). This small adjustment preserves texture and flavour.

2025 Trends and Innovations in Vegetables Cold Chain Containers

The year 2025 marks a pivotal moment for vegetables cold chain containers. Technological advancements and growing demand for fresh, sustainable foods are transforming how produce travels from farm to fork.

AI and predictive analytics

Artificial intelligence (AI) is revolutionising logistics. By analysing traffic patterns, weather conditions and delivery windows, AI driven route optimisation reduces fuel consumption and improves reliability. In smart containers, AI analyses sensor data to predict equipment failures and schedule maintenance. Predictive analytics also support demand forecasting and inventory planning, helping companies allocate capacity and reduce waste.

IoT, blockchain and digital twins

IoT and real time monitoring: Sensors continuously measure temperature, humidity and location. Real time alerts enable immediate corrective actions and dynamic routing. IoT devices also feed data into predictive models and digital twins—virtual replicas of physical assets—that allow operators to simulate different scenarios and optimise temperature control.

Blockchain and smart contracts: Blockchain creates immutable records of every step in the journey. Combined with IoT sensors, blockchain enhances transparency, prevents tampering and ensures compliance with regulations. Smart contracts automatically verify proof of delivery, trigger payments and reduce disputes.

Digital twins: Digital twins mirror the conditions inside containers and warehouses. When paired with real time data, they help forecast maintenance needs, optimise routes and adjust environmental conditions to preserve produce.

Energy efficient cooling and sustainable technologies

New cooling technologies prioritise energy efficiency and low environmental impact. Magnetic refrigeration uses magnetic fields instead of compressors, reducing energy use and CO₂ emissions. Solar powered refrigeration enables cold storage in regions with unreliable electricity, cutting fuel consumption and supporting off grid communities. Battery electric trailer units like Carrier’s Vector® HE 17 reduce fuel use by up to 30 % while delivering exceptional cooling performance. Innovations such as Addvolt’s plug in battery systems and portable cryogenic freezers offer flexible solutions for various temperature ranges.

Market outlook and consumer trends

The global cold chain logistics sector is valued at roughly US$436 billion in 2025 and could exceed US$1.3 trillion by 2034. Grand View Research estimates that the overall cold chain market—including storage and transportation—generated US$316 billion in 2024 and will soar to US$1.61 trillion by 2033, reflecting a 20.1 % compound growth rate. Consumers are demanding fresher, minimally processed foods and more plant based alternatives; plant based proteins could represent 7.7 % of the global protein market by 2030. Regulatory frameworks such as the U.S. Food Safety Modernization Act (FSMA) Rule 204 require 24 hour traceability for high risk foods, pushing distributors to digitise records and adopt sensor based traceability systems.

Social and environmental impacts

Food waste accounts for 8–10 % of global greenhouse gas emissions, and inadequate cold chain management leads to approximately 620 million metric tonnes of food loss each year. A University of Michigan study found that fully refrigerated supply chains could reduce food waste by 41 % globally. Improving vegetable cold chains not only conserves resources but also boosts farmer incomes and creates jobs, helping feed over 1 billion people who currently face food insecurity.

Sustainability: Reducing Waste and Environmental Impact

Sustainability isn’t an optional add on—it’s a necessity in 2025. Consumers, regulators and investors demand environmentally responsible cold chain solutions. The following strategies help you reduce waste and meet your sustainability goals:

Adopt reusable packaging: Reusable rigid containers reduce reliance on single use foam boxes and lower total cost of ownership. The reusable cold chain packaging market is predicted to expand from US$4.97 billion in 2025 to US$9.13 billion in 2034.

Choose eco friendly materials: Corrugated cardboard, natural fibres and biodegradable insulation offer recyclable or compostable alternatives to EPS foam.

Use renewable energy: Solar panels, wind and hydropower can drive refrigeration units, reducing fossil fuel use. Magnetic refrigeration and battery electric systems further cut emissions.

Implement energy efficient cooling: New trailer units like the Vector® HE 17 use inverter technology to reduce fuel consumption by up to 30 %. Solar powered cold rooms extend shelf life by up to 21 days and reduce spoilage by 80 %.

Follow Extended Producer Responsibility (EPR): Policies encourage companies to design recyclable or reusable packaging and ensure proper end of life management.

Collaborate on recycling: Work with logistics partners to collect materials like EPS for recycling. Educate customers on how to return or recycle packaging to close the loop.

Case example: CJ Logistics America opened a cold storage facility near Kansas City featuring automated systems, energy efficient refrigeration and IoT monitoring. This integrated approach demonstrates how investment in technology and sustainability pays off through reduced waste and improved reliability.

Practical Tips for Using Vegetables Cold Chain Containers

Effective cold chain management goes beyond choosing the right container. The following checklist outlines best practices before, during and after shipment to ensure your vegetables arrive fresh and safe.

Before shipment

Map your product portfolio: Group vegetables by required temperature zones to streamline container selection. Multi zone shippers can combine different temperatures in one load, improving utilisation by up to 30 %.

Pre condition PCMs and gel packs: Condition PCMs at the correct temperature before loading; improper conditioning reduces hold time.

Plan for contingencies: Develop emergency protocols for equipment failures or power outages. Contingency planning prevents spoilage and ensures compliance.

Train your team: Educate staff on handling procedures, data logging and emergency responses; a well trained team is your first line of defence.

Minimise empty space: Use fillers to eliminate voids and secure payloads. Empty space accelerates heat transfer and compromises packaging integrity.

Label clearly: Mark packages with handling instructions such as “Keep Frozen” and maintain records of temperature logs for regulatory compliance.

During transit

Use IoT sensors: Install smart sensors on storage units and vehicles to track temperature and humidity.

Optimise routes with AI: Employ route optimisation software to minimise fuel consumption and reduce delays.

Control humidity: Use absorbent liners or moisture regulating materials to maintain 85–95 % relative humidity for leafy greens and root crops.

Monitor in real time: Real time tracking allows you to reroute or intervene if conditions deviate.

Stay compliant: Adhere to regulatory requirements for data logging and traceability; blockchain solutions can streamline documentation.

After delivery

Verify integrity: Check temperature logs and product condition upon arrival.

Return reusable containers: Ensure reusable containers are cleaned, inspected and returned for future use.

Review data: Analyse sensor data to identify opportunities for improvement, such as route optimisation or packaging enhancements.

Gather feedback: Ask customers about delivery quality and packaging performance; continuous improvement enhances satisfaction.

Frequently Asked Questions

Q1: What temperature should vegetables cold chain containers maintain?

Most vegetables stay fresh between 0–4 °C with high relative humidity. Leafy greens prefer near freezing temperatures at 95 % humidity, while tropical vegetables like cucumbers and tomatoes should be kept at 10–13 °C to avoid chilling injury. Always pre cool produce quickly and maintain consistent conditions throughout the journey.

Q2: What’s the difference between active and passive vegetables cold chain containers?

Active containers use powered refrigeration units and can adjust temperature continuously, making them ideal for long journeys or mixed loads. Passive containers rely on insulation and phase change materials (PCMs) to maintain temperature without power. Active systems offer tighter control but consume energy, while passive solutions are cost effective for shorter trips.

Q3: How do sensors and IoT improve vegetables cold chain containers?

IoT sensors monitor temperature, humidity and location in real time and send alerts when deviations occur. This allows you to intervene quickly, reroute shipments and prevent spoilage. Sensors also feed data into blockchain systems for traceability and into digital twins for predictive modelling.

Q4: Are reusable vegetables cold chain containers worth the investment?

Reusable containers have higher upfront costs but lower total cost of ownership because they reduce the need for single use packaging. The reusable cold chain packaging market is expected to grow from US$4.97 billion in 2025 to US$9.13 billion by 2034. They also support sustainability goals by reducing waste.

Q5: How can I reduce spoilage during last mile delivery?

Use insulated totes or bags with gel packs for short trips. Minimise door openings, optimise routes to shorten delivery times, and monitor temperature with portable data loggers. Educate drivers on handling procedures and remind customers to refrigerate produce promptly upon receipt.

Summary and Recommendations

Vegetables cold chain containers are critical tools for preserving freshness, nutrient content and food safety in 2025. They combat post harvest losses—up to half of all vegetables harvested in some regions—by maintaining precise temperature and humidity ranges. Modern containers combine insulation, active or passive cooling, PCMs and smart sensors to keep produce between 0–4 °C and 90–95 % humidity. Innovations such as AI based route optimisation, IoT monitoring, blockchain traceability and digital twins provide real time visibility and predictive control. The market for cold chain logistics is expanding rapidly, and sustainability has become a core expectation: reusable containers, eco friendly materials and renewable energy systems reduce carbon footprints and waste.

Actionable next steps

Audit your supply chain: Identify where temperature excursions occur and prioritise investments in cold chain containers and sensors.

Adopt smart technologies: Implement IoT sensors, route optimisation software and, where appropriate, blockchain for traceability.

Invest in reusable, eco friendly containers: Evaluate the total cost of ownership and environmental benefits of reusable packaging.

Train and empower your team: Ensure staff understand temperature requirements, handling procedures and emergency protocols.

Engage your customers: Provide clear storage instructions and encourage proper refrigeration at home to reduce household waste.

By following these steps and leveraging the latest innovations, you can protect your vegetables, minimise waste and satisfy consumer demand for fresh, sustainably produced food.

About Tempk

Tempk is a leading provider of cold chain packaging solutions, specialising in reusable and recyclable containers designed to protect food, pharmaceuticals and other temperature sensitive goods. Our products combine advanced insulation (EPS, PUR, VIPs) with phase change materials and IoT enabled sensors to maintain precise temperatures. We conduct ongoing research into eco friendly materials and renewable energy integration to help customers reduce carbon footprints and comply with regulations. With manufacturing facilities and an R&D centre dedicated to innovation, we deliver long lasting, reliable and sustainable containers that keep your vegetables and other products fresh throughout their journey.

Ready to improve your cold chain?

Contact Tempk today for a tailored consultation. Our team will help you choose the right vegetables cold chain containers, integrate smart monitoring and implement sustainable practices that protect your produce and your bottom line.