When shipping perishable goods, maintaining a stable temperature is critical to ensuring product integrity. Dry ice packs, made from solid carbon dioxide (CO₂), offer a powerful solution to keep items frozen during transit. As the cold chain logistics industry evolves in 2025, understanding the latest regulations, best practices, and innovative trends in using dry ice for shipping is crucial for compliance and safety.

What Are Dry Ice Packs for Shipping?

Dry ice packs are sheets, blocks, or pellets of solid CO₂, designed to keep temperature-sensitive products at ultra-low temperatures. Unlike conventional ice, dry ice sublimates directly into gas without leaving behind any liquid residue. This feature makes it ideal for shipping items that require freezing, such as pharmaceuticals, biological samples, and certain perishable foods.

Why Use Dry Ice for Shipping?

Dry ice packs are an excellent choice for shipping due to their unique properties, providing several advantages over traditional cooling methods.

-

Long-Lasting Cooling Power: Dry ice sublimates at a much slower rate than regular ice, ensuring your goods remain cold for longer durations.

-

No Moisture Runoff: Since dry ice does not melt into water, there’s no risk of water damage to sensitive items.

-

Ideal for Extended Transit: For shipments lasting more than 48 hours, dry ice is often the preferred choice for keeping goods frozen.

2025 Regulations for Shipping Dry Ice

Shipping dry ice is subject to strict regulations due to its classification as a hazardous material. In 2025, the following key regulations must be adhered to when shipping dry ice:

-

UN Number: Packages containing dry ice must be clearly labeled with the UN number “1845.”

-

Class 9 Hazard Label: A Class 9 hazardous materials label must be affixed to the package.

-

Weight Declaration: The net weight of dry ice in kilograms must be marked on the package.

-

Venting Requirements: Packaging must allow CO₂ gas to escape to avoid pressure buildup during sublimation.

For air transport, the International Air Transport Association (IATA) limits the amount of dry ice per package to 2.5 kg on passenger aircraft and up to 200 kg on cargo flights.

Best Practices for Using Dry Ice Packs in Shipping

To ensure the safe and efficient use of dry ice for shipping, follow these best practices:

1. Select Appropriate Packaging

-

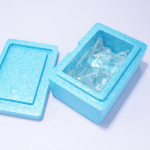

Insulated Containers: Use insulated coolers or Styrofoam containers to maintain the desired temperature.

-

Vented Packaging: Ensure the container has ventilation holes to allow CO₂ gas to escape during sublimation.

-

Cushioning: Properly secure items inside the packaging to prevent damage during transit.

2. Calculate the Amount of Dry Ice

Determine the quantity of dry ice based on the transit duration and the perishability of the goods. A common guideline is to use 2.5 kg of dry ice for every 24 hours of shipping.

3. Label Packages Correctly

-

Mark the package clearly with “Dry Ice” or “Carbon Dioxide, Solid.”

-

Attach the UN Number (1845) and Class 9 Hazard Label.

-

Specify the net weight of dry ice in kilograms.

Common Mistakes to Avoid

-

Sealed Containers: Never use airtight containers to pack dry ice; this can cause dangerous pressure buildup.

-

Incorrect Labeling: Ensure all required labels are attached to avoid delays or rejections by shipping carriers.

-

Exceeding Weight Limits: Stick to the weight regulations to prevent violations of hazardous materials rules.

Alternatives to Dry Ice

While dry ice is effective, several alternatives may be more suitable depending on your shipment requirements:

-

Gel Packs: Reusable and non-hazardous, ideal for shorter transit times.

-

Phase Change Materials (PCMs): These materials maintain specific temperature ranges and are reusable, offering a more sustainable option.

-

Traditional Ice Packs: While cheaper, ice packs can leave water residue, potentially damaging goods.

Sustainability and Trends in Dry Ice Shipping

In 2025, several emerging trends are shaping the dry ice shipping industry, focused on both environmental sustainability and technological advancements.

1. Sustainable Dry Ice Production

Many suppliers are shifting toward environmentally friendly production methods by capturing CO₂ from industrial processes, such as ammonia synthesis, reducing the overall carbon footprint of dry ice.

2. Hybrid Packaging Solutions

Hybrid solutions combining dry ice and PCMs are gaining popularity. These packouts minimize CO₂ use while extending the cooling duration, making them more eco-friendly.

3. Smart Packaging and Tracking Technology

Innovations such as smart CO₂ sensors and QR-coded labels allow for real-time tracking of dry ice and product temperatures, ensuring better monitoring and compliance.

How to Store Dry Ice Packs for Shipping

Proper storage is essential to maximize the shelf life and effectiveness of dry ice packs:

-

Store in an Insulated Container: Use coolers or specially designed containers to slow sublimation.

-

Avoid Sealed Containers: Never store dry ice in airtight or sealed containers; always ensure proper ventilation.

-

Monitor Sublimation Rates: Keep track of the rate at which dry ice sublimates to ensure the correct temperature is maintained.

Frequently Asked Questions About Dry Ice for Shipping

Q1: How long does dry ice last during shipping?

Dry ice can last between 18 to 24 hours depending on the type of packaging and external conditions. Blocks of dry ice last longer than pellets.

Q2: Is dry ice safe to ship?

Yes, dry ice is safe for shipping when packaged according to safety guidelines, including proper ventilation and labeling.

Q3: Can dry ice be used for shipping food?

Yes, dry ice is commonly used for shipping frozen and perishable foods, as long as the necessary safety measures are followed.

Conclusion and Recommendations

Dry ice packs are a powerful tool for shipping temperature-sensitive products in 2025. By choosing the right supplier and adhering to best practices for packaging, storage, and safety, you can ensure that your products arrive at their destination in optimal condition.

Action Plan:

-

Determine the required temperature range for your shipment (frozen vs chilled).

-

Calculate the correct amount of dry ice based on shipment duration.

-

Verify regulatory compliance and ensure proper packaging and labeling.

-

Consider hybrid packaging solutions to improve sustainability and cost-efficiency.

About Tempk

Tempk is a leading provider of cold chain packaging solutions, offering high-quality dry ice and other thermal control products to ensure the safe and efficient transport of temperature-sensitive goods. We specialize in helping businesses optimize their logistics while adhering to all relevant safety and regulatory standards.

Contact Tempk today to learn more about our dry ice solutions and how we can help streamline your cold chain shipments.