How to Choose the Best Custom Insulated Box Liner for Your Cold Chain Needs in 2026?

Introduction

Choosing the right custom insulated box liner is crucial for ensuring your temperature-sensitive products remain protected throughout the shipping process. Whether you’re shipping pharmaceuticals, food products, or electronics, selecting the right insulated box liner can optimize your cold chain logistics. This guide will walk you through key considerations when selecting the perfect custom insulated box liner for your business, focusing on the latest trends and performance standards for 2026.

This Article Will Help You Answer:

What is a custom insulated box liner, and why is it critical for your cold chain logistics?

How to choose the right materials for custom-sized liners?

Key factors to consider when selecting an OEM for custom liners

Trends in cold chain packaging and the future of custom liners in 2026

What Is a Custom Insulated Box Liner, and Why Should You Choose One?

A custom insulated box liner is a tailored solution designed to meet the specific temperature and size requirements of your shipment. Unlike standard liners, which come in predetermined sizes, custom liners are designed to perfectly fit your products and shipping conditions. This helps minimize air gaps, enhances thermal performance, and ultimately ensures better product protection.

Why Custom Liners Matter:

Perfect Fit: Custom liners reduce empty space, improving insulation efficiency and minimizing the risk of temperature excursions.

Optimized Performance: Custom liners are designed to meet specific temperature ranges, ensuring reliable protection throughout transit.

Sustainability: You can choose eco-friendly materials to align with your sustainability goals while maintaining top-notch insulation.

Cost-Effectiveness: By reducing material waste and improving thermal efficiency, custom liners can help lower overall shipping costs.

Key Factors to Consider When Choosing Custom Insulated Box Liners

1. Material Selection for Custom Insulated Box Liners

The material you choose for your custom insulated box liner plays a significant role in the overall performance. Common materials include:

| Material Type | Thermal Performance | Best Use Case |

|---|---|---|

| Foil Bubble Liners | Good thermal resistance | Short-to-medium shipping durations |

| EPS (Expanded Polystyrene) | High thermal resistance | Longer shipments and perishable goods |

| Polyurethane Foam | Very high thermal resistance | Long-distance and temperature-sensitive shipments |

| Paper-Based Liners | Moderate thermal resistance | Eco-friendly, shorter transit |

Each material has its advantages and trade-offs depending on the duration of the shipment and the sensitivity of the goods. Foil bubble liners are ideal for short transit times, while EPS and polyurethane foam provide better insulation for longer periods.

2. Fit and Size Customization

Custom insulated box liners must fit the packaging exactly to ensure optimal thermal performance. Even slight gaps between the liner and the box can lead to temperature fluctuations and increased energy consumption. Properly sized liners reduce the risk of product spoilage and minimize the need for additional refrigerants, which helps lower packaging and shipping costs.

Here’s how to select the right size for your custom liner:

Measure your product’s dimensions: Ensure that the liner matches the box’s interior size without excessive air gaps.

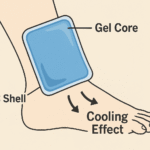

Account for refrigerants: If you’re using gel packs or dry ice, make sure the liner accommodates these cooling elements without crowding your products.

Precision: A snug fit ensures that no space is wasted and that the insulation can perform efficiently throughout the shipment.

3. Temperature Hold Time Requirements

Different products require different temperature hold times during shipment. Here’s a general guide to selecting custom insulated box liners based on your transit needs:

Short Shipments (<24 hours): Lighter, close-fit liners are often sufficient.

Medium Transit (24-72 hours): Mid-thickness custom liners with structured insulation work best.

Long Durations (>72 hours): Thicker, multi-layer liners with minimal air gaps provide the most reliable protection.

4. Durability and Moisture Resistance

For products like pharmaceuticals, food, or electronics, it’s crucial that your custom insulated box liners are not only thermally efficient but also durable enough to withstand the rigors of transit. Look for materials that offer:

Moisture resistance: Preventing moisture buildup ensures your products stay protected and free from potential damage.

Puncture and tear resistance: Liners should remain intact and not break under pressure during handling.

5. Customization Options

A good OEM supplier will offer various customization options to meet your specific needs. Some of the features to look for include:

Branding: Custom liners can be printed with your brand logo or design, ensuring professional packaging and enhancing customer experience.

Recyclability: Eco-friendly materials can help you meet sustainability goals without compromising insulation performance.

Multi-layer insulation: Some custom liners combine different materials, such as reflective layers and foam inserts, for enhanced performance.

How Does Custom Size Improve Thermal Efficiency?

The core benefit of custom size insulated box liners lies in their ability to perfectly fit the packaging, reducing empty space and preventing temperature variations. Think of thermal insulation like clothing: a custom-fitted jacket retains heat much better than a loose, ill-fitting coat. Similarly, a perfectly sized liner keeps your product securely insulated, extending temperature hold times and ensuring the product’s integrity.

Benefits of Custom Size for Thermal Efficiency:

Minimized heat transfer: A snug fit reduces convective heat flow, prolonging internal temperature stability.

Reduced thermal leakage: Gaps in a standard liner create hot spots or cold zones, leading to spoilage and waste. Custom-sized liners eliminate this issue.

Latest Trends in Custom Insulated Box Liners for 2026

1. Sustainability and Eco-Friendly Materials

In 2026, businesses are increasingly adopting eco-friendly packaging solutions. Custom insulated box liners made from recyclable materials like paper-based insulation or biodegradable foams are gaining popularity. These materials provide reliable thermal protection while helping businesses meet their sustainability goals.

2. Smart Packaging and Temperature Monitoring

The integration of smart technology into custom insulated liners is a growing trend. Sensors embedded in liners can monitor temperature changes during transit, providing real-time data to ensure product safety. This technology is particularly beneficial for sensitive products like pharmaceuticals, where maintaining strict temperature ranges is crucial.

3. Multi-Layer Insulation for Enhanced Performance

Multi-layer custom insulated box liners are designed to offer superior thermal protection by combining materials like reflective films, foam, and paper insulation. This layering approach provides high R-value (thermal resistance) and ensures that your products are protected even during long-duration shipments.

4. Lean Packaging Designs

Smarter and more efficient packaging designs are emerging. These liners are optimized for storage and reduce freight costs by minimizing wasted space while maintaining effective insulation. Such designs are especially beneficial for e-commerce companies looking to streamline their packaging processes.

How to Evaluate the Quality of Custom Insulated Box Liners

1. Sample Testing

Before making a large order, request samples from your supplier. Testing the liners under real-world conditions will allow you to assess their thermal performance, durability, and fit. Conduct temperature simulations and stress tests to ensure the liners meet your standards.

2. Certifications and Compliance

For certain industries like food or pharmaceuticals, compliance with industry standards is critical. Ensure your supplier provides documentation that proves the liners meet regulatory requirements such as FDA approval or ISO certifications.

3. Long-Term Performance

Look for liners that provide reliable performance over multiple shipments. The best custom liners are designed for repeated use and must withstand the challenges of long-term cold chain logistics.

FAQs About Custom Insulated Box Liners

Q1: Why should I choose custom size insulated box liners over standard liners?

Custom size liners ensure a perfect fit for your products, improving thermal efficiency, reducing waste, and preventing temperature excursions that can damage your goods.

Q2: How can I determine the right size for my custom liners?

Measure your product and box dimensions precisely. Allow minimal space for refrigerants and ensure the liner fits snugly around the product to eliminate gaps and improve insulation efficiency.

Q3: Can custom insulated liners reduce shipping costs?

Yes, by reducing empty space and optimizing material use, custom liners help lower shipping costs by improving packaging density and reducing freight weight.

Conclusion: Why Custom Size Insulated Box Liners Are Essential for Your Cold Chain Operations

In conclusion, custom size insulated box liners are a game-changer for businesses involved in cold chain logistics. They offer improved thermal efficiency, reduced packaging waste, and better product protection. By selecting the right custom liner, businesses can ensure their temperature-sensitive products remain safe and intact throughout transit.

Next Step: Contact a trusted supplier of custom insulated box liners to request samples and start optimizing your cold chain logistics for 2026.

About Tempk

At Tempk, we specialize in providing high-performance, custom insulated box liners tailored to your cold chain needs. Our solutions ensure reliable thermal protection, reduce waste, and meet sustainability goals. Contact us today to explore how our custom liners can improve your logistics efficiency.