As demands for food freshness and pharmaceutical safety continue to rise, cold chain logistics technology is rapidly advancing, leading to the emergence of various new cooling products. Among these, Dry Ice Packs for Shipping are widely used and garner significant attention. Compared to other ice packs available on the market, Dry Ice Packs for Shipping, known for their environmental friendliness, safety, and efficiency, play an increasingly vital role in the transportation of food, pharmaceuticals, and biological products.

What are Dry Ice Packs for Shipping?

Dry Ice Packs for Shipping, also known as water-absorbing ice packs or dry-type ice packs, are typically manufactured using Super Absorbent Polymer (SAP) combined with non-woven fabric or permeable film materials. When immersed in water, the SAP rapidly absorbs a large amount of water, forming a gel substance. Once frozen, it provides stable and long-lasting low temperatures.

Differences Between Dry Ice Packs and Other Ice Packs

The market offers various ice packs, including traditional gel packs and water ice packs. Dry Ice Packs for Shipping possess distinct advantages over these alternatives:

- Superior Temperature Control Stability: Traditional gel packs become very hard when frozen and their cooling performance can degrade quickly. In contrast, Dry Ice Packs for Shipping retain some flexibility after freezing, allowing them to conform more tightly to products and enhance cooling efficiency.

- Lightweight and Space-Saving: Unused Dry Ice Packs for Shipping are lightweight and compact, significantly saving transportation and storage space, whereas traditional ice packs occupy more space even when not in use.

- Enhanced Environmental Safety and Safety: The primary materials in Dry Ice Packs for Shipping are non-toxic SAP and water. Leakage does not cause environmental pollution, whereas dealing with leaks from traditional gel pack materials can be problematic.

Structure and Principle of Dry Ice Packs for Shipping

Dry Ice Packs for Shipping generally consist of three main components:

- Outer Layer: Typically made of PE film or water-permeable non-woven fabric, providing permeability while ensuring strength.

- Super Absorbent Polymer (SAP) Layer: Rapidly absorbs and locks in water to form a stable gel.

- Leak-Proof Composite Film Layer: Provides an additional layer of safety to prevent leaks during transportation.

To use, simply immerse the Dry Ice Pack for Shipping in water for several minutes. The SAP swells to form a gel, which is then frozen for use.

Application Areas of Dry Ice Packs for Shipping

Food Transportation

Dry Ice Packs for Shipping are extensively used in food transportation to provide a stable low-temperature environment for fresh fruits, vegetables, meats, and seafood, effectively extending product shelf life.

Pharmaceutical Transportation

Pharmaceutical cold chains demand strict temperature control. Due to their excellent temperature control performance, Dry Ice Packs for Shipping are widely employed in the logistics transportation of vaccines, biologicals, and blood products.

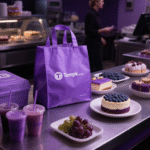

E-commerce and Meal Delivery

Suitable for various coolers and insulated bags, Dry Ice Packs for Shipping meet both short and long-distance delivery requirements and are widely used in e-commerce logistics and the meal delivery industry.

Advantages of Dry Ice Packs for Shipping

Safety and Environmental Friendliness

Non-toxic and harmless, Dry Ice Packs for Shipping pose no environmental risk if leakage occurs and are simple to dispose of.

Convenience and Efficiency

Easy to use: simply soak and freeze, requiring no complex procedures.

Flexibility and Versatility

Remain somewhat flexible after freezing, allowing them to conform better to the shape of items and improve cooling effectiveness.

High Cost-Effectiveness

Low-cost and reusable, Dry Ice Packs for Shipping offer significant economic benefits.

Usage Tips for Dry Ice Packs for Shipping

- Ensure Thorough Soaking: Soak for at least 15 minutes to ensure complete water absorption.

- Freeze Completely: Ensure packs are fully frozen before use.

- Strategic Placement: Arrange the position and quantity scientifically to achieve optimal temperature control results.

Development Trends for Dry Ice Packs for Shipping

With the continuous growth in cold chain logistics demand, Dry Ice Packs for Shipping are expected to evolve in the following directions:

- Material Innovation: Development of more efficient absorbent materials.

- Smart Temperature Control: Integration with IoT technologies for precise temperature monitoring.

- Customized Solutions: Provision of personalized temperature control solutions.

Dry Ice Packs for Shipping, with their safety, environmental benefits, and efficiency, have become essential products in the cold chain logistics sector. As technology advances, their performance and applications will further expand, providing safer and more efficient temperature-controlled transportation solutions.