Shipping goods with dry ice is essential for maintaining low temperatures during transit, but it’s critical to follow the correct safety protocols. One common question is: Can I tape a dry ice bag shut? The short answer is no. Taping a dry ice bag shut is unsafe because it traps carbon dioxide gas, leading to pressure buildup and potentially dangerous consequences. Read on to understand the science behind dry ice, the risks of improper sealing, and the safest practices for dry ice packaging in 2025.

-

Why isn’t taping a dry ice bag shut safe?

We’ll explain how sublimation creates gas pressure and why this leads to shipping risks. -

How to properly close a dry ice bag?

Step-by-step guidance on sealing dry ice bags safely. -

Latest 2025 dry ice packaging regulations?

Understand new industry standards for shipping with dry ice.

Why Can’t You Tape a Dry Ice Bag Shut?

Dry ice sublimates into carbon dioxide gas, and when it’s sealed in an airtight bag, the gas cannot escape. This causes pressure to build inside the package, which can lead to a rupture or even an explosion. As CO₂ gas expands, it creates significant pressure that may deform or burst the container.

Important Note: Dry ice sublimes directly into gas, reaching a temperature of -109.3°F (-78.5°C). As a result, each kilogram of dry ice produces 541 liters of gas at room temperature. Without proper ventilation, the sealed package risks rupture due to rising pressure

Suffocation Hazard:

As carbon dioxide builds up in confined spaces, it can displace oxygen, creating a risk of suffocation. This is particularly dangerous in sealed shipping containers or airplanes, where CO₂ buildup can lead to health risks like dizziness or unconsciousness.

Proper Packaging Techniques for Dry Ice

To ensure safe and compliant shipping of dry ice, adhere to the following best practices:

-

Use Ventilated Bags or Containers:

-

Dry ice bags should always have ventilation holes to allow gas to escape.

-

Opt for ventilated dry ice bags or insulated containers that promote safe gas release while maintaining the cold temperature.

-

-

Insulate the Package:

-

Insulated boxes slow the sublimation rate and keep the dry ice colder for longer periods. However, ensure these boxes are still ventilated for gas to escape.

-

-

Label Appropriately:

-

Packages containing dry ice should be properly labeled with the UN 1845 identifier and a Class 9 hazard label. This ensures compliance with DOT and IATA regulations.

-

-

Fill Empty Spaces:

-

Prevent dry ice from shifting during transit by using packing materials like loose fill or crumpled paper.

-

Key Tip: Always monitor sublimation rates to make sure your dry ice remains effective throughout the journey.

How to Avoid Dry Ice Shipping Risks in 2025

Advances in packaging have made it easier to safely transport dry ice. Here’s a summary of 2025 innovations:

-

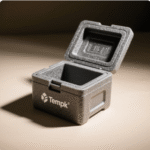

Smart Packaging Solutions: Temperature and CO₂ sensors are integrated into dry ice shipments, ensuring accurate tracking of internal conditions. This helps identify issues like gas buildup before they cause damage.

-

Sustainable Practices: The cold chain logistics industry is adopting eco-friendly packaging options such as biodegradable dry ice bags and recyclable containers, reducing the environmental footprint of temperature-sensitive shipments.

-

Enhanced Tracking: Real-time visibility into a package’s location and temperature ensures proactive adjustments and improves compliance with regulations.

Frequently Asked Questions

Q1: Can I tape a dry ice bag shut to prevent leaks?

No. Taping a dry ice bag shut traps gas inside, creating dangerous pressure. Always fold the liner bag loosely to allow gas to vent.

Q2: How do I keep the dry ice from falling out if I don’t tape the bag?

Use a properly sized liner bag and fold it neatly. Secure the opening loosely without taping to maintain ventilation.

Q3: Do I need to label a dry ice shipment?

Yes. Labeling is mandatory. The package should include UN 1845, hazard class 9, and the net weight of the dry ice.

Conclusion and Recommendations

Sealing a dry ice bag shut is a safety risk that can lead to pressure buildup, explosions, and asphyxiation hazards. Always use ventilated containers, insulate the package properly, and adhere to labeling requirements for safe shipping. Stay updated with the latest 2025 regulations and utilize smart packaging solutions to ensure safety and compliance.

Next Steps:

-

Check your packaging process: Ensure ventilation in dry ice bags and proper sealing of outer containers.

-

Use smart dry ice containers that allow for real-time temperature monitoring.

-

Consult experts for guidance on dry ice shipping best practices and regulatory compliance.

About Tempk

At Tempk, we specialize in cold chain logistics and provide cutting-edge temperature-sensitive shipping solutions. Our dry ice packaging products ensure safe, compliant, and eco-friendly transport for industries like pharmaceuticals and biotech.

Consult with us today for tailored dry ice packaging solutions that meet your shipping needs.