Insulin and many biological medicines must be kept cool but never frozen. They typically require storage between 2 °C and 8 °C, and both heat and freezing will damage themfda.gov. Dry ice, on the other hand, sits around –78 °C, which can freeze medications if used incorrectly. This guide answers whether dry ice packs are suitable for transporting insulin or other temperature‑sensitive medicines, explains safer alternatives like gel packs and phase‑change materials (PCMs), and highlights how 2025 cold chain innovations are transforming pharmaceutical logisticstempcontrolpack.com. By the end, you’ll know how to keep your medicines safe during travel or shipping while complying with current regulations.

-

Understand why insulin and similar medicines need refrigeration and must not be frozen

-

Assess whether dry ice packs are appropriate for your medicine’s temperature range

-

Discover safer alternatives such as gel packs and phase‑change materials

-

Learn about 2025 innovations like IoT sensors, sustainable packaging and smart logistics in the cold chain

-

Find answers to common questions about traveling with insulin and dry ice

Why Temperature Matters: Insulin and Medicine Storage Explained

The Science Behind Insulin Storage

Insulin is highly sensitive to temperature fluctuations and quickly loses potency if exposed to extremesfda.gov. Regulatory guidelines from the U.S. Food and Drug Administration (FDA) advise storing insulin between 36 °F and 46 °F (2 °C–8 °C) and keeping it away from direct heat or sunlightfda.gov. When left at room temperature (59 °F–86 °F), most insulin formulations remain stable for about 28 days, but they must never be frozenfda.gov. Harvard Health notes that if insulin has been frozen—even once—it should not be used because freezing degrades the protein molecules and diminishes its therapeutic effecthealth.harvard.edu. Similar caution applies to other biologics, where freezing can cause irreversible aggregation or precipitation.

At the other end of the spectrum, heat can destroy insulin just as quickly. The Centers for Disease Control and Prevention (CDC) warns that high temperatures accelerate insulin breakdown and can render it ineffectivecdc.gov. That’s why travellers are advised to keep insulin in insulated pouches and avoid leaving it in hot cars or in direct sunlight. For people who rely on insulin every day, maintaining a steady refrigerated environment is critical; even minor temperature spikes or dips can lead to hyperglycemia or hypoglycemia episodes due to inconsistent dosing.

Not All Medicines Share the Same Temperature Range

While insulin needs refrigeration, not all pharmaceuticals fall into the 2 °C–8 °C range. Some vaccines—such as mRNA COVID‑19 vaccines—must be kept between –90 °C and –60 °C, whereas other biologics like monoclonal antibodies require –25 °C to –15 °Ctempcontrolpack.com. Antibiotics reconstituted for injection often share insulin’s 2 °C–8 °C requirement. This variation underscores why knowing your medicine’s exact storage range is essential before choosing a cooling method.

Comparing Storage Requirements for Different Medicines

| Medicine Type | Safe Temperature Range | Dry Ice Compatible? | Practical Meaning |

|---|---|---|---|

| Insulin | 2 °C–8 °C | ❌ No | Use gel packs or PCMs; avoid freezingtempcontrolpack.com |

| mRNA Vaccine | –90 °C to –60 °C | ✅ Yes | Dry ice or ultra‑cold freezers requiredtempcontrolpack.com |

| Monoclonal Antibody | –25 °C to –15 °C | ✅ With buffer | Requires dry ice but must be separated by a spacer to avoid crackingtempcontrolpack.com |

| Reconstituted Antibiotic | 2 °C–8 °C | ❌ No | Use gel packs or refrigerated carrierstempcontrolpack.com |

The table above shows that insulin and many common injectable medicines are not compatible with dry ice because their safe range is above freezing. Direct contact with dry ice can freeze and ruin these productstempcontrolpack.com. Only medicines explicitly labeled “keep frozen” (e.g., certain vaccines) should be packed with dry ice.

Tips for Keeping Insulin Safe During Travel

-

Use gel packs or phase‑change packs designed for 2 °C–8 °C. These maintain a cool environment without freezing the medicine.

-

Place insulin in an insulated pouch and keep the pouch inside a cooler for extended trips. Avoid direct contact between the medicine and ice packs.

-

Monitor the temperature using a portable data logger or thermometer. Many travel cases include built‑in sensors.

-

Never store insulin in checked luggage when flying; temperature in cargo holds can be extreme. Carry it in your hand luggage with an explanatory doctor’s note.

-

Inspect insulin vials for cloudiness or clumps after travel. If you suspect freezing or overheating, consult a healthcare professional before use.

Real Case: During Hurricane Katrina, many diabetics lost access to refrigeration. Emergency guidelines from the American Diabetes Association recommend using reusable gel packs and caution that dry ice should not be used because it will freeze medicationdiabetes.org. People who followed these guidelines maintained their insulin’s efficacy until they regained access to regular supplies.

Are Dry Ice Packs Suitable for Insulin?

Understanding Dry Ice

Dry ice is the solid form of carbon dioxide (CO₂) and maintains a temperature around –78.5 °C (–109.3 °F) as it sublimates. It offers powerful cooling and is widely used for shipping frozen foods and ultra‑cold vaccines. However, its extreme cold makes it unsuitable for medicines that must not freeze. According to shipping guidelines, dry ice should only be used when the product’s safe temperature range is below –20 °C and there is no risk of damageipcpack.com. Even then, the product should never touch the dry ice directlyups.com.

Why Dry Ice Can Damage Temperature‑Sensitive Medicines

Direct contact with dry ice can freeze medicines that require only refrigeration. The cooling element at –78 °C can cause crystallization and structural damage in proteins like insulin. A 2025 guide from cold chain manufacturer Tempk notes that if a medicine only needs 2–8 °C, direct contact with a –78 °C dry‑ice pack can freeze and ruin ittempcontrolpack.com. The guide advises placing a buffer layer—such as phase‑change gel packs or a 1‑inch foam spacer—between the medication and dry ice to prevent freeze shocktempcontrolpack.com.

Furthermore, major health organizations advise against using dry ice for insulin. The American Diabetes Association’s emergency preparedness plan states: “Do NOT use dry ice and do not freeze the medication” when storing insulin during power outagesdiabetes.org. The American Association of Clinical Endocrinology similarly recommends a cooler with re‑freezable gel packs and warns not to use dry iceaace.com. The reason is clear: once insulin freezes, the protein structure denatures and the vial must be discarded.health.harvard.edu

When Dry Ice Is Appropriate

While dry ice is not appropriate for insulin, it is essential for medicines that require subzero or ultra‑cold temperatures. mRNA vaccines must be kept between –90 °C and –60 °C, and certain monoclonal antibodies require –25 °C to –15 °Ctempcontrolpack.com. For these products, dry ice provides the necessary ultra‑cold environment. However, even in these cases, packaging must include a buffer layer to prevent glass vials from crackingtempcontrolpack.com and to allow CO₂ gas to vent safely.tempcontrolpack.com

Safe Packing Steps for Dry Ice

If you are shipping products that are compatible with dry ice, follow these 2025 safety steps:

-

Wear cryogenic gloves to prevent skin burns when handling dry icetempcontrolpack.com.

-

Line the bottom of the cooler with a corrugated board to absorb condensation and protect packagestempcontrolpack.com.

-

Add a layer of dry ice packs, then place a buffer sheet (foam or cardboard) over the dry icetempcontrolpack.com.

-

Place the medicine in a sealed pouch with a temperature probe so you can monitor conditionstempcontrolpack.com.

-

Add additional dry ice packs, leaving a small headspace for expansiontempcontrolpack.com.

-

Vent the container; CO₂ gas must escape to avoid pressure builduptempcontrolpack.com.

-

Label the shipment “Dry Ice (≤2.5 kg), UN1845, Class 9” to comply with airline and shipping regulationstempcontrolpack.com.

Interactive Tip: Need to calculate how much dry ice your shipment requires? Use our Pack‑Size Calculator to determine the exact weight based on your cooler size and journey time.

Alternatives to Dry Ice: Gel Packs and Phase‑Change Materials

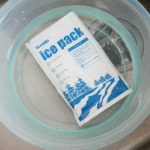

Why Gel Packs Are Safer for Insulin

Gel packs, often called cold packs or ice packs, contain a phase‑change material that melts around 0 °C to 4 °C. This moderate temperature keeps medicines cool without freezing. An article comparing cold packs with dry ice notes that cold packs are best for maintaining the temperature of chilled goods above 32 °F (0 °C) and are more appropriate for injectable medicines like insulin, which need 2 °C–8 °Cipcpack.com. Dry ice, by contrast, is best for items that need to remain frozen and should never be packed with products sensitive to freezingipcpack.com.

Another reference from tempcontrolpack emphasizes that ice packs are perfect for maintaining 2–8 °C for medical items and notes that phase‑change gel packs ensure temperatures stay within the safe range for insulintempcontrolpack.com. Because gel packs do not reach subzero temperatures, there is no risk of freezing the medication.

Introduction to Phase‑Change Materials (PCMs)

Phase‑change materials absorb and release large amounts of latent heat during melting and solidification. By engineering PCMs to melt at specific temperatures—such as 5 °C—manufacturers create cooling packs that maintain a consistent temperature within a narrow range. PCMs offer several advantages:

-

Precision: They maintain a stable temperature for hours or days, reducing the risk of temperature excursions.

-

Reusability: Many PCM packs can be recharged hundreds of times, cutting down on waste.

-

Sustainability: PCMs are increasingly developed using eco‑friendly materials, making them a greener alternative to single‑use gel packsarchivemarketresearch.com.

-

Regulatory compliance: Integrated data loggers and smart packaging options simplify regulatory reporting.

A 2025 market report highlights that the global cold chain logistics PCM market is estimated at US $500 million and expected to grow at 8 % CAGR from 2025 to 2033, driven by demand from pharmaceuticals and vaccinesarchivemarketresearch.com. The report notes that organic PCMs currently hold a larger share than inorganic PCMs because of their better environmental profile and suitability for medical applicationsarchivemarketresearch.com. Innovations such as nano‑encapsulation and integrated PCM packaging are being developed to improve thermal properties and ease of usearchivemarketresearch.com.

Choosing the Right Cooling Method: Gel Packs vs Dry Ice vs PCMs

| Cooling Method | Temperature Range Maintained | Best Use Cases | Pros | Cons |

|---|---|---|---|---|

| Gel Packs | ~0 °C–8 °C | Insulin, antibiotics, vaccines requiring refrigeration | Safe for medicines that must not freeze; inexpensive; widely available | Limited duration; may require multiple packs for long trips |

| Phase‑Change Materials (PCMs) | Customizable (e.g., 2 °C–8 °C, –20 °C) | High‑value biologics requiring precise control | Stable temperature for extended periods; reusable; eco‑friendly options; can integrate sensors | Higher upfront cost; heavier than gel packs |

| Dry Ice | –78 °C | Medicines labeled “keep frozen” (e.g., some vaccines, cell therapies) | Maintains ultra‑cold temperatures; essential for frozen shipments | Will freeze insulin and similar medicines; requires buffer layers; regulated for air travel |

Using Gel Packs Correctly

To maximize gel pack performance for insulin:

-

Pre‑freeze gel packs for at least 24 h before use.

-

Wrap gel packs in a cloth to prevent condensation from touching medicine containers.

-

Use an insulated container to slow down warming; fill empty spaces with crumpled paper or foam.

-

Add a PCM brick on top of the gel packs if you need to maintain 2 °C–8 °C for more than 24 h.

-

Monitor temperature with a data logger and replace gel packs if they warm above 8 °C.

Internal Link Suggestions

-

Learn more about choosing the best gel packs for insulin travel (anchor text: “insulin travel cases with gel packs”).

-

Read our guide on phase‑change materials for medical shipments (anchor text: “PCM cold chain solutions”).

-

Explore dry ice safety for vaccines (anchor text: “dry ice shipping regulations”).

-

Discover insulated medical cooler bags that integrate temperature sensors (anchor text: “insulated cooler bags for medicines”).

-

See how smart data loggers improve compliance (anchor text: “IoT temperature monitoring devices”).

2025 Innovations Transforming the Cold Chain

Sensor Technologies and Digital Monitoring

Cold chain logistics is rapidly shifting from reactive containment to proactive, data‑driven control. Press releases on temperature‑controlled packaging emphasize that industry innovation is being driven by sensor technologies and data analyticsbusinesswire.com. Real‑time monitoring allows stakeholders to see the exact temperature, humidity, and location of shipments and to take immediate corrective action if a deviation occursbusinesswire.com.

In Southeast Asia, IoT‑enabled smart sensors are already transforming pharmaceutical logistics. These devices attach to packaging and transmit temperature and GPS data in real time. If a sensor detects that the temperature is moving out of range, it can alert logistics teams through text or app notifications, enabling them to intervene before the medicine is damagedpharmanow.live. These sensors also support predictive maintenance of refrigeration units and improve route planning by providing live traffic updates.pharmanow.live

Sustainable Packaging and Eco‑Friendly Materials

Sustainability is becoming a central pillar of cold chain design. Pressure to reduce plastic waste and carbon emissions is prompting companies to adopt recyclable insulated containers, biodegradable thermal wraps, and reusable cold packspharmanow.live. The same article notes that sustainable packaging not only protects temperature‑sensitive products but also reduces the environmental footprint of pharmaceutical distributionpharmanow.live. Market research highlights a move toward eco‑friendly phase‑change materials, noting that organic PCMs hold a larger market share due to their lower environmental impactarchivemarketresearch.com.

Blockchain for End‑to‑End Traceability

Blockchain technology is emerging as a powerful tool for secure, tamper‑proof tracking in the cold chain. By creating a distributed ledger of transactions, blockchain ensures that every shipment step—from manufacturing to delivery—is recorded and verifiable. This transparency safeguards sensitive medical data and intellectual property, and fosters trust among stakeholderspharmanow.live. In the context of vaccine distribution, blockchain can log temperature readings at each checkpoint and provide regulators with instant proof of compliance.

Solar‑Powered Cold Storage and AI‑Powered Route Optimization

Innovators in Southeast Asia are deploying solar‑powered cold storage units to address unreliable power grids. These units reduce energy costs while providing sustainable refrigeration for rural clinicspharmanow.live. Similarly, artificial intelligence (AI) is being used to optimize delivery routes for temperature‑sensitive medicines. AI algorithms analyze real‑time traffic and weather data to plan the fastest, safest route, reducing transit times and preventing product spoilagepharmanow.live. Combined with IoT sensors, AI can predict temperature excursions before they happen and trigger corrective actions.

Portable Cryogenic Freezers and Ultra‑Cold Logistics

Portable cryogenic freezers are a new solution for biologics and cell therapies requiring –80 °C to –150 °C. These mobile units maintain ultra‑cold temperatures even in remote or infrastructure‑poor environmentspharmanow.live. Real‑time temperature tracking systems and warning alerts protect these high‑value therapies during transitpharmanow.live. While such devices are not necessary for insulin, they underscore the diversity of temperature requirements across pharmaceutical products.

Cold Chain Market Growth and Tariff Impacts

The temperature‑controlled packaging market is poised for rapid expansion. A 2025 industry report notes that the realm of temperature‑controlled packaging plays a crucial role in maintaining the integrity of biologics, vaccines and sterile injectables, and innovations are shifting the industry toward proactive, intelligent and data‑driven modelsbusinesswire.com. Segmentation by packaging type distinguishes between active systems (electric coolers and PCM‑equipped units) and passive systems (foam insulation, gel packs, dry ice), with each tailored to product thermal sensitivitybusinesswire.com.

The report also points out that new U.S. tariffs in 2025 have increased costs for temperature‑controlled packaging components, pushing companies to explore near‑shoring and diversified supply strategiesbusinesswire.com. Despite these challenges, investment in IoT integration and sustainable materials continues to acceleratebusinesswire.com.

Five Innovations to Watch

-

Blockchain traceability: Transparent tracking for vaccines and biologicspharmanow.live.

-

Solar‑powered cold storage: Off‑grid refrigeration for remote clinicspharmanow.live.

-

IoT smart sensors: Real‑time monitoring and predictive alertspharmanow.live.

-

AI‑powered route optimization: Faster delivery with reduced spoilagepharmanow.live.

-

Portable cryogenic freezers: Ultra‑cold transport for cell therapiespharmanow.live.

These innovations reflect a broader trend toward sustainable, connected and intelligent cold chains, giving healthcare providers and patients greater confidence that medicines arrive potent and safe.

Frequently Asked Questions

Q1: Can I use dry ice to keep my insulin cool during a long flight?

No. Dry ice is around –78 °C and will freeze insulin. Health organizations specifically advise against using dry ice for insulin and recommend gel packs or PCM-based travel cases insteaddiabetes.orgtempcontrolpack.com. Use an insulated case with gel packs and keep insulin in your carry‑on bag.

Q2: How long do gel ice packs keep insulin cold?

High‑quality gel packs pre‑frozen for 24 h can maintain a 2 °C–8 °C environment for 12–24 h, depending on ambient temperature and container insulation. For longer trips, add a PCM brick or swap out gel packs every 24 h.

Q3: Do airlines allow dry ice for medical shipments?

Yes, but with strict limits. Most airlines cap dry ice at 5.5 lb (2.5 kg) per passenger and require a vented container labeled “Dry Ice (≤2.5 kg), UN1845, Class 9.” Always inform the airline in advancetempcontrolpack.com. However, unless your medicine requires subzero temperatures, gel packs are easier and less regulated.

Q4: Are phase‑change materials safe and reusable?

Absolutely. PCMs are engineered to melt and solidify at specific temperatures, maintaining a stable environment for many hours. Many PCM packs are reusable for over 100 cycles and are available in eco‑friendly formulationsarchivemarketresearch.com. Choose a PCM with a melting point appropriate for your medicine (e.g., 5 °C for insulin).

Q5: How can I monitor my medicine’s temperature during travel?

Use a digital data logger or smart sensor that logs temperature and alerts you when values approach the upper or lower limit. Some travel cases include Bluetooth sensors that transmit data to your smartphone, giving you real‑time visibility and peace of mindtempcontrolpack.com.

Summary & Recommendations

Proper temperature control is critical for insulin and other biologics. Insulin should never be frozen and must be stored between 2 °C and 8 °Cfda.gov. Because dry ice is around –78 °C, it is unsuitable for insulin and medicines with similar temperature requirementstempcontrolpack.com. Instead, use gel packs or phase‑change materials that maintain a safe range without risking freeze damageipcpack.comtempcontrolpack.com. For medicines labeled “keep frozen,” dry ice is appropriate but must be separated by buffer layers and used under strict safety protocolstempcontrolpack.com.

Emerging innovations in 2025—such as IoT sensors, blockchain traceability, AI route optimization and sustainable packaging—are making cold chains smarter and more reliablepharmanow.live. The global market for phase‑change materials is growing and offers eco‑friendly, precise temperature controlarchivemarketresearch.com. Whether you’re a patient, pharmacist or logistics professional, staying informed about these developments will help you make better decisions and ensure that every dose of medicine arrives potent and safe.

Action Plan

-

Identify your medicine’s temperature requirements (check labels or consult your pharmacist).

-

Choose an appropriate cooling method: gel packs or PCMs for refrigerated medicines; dry ice only for items requiring subzero storage.

-

Pack properly: pre‑freeze gel packs, use insulated containers, and avoid direct contact between medicine and ice.

-

Monitor temperatures with a data logger or smart sensor; respond to alarms promptly.

-

Stay informed about new cold chain technologies. Subscribe to our newsletter for updates on IoT devices, sustainable packaging and regulatory changes.

-

Contact our cold chain specialists for personalized guidance on packaging and compliance.

About Tempk

Tempk is a leader in cold chain packaging solutions, offering insulated shippers, phase‑change material bricks and smart data loggers that safeguard pharmaceuticals for up to 120 hours. Our products are CNAS‑accredited and undergo rigorous stress tests to ensure reliability in clinics, clinical trials and last‑mile deliveriestempcontrolpack.com. We prioritize sustainability by developing reusable and recyclable packaging and by integrating real‑time temperature monitoring into our solutions. Whether you’re shipping insulin across town or biologics across continents, we tailor our systems to your needs.

Ready to protect your medicines? Contact Tempk’s cold chain experts today for a free consultation.