How Does a Chemical Resistant EPP Box Enhance Cold Chain Logistics?

Updated on December 1 2025

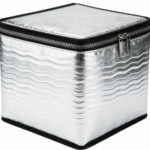

Keeping perishable goods safe is not just about temperature—it’s about durability, hygiene and sustainability. A chemical resistant EPP box is made from expanded polypropylene foam that traps air inside closed cells to block heat, absorb impacts and shrug off oils, acids and solvents. This lightweight container maintains 2–8 °C or even –18 °C for up to 72 – 96 hours, tolerates hundreds of trips and resists moisture and chemicals, making it a reliable shield for your cold chain shipments.

What is a chemical resistant EPP box and why does its closed cell foam matter?

How does chemical resistance improve safety and durability for pharmaceuticals and food?

Which industries benefit most from chemical resistant EPP boxes in 2025?

How can you select, pack and maintain an EPP box to maximize reuse?

What are the latest trends and innovations shaping chemical resistant EPP packaging in 2025?

What Is a Chemical Resistant EPP Box and How Does It Work?

A chemical resistant EPP box is a reusable insulated container made from expanded polypropylene foam that combines low thermal conductivity with strong resistance to oils, acids and solvents. Unlike brittle polystyrene, EPP forms a closed cell structure where each bead traps air, giving it exceptional insulating power and impact absorption. Its non porous surface prevents water absorption and blocks chemical spills from penetrating the foam.

Expanded polypropylene is produced by expanding tiny polypropylene beads with steam and molding them under heat and pressure. This process yields a material that is lightweight (15–100 kg m⁻³), resilient and chemically resistant. The resulting EPP box keeps vaccines within 2–8 °C or frozen seafood at –18 °C for 72 hours and, when combined with vacuum insulated panels (VIPs), can extend hold time to 96 hours or more. Because the foam is strong and flexible, a single box can withstand 500 or more reuse cycles, far surpassing disposable EPS coolers.

Core Material Properties and Chemical Resistance

EPP’s unique properties stem from its closed cell foam structure and polypropylene chemistry. Each bead is sealed, so the material does not absorb water and remains buoyant even in humid environments. The polymer chains resist swelling or degradation when exposed to oils, greases, acids and many solvents. Industrial tests show that EPP is rated “good” against a broad spectrum of chemicals, including acetic acid, acetone and alkaline solutions. Its heat tolerance ranges from –40 °C to +110 °C, and it melts only above 160 °C, enabling sterilization with hot water without deforming.

| Property | EPP Foam (chemical resistant box) | Significance for you |

| Chemical resistance | Resists oils, acids and many solvents | Prevents contamination and protects shipments from spills |

| Temperature range | Operates from –40 °C to +110 °C | Suitable for frozen foods, vaccines and hot meals without warping |

| Moisture absorption | Non porous closed cell structure absorbs < 0.3 % moisture | Maintains insulation even in humid or wet environments |

| Impact resilience | Returns to shape after multiple impacts; 500 + reuse cycles | Reduces breakage and allows long term reuse |

| Recyclability | 100 % recyclable and reusable | Supports sustainability goals and lowers total cost of ownership |

Practical tips and suggestions

Handling potential chemical spills: When shipping reagents or oily foods, choose an EPP box with thick walls and a tight fitting lid. Its chemical resistance prevents leaks from degrading the foam.

Extreme climate shipments: For cross country journeys lasting 48–72 hours, pair a thick EPP box (1.5 inches of foam or more) with VIP panels to extend hold time to 96 hours. Pre cool the box and contents to maximize performance.

Maximizing reuse: Clean your box with mild detergents after each trip; the non porous surface makes it easy to remove residues. Track each container’s usage and inspect for cracks so you can reuse it hundreds of times.

Real world case: A pharmaceutical distributor adopted Tempk’s EPP boxes and eliminated vaccine spoilage, reducing annual losses from US$1.2 million to zero over 18 months. The durability and chemical resistance of the containers meant they could be cleaned and reused without compromising safety, demonstrating the return on investment.

Which Industries Benefit from Chemical Resistant EPP Boxes?

Chemical resistant EPP boxes are used across pharmaceuticals, food & beverage, e commerce, electronics and automotive packaging. Their ability to maintain narrow temperature ranges, resist chemical contamination and absorb impacts makes them versatile. Pharmaceutical logistics demand 2 – 8 °C stability and adherence to Good Distribution Practice; EPP containers maintain these temperatures for 72 hours and can be equipped with IoT sensors for monitoring. The World Health Organization lists cold boxes and insulated containers as critical equipment for vaccine distribution, and plastics such as EPP and EPS comprise about 74 % of pharmaceutical cold chain packaging. The market for pharmaceutical cold chain packaging is projected to reach US$75 billion by 2032, underscoring demand for durable, reusable containers.

In food delivery and e commerce, online grocery orders and meal kits have surged since the pandemic. Compact EPP boxes keep food safe below 4 °C for up to 72 hours and feature foldable designs that collapse flat for return shipping. The Suneco Packaging guide identifies standard boxes, custom shaped boxes, stackable boxes and VIP cooler boxes. Choosing the right type protects delicate cakes or bottles and optimizes warehouse space. In electronics and automotive packaging, EPP’s impact absorption and chemical resistance shield components from shocks and oils, while its lightweight structure reduces shipping costs.

Industry specific applications

Pharmaceutical cold chain: EPP boxes maintain vaccines and biologics within 2–8 °C for 72 hours, and hybrid designs with VIP panels extend stability to 5 days. They can integrate Bluetooth or RFID sensors to transmit temperature and location data, enabling compliance with FDA and EU regulations. Because EPP resists moisture and chemicals, it preserves sterile conditions during transport.

Food & beverage delivery: Restaurants, farms and meal kit companies use EPP boxes to ship steaks, sushi and produce. The containers compress down when empty and offer stackable designs to optimize pallet space. EPP’s moisture resistance prevents condensation from damaging packaging, and its chemical stability means oils or sauces will not degrade the foam.

Electronics and sensitive equipment: For delicate electronics, automotive parts or medical devices, EPP boxes provide cushioning and chemical protection. The foam absorbs shocks and resists oils and solvents, making it ideal for shipping circuit boards or engine components. Custom molds ensure snug fit and minimize movement during transit.

| Industry | Key requirement | How a chemical resistant EPP box helps |

| Pharmaceuticals | Maintain 2–8 °C; comply with cGMP/GDP; prevent contamination | Holds temperature for 72–96 h; integrates sensors for monitoring; resists chemical spills and moisture |

| Food & e commerce | Keep food below 4 °C; minimize waste; optimize space | Insulates for up to 72 h; foldable and stackable designs save space; moisture resistant surfaces prevent condensation |

| Electronics & automotive | Shock absorption; protection from oils & solvents | EPP absorbs impacts and regains shape; chemical resistance shields components from oils |

Practical tips and suggestions

Pharmaceutical trials: For clinical trial shipments, use hybrid EPP/VIP boxes and attach Bluetooth loggers to track temperature excursions.

Meal kit delivery: Choose stackable or foldable EPP boxes when delivering multiple orders per day. Pre cool gel packs and fill void spaces to minimize air flow.

Electronic equipment: For sensitive electronics or auto parts, customize internal inserts to hold items securely. Clean boxes with mild detergents after each trip to remove any oily residue.

Case study: An online grocery retailer switched to foldable EPP boxes. The collapsible design reduced return shipping volume by 40 %, and stackable walls improved warehouse capacity. Moisture resistance prevented condensation from damaging labels, enhancing customer satisfaction.

How to Choose and Maintain a Chemical Resistant EPP Box

Selecting the right EPP box depends on shipment duration, product sensitivity and regulatory requirements. For short shipments (< 24 hours), a standard EPP box with gel packs may suffice. For medium durations (48–72 hours), choose a thick walled EPP container (1.5 inches or more) and pair it with dry ice or VIP inserts for frozen goods. In closed loop systems, track each container’s trips and schedule cleaning after every use—foldable boxes are easy to return and store.

When matching box types to products, consider the Suneco Packaging categories: standard boxes, custom shaped boxes, stackable boxes and VIP cooler boxes. Custom shapes with inserts protect fragile goods like glass vials or cakes, while stackable boxes lock together to prevent shifting. VIP cooler boxes combine EPP with vacuum panels for extended hold times.

Packing and handling best practices

Pre cool everything before loading: refrigerate products, gel packs and the box itself. Underestimate refrigerant quantity at your peril—use more gel packs than you think necessary. Fill void spaces with void fillers or additional packs to minimize air circulation and temperature gradients. Seal the box properly by ensuring latches and gaskets are closed; some foldable boxes require extra attention at hinges. Attach a temperature logger or Bluetooth sensor to record conditions during transit, which aids compliance and quality assurance. After each use, clean the box with mild detergents; EPP’s non porous surface resists chemicals and is easy to sanitize.

Selection and maintenance table

| Selection criterion | Recommendation | Why it matters |

| Shipment duration | < 24 h: standard EPP box; 48–72 h: thick EPP with dry ice/VIP; > 72 h: hybrid EPP/VIP system | Matching insulation to transit time ensures products remain within safe temperatures |

| Product fragility | Use custom shaped boxes with inserts for fragile items | Prevents movement and breakage during transport |

| Return logistics | Choose foldable or stackable boxes to reduce return volume | Saves warehouse space and reduces shipping costs |

| Regulatory compliance | Attach temperature loggers and ensure boxes meet cGMP/GDP standards | Supports audits and prevents costly temperature excursions |

| Cleaning and reuse | Clean with mild detergent; inspect for damage after each trip | Maximizes lifespan and maintains hygiene |

Practical tips and suggestions

Short haul deliveries: For local deliveries within a city, opt for lighter EPP boxes and focus on secure sealing rather than extra VIP panels.

High value medicines: Invest in VIP hybrid boxes and real time monitoring to safeguard gene therapies that require –70 °C storage. The higher upfront cost is offset by avoiding spoilage fines.

Reuse management: Implement a return for reuse program and educate staff on proper cleaning; track each container’s cycles to plan replacement before end of life.

Example: A seafood exporter added dry ice to thick EPP boxes for cross country deliveries, reducing rejected shipments from 15 % to 0.3 %. Careful refrigerant calculation and proper sealing ensured the fish arrived frozen without chemical contamination.

2025 Latest Developments and Trends in Chemical Resistant EPP Packaging

Trend overview

The chemical resistant EPP box market is evolving rapidly as sustainability and technology converge. Archive Market Research values the EPP insulation box market at about US$2 billion in 2025 and projects a 7 % compound annual growth rate (CAGR) to 2033. Four forces drive this growth:

E commerce and last mile delivery: The boom in online grocery and pharmacy services increases demand for reliable cold chain solutions.

Regulatory pressure: Stringent food safety and pharmaceutical guidelines mandate validated packaging to avoid recalls.

Sustainability commitments: Corporations seek recyclable and reusable packaging to reduce waste; EPP’s 100 % recyclability offers an attractive alternative to EPS.

Technological innovation: Manufacturers integrate IoT sensors and smart tracking into EPP containers, and hybrid designs combine EPP with VIP or phase change materials for extended performance.

Latest progress at a glance

Hybrid insulation systems: Combining VIP panels with EPP foam delivers up to five days of temperature stability, ideal for long haul or remote deliveries.

Smart sensors: Built in Bluetooth trackers send alerts when temperatures drift outside safe ranges, preventing spoilage and simplifying audits.

Circular logistics programs: Take back schemes collect used boxes, clean them and remold the material into new containers, supporting a circular economy.

Market insights and regional trends

The EPP insulation box market is concentrated in North America and Europe, but Asia–Pacific shows the fastest growth due to rising incomes and expanding cold chain infrastructure. Food applications represent roughly 60 % of the market, while pharmaceuticals account for about 25 %. Innovation focuses on lighter, stackable designs and recycled materials to reduce cost and carbon footprint.

Beyond EPP, the broader cold chain packaging industry is booming. According to Towards Packaging, the market size was US$34.28 billion in 2024 and is projected to reach US$89.84 billion by 2034, growing at an 11.3 % CAGR. While expanded polystyrene (EPS) dominated 2024 share, the shift toward reusable materials like EPP and vacuum insulated panels indicates a long term move away from single use plastics.

Practical takeaways

Stay ahead of regulations: Monitor upcoming packaging laws. The rise of extended producer responsibility (EPR) means companies may be required to ensure their packaging is recyclable or reusable.

Invest in smart logistics: Integrate temperature and location sensors into your EPP boxes to gain real time visibility and automate compliance reporting.

Adopt circular programs: Partner with suppliers offering take back schemes; recycling EPP foam into new boxes reduces raw material demand and demonstrates sustainability leadership.

Frequently Asked Questions

What chemicals are EPP boxes resistant to? EPP foam resists oils, greases, acids and many solvents. Industry tests show good resistance to acetic acid, acetone and alkaline solutions. It is also resistant to oil and water, making it suitable for contaminated or messy shipments.

How long can a chemical resistant EPP box maintain temperature? Standard EPP boxes keep contents cold for 72 hours with gel packs and up to 96 hours when equipped with VIP panels. Pre cooling the box and using sufficient refrigerants extend hold time.

How many times can an EPP box be reused? A single EPP box can withstand 500 or more reuse cycles with proper cleaning and inspection. Foldable designs make return logistics economical.

Are chemical resistant EPP boxes safe for food contact? Yes. Expanded polypropylene is non toxic, food grade and resistant to moisture and chemicals. Its closed cell structure prevents bacteria growth and makes it easy to clean.

Can EPP boxes be recycled? EPP foam is technically 100 % recyclable, and many manufacturers operate take back programs. However, current infrastructure recycles only about 15–20 % of post consumer EPP. Participating in closed loop programs helps recover material and reduce waste.

What’s the difference between EPP, EPS and EPE foam boxes? EPP offers the best elastic recovery and chemical resistance. Compared with EPS, which tends to crack and lose insulation after impacts, EPP withstands repeated hits and retains performance. EPE is lighter but provides lower insulation and energy absorption. EPP’s higher upfront cost is offset by longer service life and lower total cost of ownership.

Summary & Recommendations

Chemical resistant EPP boxes combine superior insulation, durability and chemical stability to protect perishable goods. Their closed cell foam maintains cold or frozen temperatures for 72–96 hours, resists oils and solvents, and withstands 500 + reuse cycles. EPP is 100 % recyclable and supports circular logistics programs, making it a sustainable alternative to single use EPS. Demand is growing rapidly, driven by e commerce expansion, regulatory pressure and technological innovation.

Actionable advice

Audit your current packaging: Identify where temperature excursions or chemical contamination occur and calculate spoilage costs.

Choose the right EPP box: Match box type (standard, custom shaped, stackable, VIP hybrid) to your product’s fragility and transit time.

Optimize packing: Pre cool boxes, use ample gel packs, fill voids and seal properly. Attach sensors to monitor conditions.

Implement a return program: Clean and inspect boxes after each use; foldable designs simplify returns and storage.

Embrace innovation: Explore hybrid insulation and smart tracking technologies to extend performance and improve compliance.

About Tempk

We are Tempk, a leading innovator in cold chain packaging solutions. Our R&D team combines advanced materials science with user centric design to create compact EPP boxes that provide up to five days of temperature stability through hybrid insulation. We integrate IoT sensors to deliver real time temperature and location data, enabling proactive interventions and regulatory compliance. Our commitment to circular logistics means we collect used boxes, recycle the foam and mold new containers, reducing waste and supporting a greener supply chain. Whether you ship vaccines, gourmet meals or laboratory samples, we offer customizable, sustainable packaging to help your business thrive.

Ready to upgrade your cold chain? Reach out to our team for a consultation on chemical resistant EPP boxes and discover how our solutions can reduce spoilage, lower costs and meet your sustainability goals.