Can Dry Ice Packs Be Used with Solid CO₂ Dry Ice? What Ventilation Precautions Are Needed?

In the cold chain logistics industry, ensuring the safe and efficient transport of temperature-sensitive goods is critical. A common question arises: can dry ice packs be used with solid CO₂ dry ice, and what safety precautions must be followed? This article will provide you with in-depth guidance on how to safely combine these two cooling methods, address necessary ventilation measures, and explain the best practices for maintaining an optimal cold chain.

-

How can dry ice packs be effectively used with solid CO₂ dry ice?

-

What ventilation measures are critical when using both types of dry ice?

-

How should you store and transport goods using both forms of dry ice safely?

-

What are the best practices for industries such as pharmaceuticals and food transport?

Can Dry Ice Packs Be Used with Solid CO₂ Dry Ice Effectively?

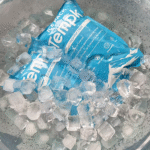

Dry ice packs and solid CO₂ dry ice both play pivotal roles in cold chain logistics, but they work in slightly different ways. Dry ice packs are essentially gel-based containers that are frozen using CO₂, providing steady and controllable cooling. In contrast, solid CO₂ dry ice directly sublimates from a solid to gas at a temperature of -109.3°F (-78.5°C), offering intense cooling.

So, can these two types of cooling agents work together? Yes, they can. The combination of dry ice packs and solid CO₂ dry ice can offer enhanced flexibility and control over temperature. Dry ice packs provide a stable, long-lasting cooling effect, while solid CO₂ dry ice offers powerful bursts of extreme cold when required. By strategically using both, you can create a more robust cooling environment for long-term storage or transport.

Why Combine Both Dry Ice Packs and Solid CO₂ Dry Ice?

Using both cooling methods gives you better control over the temperature management, especially during long-distance shipments. Dry ice packs can keep items at a steady temperature, while solid CO₂ dry ice can handle extreme cooling. This combination is beneficial for industries that require precise temperature maintenance, such as pharmaceuticals and food logistics.

Real-World Example: A pharmaceutical company successfully used both dry ice packs and solid CO₂ dry ice during a long-haul shipment of vaccines, ensuring a controlled cooling environment for over 48 hours.

Ventilation Safety: Why Is It Crucial When Using Dry Ice?

The critical concern when using solid CO₂ dry ice is the sublimation process, where solid CO₂ turns directly into carbon dioxide (CO₂) gas. This gas can displace oxygen in confined spaces, leading to asphyxiation and potential danger to people around it. Proper ventilation is essential to prevent the buildup of CO₂ gas and ensure that the space remains safe.

Ventilation Guidelines

-

Use Well-Ventilated Containers: Always opt for coolers and storage units that allow CO₂ gas to escape. Never seal containers tightly, as this can cause pressure buildup, leading to potential rupture.

-

Ensure Air Circulation: For larger containers, vented lids or vent holes allow sublimating CO₂ gas to escape. When transporting dry ice, ensure adequate airflow in the vehicle or storage area.

-

CO₂ Detectors: In enclosed spaces such as laboratories, warehouses, or transport vehicles, CO₂ detectors are critical to monitor gas buildup. These detectors can alert you if the CO₂ levels reach unsafe limits.

-

Avoid Airtight Containers: Containers used for storing or transporting dry ice must not be airtight. Sealed units will trap CO₂ gas, causing dangerous pressure increases.

Best Practices for Storing and Transporting Goods with Dry Ice Packs and Solid CO₂ Dry Ice

To safely transport goods using both dry ice packs and solid CO₂ dry ice, follow these best practices:

1. Layering the Dry Ice

-

Place the solid CO₂ dry ice at the bottom of the cooler. This ensures that cold air sinks, helping to maintain consistent cooling.

-

Position the dry ice packs above to create a more gradual cooling effect, preventing direct contact between goods and the extremely low temperatures of the solid CO₂ dry ice.

2. Use Insulated and Vented Containers

-

Select coolers designed for CO₂ sublimation with built-in ventilation systems. These containers will allow gas to escape safely, keeping the temperature steady and ensuring that the pressure does not build up.

3. Avoid Fully Sealed Containers

-

Make sure there is a slight gap in the lid or opening of the cooler. This allows CO₂ gas to vent out as the dry ice sublimates.

4. Label Containers Clearly

-

For safe transport, label containers with a “Dry Ice” symbol, and ensure compliance with shipping regulations.

5. Store in a Cooler Environment

-

Keep your cooler in a cool area to prevent excessive sublimation from heat sources or direct sunlight, which could cause the dry ice to evaporate faster.

Industry-Specific Considerations for Using Dry Ice

Different industries have unique requirements when it comes to using dry ice. Here’s how dry ice packs and solid CO₂ dry ice are applied in specific industries:

| Industry | Best Practices | Key Considerations |

|---|---|---|

| Pharmaceuticals | Use both for controlled shipments of temperature-sensitive products. | Track temperature with real-time data loggers. |

| Food Transport | Layer dry ice packs and solid CO₂ for perishable goods. | Regularly monitor CO₂ levels, especially on long trips. |

| Biotech | Insulate coolers and combine both types for long-term cooling. | Always use CO₂ detectors during transportation. |

| Medical Supplies | Use insulated, ventilated storage containers for safety. | Prevent direct contact with dry ice to avoid product damage. |

Example of Best Practice

In one case, a biotech company used a combination of dry ice packs and solid CO₂ dry ice to transport vaccines across international borders. By layering the two, they successfully maintained a steady temperature for over 72 hours, ensuring the vaccines’ quality and viability throughout transit.

2025 Trends in Dry Ice Usage and Cold Chain Logistics

As we move into 2025, the cold chain logistics industry is evolving with several key trends:

-

Sustainable Cold Chain Solutions: There is a growing focus on eco-friendly dry ice solutions and alternative cooling materials. Innovations such as biodegradable dry ice materials and CO₂ capture systems are being explored to reduce environmental impact.

-

Smart Containers and Monitoring Systems: Smart containers with integrated temperature sensors and CO₂ monitoring systems are transforming how companies manage and track cold chain shipments in real-time.

-

Phase-Change Materials (PCMs): PCMs are emerging as a new alternative to traditional gel packs, providing more precise temperature control and reusability, aligning with sustainability goals.

What Does This Mean for Your Cold Chain Operations?

These developments are shaping the future of cold chain logistics, and businesses that embrace these trends will have a competitive edge, benefiting from improved efficiency, sustainability, and safety.

Commonly Asked Questions (FAQ)

Q1: Can dry ice packs be used in a sealed cooler with solid CO₂ dry ice?

A1: No, using sealed coolers is unsafe as it prevents gas from escaping. This can cause pressure buildup, leading to potential hazards. Always opt for vented coolers.

Q2: How do I know if CO₂ levels are unsafe?

A2: Elevated CO₂ levels can cause symptoms such as dizziness, shortness of breath, and confusion. Install CO₂ detectors in enclosed spaces to monitor these levels.

Q3: How should dry ice be disposed of?

A3: Never dispose of dry ice in sealed containers or drains. Allow it to sublimate in a well-ventilated area, preventing hazardous situations.

Conclusion and Recommendations

In conclusion, combining dry ice packs with solid CO₂ dry ice is an effective way to maintain a consistent cold chain for temperature-sensitive products. However, safety precautions, particularly with ventilation, are critical. Be sure to use appropriate vented coolers, monitor CO₂ levels, and carefully package your goods to prevent safety hazards.

Action Steps:

-

Assess your needs: Determine if using both dry ice packs and solid CO₂ dry ice fits your product’s transport requirements.

-

Ensure compliance: Always follow local regulations for dry ice handling and transportation.

-

Plan ahead: Invest in smart cold chain solutions to stay ahead of the curve and ensure the safety of your goods.

About Tempk

At Tempk, we specialize in cold chain logistics solutions, offering advanced packaging and monitoring systems tailored to industries such as pharmaceuticals, food transport, and biotech. Our products are designed to ensure that your sensitive goods remain at the right temperature throughout their journey.

Take the next step: Contact Tempk today for a personalized consultation on how we can improve your cold chain operations.