Dry Ice in Packaging: How to Keep Shipments Ultra‑Cold

You need dry ice in packaging when frozen pizza or gene therapy doses must arrive solid—no puddles, no bacteria. This guide shows you the 2025‑ready way to build a –109 °F shipping ecosystem within minutes.

-

Why choose dry ice over gel or PCM packs?

-

How much dry ice does your packaging really need?

-

Which liners, vents, and warning labels win carrier approval?

-

What new green regulations affect dry ice packaging in 2025?

Why Is Dry Ice Packaging Still the Gold Standard?

Dry ice keeps products below –60 °C for days, eliminating freeze‑thaw damage that ruins texture and potency. Water‑based gels plateau at 0 °C, but solid CO₂ sublimates—turns to gas—maintaining a far colder core.

Zooming out: think of dry ice packaging as a self‑venting cryo‑vault. As the ice sublimates, CO₂ gas pushes warm air out of the carton, further reducing heat gain. This makes it perfect for insulin, high‑fat pastries, or live research samples that must avoid condensation.

Sizing Your Dry Ice Load Correctly

| Product Weight | Dry Ice Needed | Target Duration | Benefit to You |

|---|---|---|---|

| 2 lb premium gelato | 1 lb dry ice | 24 h | Holds scoopable texture in summer |

| 10 lb frozen entrée kit | 4 lb dry ice | 48 h | Survives weekend ground transit |

| 30 lb clinical trial batch | 12 lb dry ice | 72 h | Maintains chain‑of‑custody temp |

Building a Compliant Dry Ice Package

Core steps—follow them every time:

-

Choose an EPS or VIP liner — ≥1.5 in (38 mm) thick to slow heat gain.

-

Bag the dry ice in mesh or vented film — prevents direct frostbite to products.

-

Add a gas‑escape channel — leave top flaps un‑taped by 0.25 in.

-

Apply “UN1845 Dry Ice” label plus net weight — meets IATA & DOT rules.

Field proof: A Midwest seafood co‑op reduced carrier fines by 90 % after adopting step‑3 vent channels, avoiding lid‑burst incidents during flight climbs.

Safety Checklist Before Sealing

-

Gloves & goggles: –78 °C burns skin in <5 sec.

-

No airtight coolers: Pressure can exceed 50 kPa.

-

Transport in ventilated vans: CO₂ displaces oxygen.

2025 Trends Shaping Dry Ice Packaging

-

Recycled‑CO₂ dry ice pellets now account for 40 % of U.S. supply, slashing cradle‑to‑gate emissions.

-

Smart liner inserts packed with NFC chips ping temp and CO₂ levels to a shipper dashboard.

-

Carrier scorecards focus on sustainable insulation—paper honeycomb liners replacing petroleum foam.

Market Insight

The global frozen meal‑kit sector grew 14 % in 2024, propelling demand for modular dry ice packaging that fits through apartment lockers.

Frequently Asked Questions {#faq}

How long does 5 lb of dry ice last in packaging?

Typically 40–48 hours in a 2‑inch VIP‑lined shipper at 70 °F ambient.

Can I layer dry ice above the products?

Yes. Sandwiching ice top and bottom evens out cold zones, but always use vented pouches, not loose slabs.

Is dry ice packaging allowed for ground courier?

Absolutely, if the box is vented, labeled “UN1845,” and under carrier weight limits (usually 200 lb).

Key Takeaways

-

Dry ice outperforms gels by staying –78 °C, not 0 °C.

-

Use roughly 0.4 lb dry ice per pound of frozen goods for 48‑hour lanes.

-

Venting, labeling, and eco‑friendly liners keep you compliant and green.

Action Plan

-

Audit your lane temps and choose the table’s dry ice weight.

-

Switch to recycled‑CO₂ pellets and NFC liners.

-

Need a design review? Book a free Tempk packaging consult now.

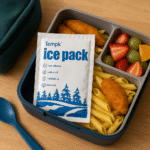

About Tempk

At Tempk, we engineer smart cold‑chain solutions—from recycled dry ice pellets to cloud‑tracked shippers—so your perishables win the last‑mile freshness race.

Ship colder. Ship cleaner. Contact Tempk today.