Why Temperature Control Matters

When shipping vaccines, seafood, or fresh meals:

• One degree too warm = spoiled goods

• Temperature swings = failed deliveries

• Ice melts too fast in summer heat

That’s where freezer blocks (ice bricks) save the day – they’re the steady cold keepers for sensitive cargo.

How Freezer Blocks Work

Think of them as thermal batteries:

-

Freeze solid (-18°C or custom temps)

-

Absorb heat during transit (slower than ice)

-

Hold temperature 2-5x longer than gel packs

No messy leaks – just reliable cooling in:

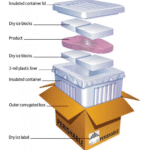

• Insulated boxes

• Medical shippers

• Food delivery bags

Where They Shine

| Industry | Problem Solved |

|---|---|

| Pharma | Keeps vaccines stable without power |

| Seafood | Prevents thawing in transit |

| Meal Kits | Stays cold through multi-stop routes |

| Hospitals | Safeguards blood samples & meds |

Tempk Ice Bricks: Why Pros Choose Them

✓ Outlast competitors

Advanced PCM core lasts 12-48+ hours (tested at 30°C)

✓ Survive rough handling

Food-grade HDPE shells won’t crack or leak

✓ Cut costs 70%

Reuse 100+ times vs. disposable gel packs

✓ Fit any operation

6 sizes from lunchbox to pallet scale

✓ Eco-approved

Recyclable & reduce packaging waste

Real-World Perks

• Pharma: Passes FDA/EU compliance audits

• Food: Keep ice cream solid in summer traffic

• E-commerce: 98% fewer spoiled grocery returns

• Clinics: Transport insulin safely