Cold Chain Box: Essential Guide to Safe and Efficient Temperature-Controlled Shipping

In the world of logistics and supply chain management, cold chain boxes play a pivotal role in maintaining the quality and safety of temperature-sensitive products. Whether it’s pharmaceuticals, food, or biotechnology, a cold chain box ensures that goods remain at the required temperatures from origin to destination. In this guide, we will explore everything you need to know about cold chain boxes, their importance, benefits, and how to choose the right one for your business.

-

What is a cold chain box, and why is it critical for temperature-sensitive shipments?

-

How does a cold chain box work to ensure product safety?

-

What industries rely on cold chain boxes the most?

-

What are the key features to look for when selecting a cold chain box?

-

How to maintain and optimize your cold chain boxes for long-lasting use?

What is a Cold Chain Box, and Why is it Critical for Temperature-Sensitive Shipments?

A cold chain box is a specialized container designed to maintain a consistent temperature range for sensitive goods during transport. These boxes are essential in industries like pharmaceuticals, food, and biotechnology, where maintaining a certain temperature is critical to the product’s integrity. Cold chain boxes are constructed to keep items cold (or sometimes frozen) by utilizing insulating materials, refrigerants, and temperature-controlled systems.

Core Insight: Cold chain boxes ensure that temperature-sensitive products such as vaccines, perishable foods, and biologics maintain their quality and effectiveness throughout the entire supply chain process. This is essential for preventing spoilage or loss of efficacy.

The box typically contains features like insulation, gel packs, or dry ice to provide the necessary cooling or freezing effect. Depending on the product and shipping duration, these boxes can maintain low temperatures for hours, days, or even weeks.

How Does a Cold Chain Box Work to Ensure Product Safety?

A cold chain box works by using a combination of physical and thermal properties to regulate and maintain the internal temperature. The materials used in the construction of these boxes are crucial in providing insulation and ensuring that the box remains airtight and moisture-resistant. Temperature-monitoring systems are also often incorporated to track and log temperature fluctuations during transit.

Here’s a breakdown of the cold chain box working process:

-

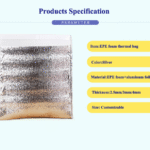

Insulating Materials: The outer walls are made of high-quality thermal insulation materials such as expanded polystyrene (EPS) or polyurethane foam.

-

Cooling Agents: Gel packs, dry ice, or liquid nitrogen are used to create the cooling effect within the box.

-

Temperature Control: A built-in temperature monitoring system allows for real-time tracking of the box’s internal conditions.

| Cold Chain Box Feature | Description | Significance |

|---|---|---|

| Insulation | High-density foam or reflective materials | Maintains a stable temperature for extended periods |

| Cooling Agents | Gel packs, dry ice, or liquid nitrogen | Ensures temperature control across varied distances |

| Temperature Control | Built-in sensors or data loggers | Tracks temperature fluctuations to prevent spoilage |

How Long Can a Cold Chain Box Keep Products Safe?

The duration for which a cold chain box can keep items within the required temperature range depends on several factors, such as the size of the box, the type of cooling agents used, and the external environment. For instance, a cold chain box designed for short-duration shipments might maintain temperatures for 48-72 hours, whereas specialized boxes used for biologics or vaccines could keep them cold for up to 10 days.

Pro Tip: When selecting a cold chain box, make sure to evaluate the shipping time and temperature requirements for your specific needs. Choosing the right duration will help optimize costs and reduce waste.

What Industries Rely on Cold Chain Boxes the Most?

Cold chain boxes are indispensable in industries where temperature control is essential for product integrity. Here’s a look at the industries that rely heavily on these temperature-controlled solutions:

-

Pharmaceuticals: For transporting sensitive medications, vaccines, and biologics that require strict temperature control.

-

Food Industry: Ensuring the safe transport of fresh produce, dairy, seafood, and frozen foods.

-

Biotechnology: For clinical samples, lab specimens, and research materials that must remain within a specific temperature range.

-

Chemicals and Cosmetics: Certain chemicals and cosmetics also require temperature-sensitive shipping to maintain their quality.

Example Application: In the pharmaceutical industry, cold chain boxes are used to ship vaccines globally, ensuring that the cold storage requirements are met from point A to point B.

What Are the Key Features to Look for When Selecting a Cold Chain Box?

When selecting a cold chain box, there are several important features to consider to ensure optimal performance and product safety:

-

Insulation Quality: Choose a box with durable and high-performing insulation materials that provide maximum thermal protection.

-

Cooling Efficiency: Evaluate the type of cooling agents used in the box and ensure they are appropriate for the temperature range needed for your products.

-

Size and Capacity: Ensure the box can accommodate the volume of products being shipped without compromising temperature control.

-

Reusability: Consider boxes that are designed for multiple uses to reduce waste and operational costs.

-

Temperature Monitoring: Look for boxes with built-in monitoring systems that offer real-time data for greater transparency and control.

Temperature Monitoring Systems: Why They Matter

An effective temperature monitoring system is crucial to ensure the safety and integrity of products being shipped in a cold chain box. These systems can provide real-time alerts about any temperature deviations, allowing businesses to take corrective actions immediately.

Case Study: A pharmaceutical company used cold chain boxes equipped with IoT sensors that provided real-time temperature data for vaccine shipments. This system helped prevent spoilage and ensured that the vaccines reached their destination within the required temperature range.

2025 Cold Chain Trends and Innovations

In 2025, cold chain logistics are rapidly evolving with new technologies and innovations. The increasing demand for biologics, vaccines, and perishable foods is driving the need for more efficient and sustainable cold chain solutions.

Key Trends in Cold Chain Box Technology

-

Advanced Insulation Materials: New materials that provide enhanced thermal protection while being lightweight and eco-friendly.

-

Smart Monitoring Systems: The rise of smart sensors and IoT devices for better temperature tracking and data logging.

-

Sustainability Initiatives: The move towards biodegradable and reusable cold chain boxes to reduce environmental impact.

Insight: The future of cold chain boxes lies in improved materials and technology that offer better temperature control and longer-lasting durability, benefiting industries with complex and time-sensitive shipping needs.

What Are the Market Insights?

As the cold chain logistics industry continues to grow, businesses are becoming more focused on finding cost-effective, sustainable, and reliable solutions for temperature-sensitive shipments. The demand for eco-friendly cold chain boxes is increasing, driven by both consumer preferences and environmental regulations.

Frequently Asked Questions

What is the ideal temperature for a cold chain box?

The ideal temperature for a cold chain box depends on the products being transported. For pharmaceuticals, it could range from 2°C to 8°C, while for frozen foods, temperatures of -18°C or lower are necessary.

How can I maintain a cold chain box?

Ensure that the box is properly cleaned after each use, replace any damaged components, and check the cooling agents before every shipment. Regular maintenance helps prolong the box’s lifespan.

Conclusion and Recommendations

Cold chain boxes are a critical component in the safe transport of temperature-sensitive goods. By understanding their features, applications, and innovations, businesses can optimize their logistics processes and ensure the highest quality of products for their customers.

Next Steps: Evaluate your cold chain shipping needs and choose the right cold chain box based on product type, duration, and required temperature range. Consult with logistics professionals to ensure the best solutions for your supply chain.

About Tempk

Tempk is a leader in cold chain logistics, offering a wide range of temperature-controlled solutions for the pharmaceutical, food, and biotechnology industries. Our cold chain boxes are designed to maintain optimal temperatures, ensuring the safe transport of sensitive products. We offer innovative, eco-friendly solutions for businesses worldwide.

Call to Action:

For personalized recommendations on cold chain solutions, contact Tempk today!