Rising e-commerce meal kits, strict pharma-logistics rules, and climate-conscious shoppers have pushed Cooler Box Manufacturers from a niche group of foam molders into a global engine worth nearly US $8.5 billion by 2025, growing 8.5 % annually.

1 | Who’s who in the factory row

Legacy names—Sonoco ThermoSafe, Softbox, B Medical Systems, Nilkamal, and Cold Chain Technologies—still supply most validated EPS and PUR shippers, while retail-oriented brands like Yeti and Igloo dominate hard coolers. Meanwhile, regional molders in India, Vietnam, and Mexico shorten lead times for grocery platforms that can’t wait eight weeks for a container.

2 | Innovation checkpoints

The fastest-moving Cooler Box Manufacturers are swapping fossil foams for recyclable honeycomb paper, molded pulp, or post-industrial-recycled (PIR) panels; DS Smith’s all-paper cooler is a recent headline example. Packaging Technology Today Others add sensors and active cooling—Ember’s self-refrigerated Cube keeps vaccines at 2 – 8 °C for 72 h while streaming GPS and temperature to the cloud.

3 | Choosing the right partner

-

Thermal science – Look for ISO 17025 test labs, ISTA 7D profiles, and lane-specific OQ/PQ reports.

-

Scalability – Distributed molding or rental fleets that cushion holiday peaks.

-

Circularity – Take-back programs and mono-material designs that slide into curbside recycling.

-

Data & service – 24/7 lane analytics, refurbishment, and kitting support.

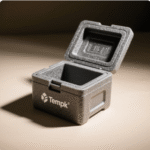

4 | Tempk™ Insulated Box: a quick spotlight

Tempk’s reusable EPP/VIP hybrid insulated box couples <0.025 W/m·K conductivity with click-in PCM bricks, delivering frozen, chilled, or ambient lanes without tape or liners. The rugged shell survives 100+ round-trips, shaving CO₂ and total cost per use, while its smooth, food-grade surface wipes clean in seconds—ideal for pharma returns or same-day meal kits. Backed by a 1 400 m² CNAS-calibrated R&D center, Tempk can cut custom tooling in under four weeks, giving shippers a rapid path from concept to validated shipper.