How Does Cold Chain Management Ensure Pharmaceutical Safety in 2025?

Updated: November 10, 2025

In the pharmaceutical world, maintaining correct temperatures isn’t optional — it’s a lifeline. Failure to do so can ruin vaccines, biologics and advanced therapies worth millions of dollars. In 2025 the global cold chain market for pharmaceuticals is projected to exceed US $6.6 billion, and over 85 % of biologic drugs require temperature controlpharmasource.global. You need reliable cold chain management strategies to keep your products potent, ensure regulatory compliance and build patient trust.

-

Why cold chain management is critical in modern pharmaceuticals. Learn how temperature affects drug potency and why up to half of vaccines spoil annually due to improper storagepharmasource.global.

-

What technologies improve cold chain visibility and control. Explore IoT sensors, data loggers, GPS trackers and cloud platforms that provide real‑time monitoring.

-

Which packaging innovations protect temperature‑sensitive drugs. Understand phase‑change materials, insulated shippers and smart reefers that maintain thermal stabilitytempaidcoldchain.com.

-

How to meet regulatory requirements and reduce risk. Discover best practices to align with FDA, EMA and WHO guidelinesmaersk.com and avoid costly temperature excursions.

-

What future trends will shape cold chain logistics by 2025 and beyond. See how AI, blockchain and sustainability initiatives are transforming logisticsmaersk.com.

Why Is Cold Chain Management Critical for Modern Pharmaceuticals?

Direct Answer: protecting potency and public health

Cold chain management keeps pharmaceuticals within precise temperature ranges to preserve efficacy and safety. Without proper temperature control, biologics, vaccines and peptides lose potency, become unsafe or even hazardousmaersk.com. Standard vaccines must be stored between 2 °C and 8 °Camericanbiotechsupply.com, while mRNA COVID‑19 vaccines require ultra‑cold storage as low as −90 °Camericanbiotechsupply.com. Over 50 % of vaccines are wasted annually due to temperature excursionspharmasource.global, representing billions of dollars in losses and threats to public health.

Background and context

You rely on the cold chain from manufacturing to patient administration: raw materials, intermediate bulk and finished products need different temperature bands — controlled room temperature (20 °C–25 °C), refrigerated (2 °C–8 °C) and cryogenic (below −60 °C)pharmasource.global. Biologics pipeline expansion is driving this demand; more than 85 % of biologics require cold chain managementpharmasource.global. Cell and gene therapies need cryogenic storage at −150 °C or lowerpharmasource.global, while peptides such as GLP‑1 agonists require refrigerated storagepharmasource.global. Without an effective cold chain, you risk product degradation, regulatory violations and loss of consumer confidence.

Risks and consequences

| Risk | Example | Impact on you |

|---|---|---|

| Product degradation | Temperature excursions degrade vaccines and biologics | Inactive drugs, ineffective therapy and patient harm |

| Regulatory penalties | FDA, EMA and WHO require temperature documentationmaersk.com | Fines, recalls and damaged reputation |

| Financial loss | Lost inventory, restocking costs, wasted materials | Millions in losses and supply shortages |

Practical tips to protect potency

-

Map temperature requirements early. Document temperature ranges for raw materials, intermediates and finished drugs to prevent excursions during process developmentpharmasource.global.

-

Train your staff. Make sure everyone understands vaccine storage and handling; inadequate training is a major cause of cold chain failuresamericanbiotechsupply.com.

-

Prepare contingency plans. Power outages and equipment failures happen. Develop protocols and backup storage to handle emergencies.

Real case: During the global COVID‑19 vaccine rollout, mRNA vaccines required ultra‑cold storage between −90 °C and −60 °Camericanbiotechsupply.com. Companies that invested early in ultra‑low freezers and validated shipping containers ensured timely distribution and avoided spoilage. Those without adequate infrastructure faced delays and wasted doses.

What Technologies Improve Cold Chain Monitoring and Visibility?

Direct Answer: harnessing IoT sensors and real‑time data

Modern cold chain management uses sensors, data loggers, GPS trackers and cloud platforms to monitor temperature continuously. IoT‑enabled devices transmit real‑time data and send alerts when conditions deviate. They comply with FDA, WHO and EU GDP guidelines and reduce waste by enabling immediate corrective actions.

Background and context

The traditional approach of manually checking temperature charts or retrieving data loggers after delivery is no longer sufficient. The global cold chain monitoring market grew from USD 5.3 billion in 2022 to an estimated USD 35 billion in 2024, reflecting increased adoption of advanced technologies. Real‑time visibility enhances compliance, mitigates risk and speeds up release processesmaersk.com.

Technology landscape

Data loggers and IoT sensors

Data loggers are compact devices that record temperature and humidity over time. They provide historical records to demonstrate compliance but may not offer real‑time alerts. IoT‑based wireless sensors, on the other hand, transmit data continuously via Wi‑Fi, cellular or LoRaWAN networks, enabling remote access. These sensors provide predictive maintenance insights and automated alerts for deviations.

RFID and GPS trackers

RFID temperature sensors embed monitoring capabilities into tags that can be scanned automatically in warehouses and trucks. They streamline inventory management by eliminating manual data collection. GPS‑based trackers combine location and temperature monitoring for shipments in transit. They enable route optimization and real‑time interventions when shipments deviate from planned paths.

Bluetooth Low Energy (BLE) and smart reefers

BLE sensors provide short‑range temperature monitoring for warehouses and vehicles. They consume minimal power and integrate with smartphones or tablets. Smart refrigerated containers (reefers) self‑regulate temperature and offer remote monitoring, ensuring stable conditions during long‑distance transport but requiring significant energy and investment.

Cloud platforms and predictive analytics

Cloud‑based monitoring platforms aggregate data from sensors, RFID tags and trackers, offering analytics and compliance reports. At Maersk, remote container management systems and digital visibility tools provide real‑time temperature data, enabling shippers to initiate release processes earliermaersk.com. Blockchain technology creates immutable records of temperature conditionsmaersk.com, enhancing traceability and trust.

Comparison of monitoring solutions

| Monitoring solution | Key features | Benefits to you |

|---|---|---|

| Data loggers | Record temperature and humidity; manual data retrieval | Affordable, reliable compliance documentation but not real‑time |

| IoT sensors | Real‑time temperature and humidity tracking via wireless networks | Immediate alerts, predictive maintenance; higher cost and network dependence |

| RFID tags | Automated contactless temperature reading | Streamlined inventory management; requires readers and infrastructure |

| GPS trackers | Combine location with temperature data | Visibility during transit, route optimization; battery/power required |

| BLE sensors | Short‑range wireless monitoring | Low power, mobile integration; limited range |

| Smart reefers | Self‑regulating refrigerated containers | Reliable long‑distance transport; high energy cost |

Practical tips and suggestions

-

Adopt a layered approach. Combine data loggers for compliance and IoT sensors for real‑time alerts. This ensures both historical documentation and proactive intervention.

-

Invest in cloud platforms. Centralized dashboards simplify monitoring across multiple sites and enable predictive analytics.

-

Use GPS tracking for high‑value shipments. Real‑time location and temperature data help you react quickly to route deviations.

Actual case: Maersk’s remote container management system collects temperature data during ocean transport and shares it with shippers, allowing them to start quality release procedures before the cargo arrivesmaersk.com. This reduces time‑to‑market and prevents stock shortages.

How Do Advanced Packaging Solutions Protect Temperature‑Sensitive Drugs?

Direct Answer: using phase‑change materials and smart insulation

Packaging is not just a box — it’s a thermal device designed to maintain narrow temperature ranges. Advanced insulated shippers, vacuum insulation panels and phase‑change materials (PCMs) keep products stable for hours or days. PCMs store and release heat during phase transitions, absorbing excess heat during melting and releasing it during freezingtempaidcoldchain.com. This property makes them ideal for controlling temperature without active refrigerationtempaidcoldchain.com.

Background and context

Conventional gel packs have been the workhorses of cold chain packaging, but they have limitations in precision and duration. PCMs deliver more consistent temperatures, longer cooling durations and reusabilitytempaidcoldchain.com. Packaging vendors offer various PCM formats (bottles, blankets, pouches and microcapsules) to suit different products and shipping durationstempaidcoldchain.com. Sustainability also matters; biodegradable coolers and recyclable insulation reduce environmental impact.

Types of phase‑change materials

| PCM type | Description | Best use case |

|---|---|---|

| Hard bottle PCMs | Rigid containers filled with paraffin, fatty acids or salt hydratestempaidcoldchain.com | Secure handling and longer shipments |

| Blanket PCMs | Flexible sheets impregnated with PCMstempaidcoldchain.com | Custom shapes for odd‑sized packages |

| Soft pouch PCMs | Flexible pouches containing paraffin or glycolstempaidcoldchain.com | Conform to irregular items |

| Microencapsulated PCMs | Tiny PCM droplets enclosed in polymer shellstempaidcoldchain.com | Integrate into packaging materials or coatings |

| Foam PCMs | Foam impregnated with PCMstempaidcoldchain.com | Provide insulation and structural support |

| Gel pack PCMs | Gel‑like mixtures with PCMstempaidcoldchain.com | Medical and food shipments |

Advantages of PCMs over traditional gel packs

-

Precise temperature control: PCMs maintain narrow ranges and minimize excursionstempaidcoldchain.com.

-

Longer cooling duration: PCMs stay effective over extended shipping timestempaidcoldchain.com.

-

Reusability and sustainability: Many PCMs are reusable and non‑toxictempaidcoldchain.com, reducing waste and cost.

Other packaging innovations

-

Vacuum Insulation Panels (VIPs): Provide superior insulation with minimal thickness; used in high‑value shipments.

-

Active containers: Powered containers with refrigeration units, heaters and backup batteries maintain controlled environments; often used for cell and gene therapies.

-

Smart sensors integrated into packaging: Many modern shippers embed RFID tags or BLE sensors directly into the packaging to provide continuous tracking.

Practical recommendations

-

Select packaging based on stability profiles. High‑risk products like mRNA vaccines require active containers or PCMs with ultra‑low temperature thresholdsamericanbiotechsupply.com.

-

Validate packaging solutions. Perform pre‑shipment qualification, including temperature mapping, to ensure boxes maintain required ranges across expected ambient conditions.

-

Consider sustainability. Use recyclable insulation and reusable PCMs to reduce environmental impactmaersk.com.

Actual case: TempAid’s SteadyPac PCMs maintain precise temperatures and can be reused, offering longer cooling duration and eco‑friendliness compared with traditional gel packstempaidcoldchain.com.

What Are the Regulatory Requirements for Pharmaceutical Cold Chains?

Direct Answer: following GDP, GMP and national standards

Regulatory authorities insist on validated processes, documented temperature control and qualified equipment across the cold chain. In the U.S., Good Distribution Practice (GDP) and Good Manufacturing Practice (GMP) guidelines require continuous monitoring, traceable documentation and trained personnel. European regulators enforce Annex 11 data integrity rules for electronic systems. The U.S. FDA’s Vaccine Storage & Handling Toolkit and NSF/ANSI 456 standards specify storage temperatures and equipment performanceamericanbiotechsupply.com. Vaccines must remain between 2 °C and 8 °C unless specified otherwiseamericanbiotechsupply.com, and digital data loggers with buffered probes are recommended for monitoringamericanbiotechsupply.com.

Background and context

Regulations evolved from the experience of large‑scale vaccine distribution, particularly during the COVID‑19 pandemic. Authorities now expect real‑time monitoring and robust contingency plans. CDMOs and logistics providers must integrate IoT monitoring, validated packaging and supply chain documentation to meet audits. Failure to comply can result in product recalls, financial penalties and reputational damage.

Compliance checklist

-

Accurate temperature maintenance: Keep products within required ranges (2 °C–8 °C for most vaccines, −20 °C for freezing, −70 °C or lower for ultra‑cold).

-

Continuous monitoring: Use automated data loggers and real‑time systems to track temperatures 24/7.

-

Validated infrastructure: Ensure refrigerators, freezers, containers and sensors are calibrated and validated.

-

Detailed record‑keeping: Maintain logs, calibration records and training documentation for audits.

-

Contingency planning: Develop protocols for power loss and temperature excursions.

-

Staff training: Train personnel on cold chain handling and emergency procedures.

Handling vaccines and biologics

Pfizer‑BioNTech’s 2024‑2025 formulation must be stored at −90 °C to −60 °C until expiration, then refrigerated at 2 °C–8 °C for up to 10 weeks after thawingamericanbiotechsupply.com. Moderna’s vaccine follows similar guidelinesamericanbiotechsupply.com. Always consult manufacturer instructions and CDC guidance for vaccine handling, and never refreeze thawed vaccines.americanbiotechsupply.com

Actual case: Digital data loggers with buffered probes are now the standard for vaccine storage in the U.S., ensuring accurate measurement of minimum and maximum temperaturesamericanbiotechsupply.com.

How Can You Mitigate Risks and Handle Temperature Excursions?

Direct Answer: proactive monitoring, response and documentation

Preventing and responding to temperature excursions requires continuous monitoring, quick intervention and thorough documentation. Real‑time alerts allow logistics teams to take action immediately when temperatures deviatemaersk.com. Intervention strategies include adjusting refrigeration units, switching to backup power, rerouting shipments or re‑icing packagesmaersk.com. After any excursion, investigate root causes, document corrective actions and review procedures to prevent recurrence.

Background and context

Despite the best efforts, variables such as delayed flights, broken equipment or human error can cause temperature excursions. Studies show that even brief exposures outside the 2 °C–8 °C range can invalidate an entire vaccine batch. Real‑time visibility and intervention strategies protect product integrity and reduce financial lossesmaersk.com.

Risk mitigation techniques

-

Real‑time alerts and notifications: Use IoT sensors and GPS trackers that automatically notify stakeholders of deviationsmaersk.com.

-

Automated corrective actions: Systems can adjust refrigeration settings, activate backup units or reroute shipments automatically when excursions occurmaersk.com.

-

Contingency planning: Establish SOPs for repackaging, re‑icing, transferring to alternate storage and documenting actionsmaersk.com.

-

Root cause analysis: After every excursion, investigate the cause (e.g., equipment failure, power outage, human error) and update SOPs.

-

Training and drills: Regularly train staff on emergency response procedures and conduct simulations to ensure readinessmaersk.com.

Real‑world example

Maersk’s integrator strategy integrates remote temperature data from reefers with dedicated control‑tower teams who can intervene immediatelymaersk.com. This approach has helped customers cut product losses, reduce time‑to‑market and improve inventory managementmaersk.com.

What Trends Will Shape Pharmaceutical Cold Chain Logistics in 2025 and Beyond?

Direct Answer: AI, IoT, blockchain and sustainability

The future of cold chain logistics is digital, predictive and green. Three innovation trends — real‑time visibility via IoT, predictive intelligence via AI and trustworthy traceability via blockchain — are reshaping cold chain logisticsmaersk.com. Sustainability is a fourth pillar driving investment in solar‑powered cooling, smart insulation and eco‑friendly packagingmaersk.com.

Trend overview

IoT and real‑time precision

IoT systems provide live updates on climatic conditions and locationmaersk.com. At Gulf ports like Jebel Ali, RFID and Bluetooth tags reduce temperature fluctuations and support expanded cold storage capacitymaersk.com. Remote control capabilities allow operators to adjust temperature settings from anywheremaersk.com.

AI and predictive logistics

Artificial intelligence transforms raw data from sensors into actionable insights. AI models forecast demand spikes (e.g., during Ramadan) and optimize routes to reduce fuel consumption and cooling lossesmaersk.com. AI‑driven inventory management prevents stock‑outs and supports dynamic restockingmaersk.com. Healthcare supply chain leaders like Mayo Clinic and Cleveland Clinic use robotics and predictive analytics to reduce wasteicdevents.com.

Blockchain and traceability

Blockchain creates tamper‑proof records of shipment events, synchronizing customs data and cutting clearance timesmaersk.com. Automated data logging integrated with blockchain ensures every step of the cold chain is recordedmaersk.com, simplifying audits and enhancing regulatory compliance.

Greener cold chains and sustainability

Sustainability initiatives, such as solar‑powered cooling units, smart insulation and compostable packaging, lower costs and carbon emissionsmaersk.com. Gulf countries align these measures with national visions like Saudi Arabia’s Vision 2030 and the UAE’s Net Zero 2050 strategiesmaersk.com. Organizations increasingly report environmental and social performance across supply chainsicdevents.com, driving adoption of circular economy initiatives and green logistics.

Resilience and diversification

Diversifying suppliers and regional distribution centers builds resilience against geopolitical instability and capacity constraintsicdevents.com. Cloud‑based platforms provide real‑time visibility and collaborative governance, enabling suppliers, distributors and providers to synchronize inventories and reduce misalignmenticdevents.com. Healthcare companies invest in multi‑source procurement and decentralization to maintain continuityicdevents.com.

Key advancements at a glance

| Trend | What it means | Why it matters to you |

|---|---|---|

| IoT visibility | Real‑time updates on temperature and locationmaersk.com | Enables proactive intervention, reduces losses |

| AI and predictive analytics | Forecasts demand, optimizes routes, automates inventorymaersk.com | Prevents stock‑outs, minimizes waste and fuel use |

| Blockchain | Creates tamper‑proof records and synchronizes datamaersk.com | Enhances trust, speeds customs clearance and simplifies audits |

| Sustainability | Solar cooling, eco‑packaging, ESG reportingmaersk.comicdevents.com | Reduces environmental impact and meets regulatory expectations |

| Resilience & diversification | Multi‑source procurement, decentralizationicdevents.com | Ensures continuity amid disruptions |

Practical implications for your organization

-

Invest in digital infrastructure. Combine IoT sensors with AI platforms to gain predictive insights and optimize operations.

-

Adopt green practices. Use renewable energy in warehouses, implement recyclable packaging and track Scope 3 emissions.

-

Prepare for new regulations. Countries will increasingly mandate traceability and environmental reporting; start integrating blockchain and ESG frameworks.

Actual case: In the Middle East, distributors are trialling compostable packaging and solar‑powered cooling units to meet new sustainability regulationsmaersk.com. This reduces energy costs while aligning with national net‑zero strategiesmaersk.com.

Frequently Asked Questions

What is cold chain management in pharmaceuticals?

Cold chain management refers to maintaining temperature‑controlled environments for drugs from manufacturing to administration. It includes storage, transportation, packaging and monitoring to ensure product safety and efficacypharmasource.global.

Why must vaccines be stored between 2 °C and 8 °C?

Most vaccines are biologics that degrade outside this range. Storing them at 2 °C–8 °C preserves potency and reduces wasteamericanbiotechsupply.com. Some products, like mRNA vaccines, require ultra‑cold conditionsamericanbiotechsupply.com.

How do IoT sensors improve cold chain reliability?

IoT sensors provide real‑time temperature and humidity data, triggering alerts when conditions deviate. They allow for immediate corrective actions and predictive maintenance, reducing the risk of excursions.

What is a phase‑change material (PCM)?

PCMs are substances that absorb or release heat when they change state (solid ↔ liquid), maintaining stable temperatures inside packagingtempaidcoldchain.com. They offer precise control, longer cooling duration and reusabilitytempaidcoldchain.com.

Which regulations govern pharmaceutical cold chains?

Good Distribution Practice (GDP), Good Manufacturing Practice (GMP), EU Annex 11, and NSF/ANSI 456 standards require continuous temperature monitoring, validated equipment and comprehensive documentation.americanbiotechsupply.com provides specific vaccine storage guidelines.

How can companies reduce environmental impact?

Adopt sustainable packaging (recyclable insulation and PCMs), use renewable energy for storage facilities and implement circular logistics. Many organizations are investing in solar‑powered cooling and compostable packagingmaersk.com.

Summary and Recommendations

Effective cold chain management safeguards the efficacy and safety of pharmaceuticals by maintaining products within strict temperature ranges. In 2025, the cold chain market exceeds US $6.6 billionpharmasource.global, reflecting the surge of biologics and personalized therapies that demand meticulous temperature control. Technologies like IoT sensors, RFID tags, GPS trackers and cloud platforms deliver real‑time visibility, while advanced packaging solutions such as PCMs ensure thermal stability over long distances. Regulatory frameworks (GDP, GMP, FDA and WHO guidelines) mandate continuous monitoring, documentation and contingency planning. Future trends — AI‑driven logistics, blockchain traceability and sustainability initiatives — will make cold chains smarter, greener and more resilient.

Actionable Next Steps

-

Assess your current cold chain. Conduct a gap analysis of monitoring technologies, packaging solutions, documentation and staff training.

-

Upgrade monitoring systems. Implement IoT sensors and cloud platforms for real‑time visibility and predictive analytics.

-

Validate and diversify packaging. Use PCMs or active containers for ultra‑sensitive products; verify insulation performance across ambient conditions.

-

Strengthen compliance. Review GDP/GMP guidelines, calibrate equipment, maintain temperature logs and train staff regularly.

-

Plan for sustainability. Incorporate renewable energy in storage facilities, switch to recyclable packaging and track carbon footprint.

-

Embrace innovation. Pilot AI and blockchain solutions to improve forecast accuracy, ensure traceability and reduce manual workload.

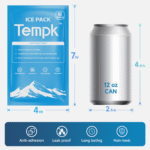

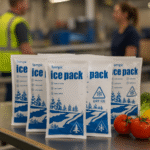

About Tempk

Tempk is a pioneer in cold chain technology, helping pharmaceutical, biotech and healthcare organizations protect sensitive products. We specialize in IoT monitoring devices, phase‑change packaging and digital platforms that deliver continuous visibility and compliance. With decades of experience, our team understands regulatory requirements and can tailor solutions to your specific needs. We invest heavily in research, ensuring our products reflect the latest scientific findings and sustainability standards.

Ready to optimize your cold chain? Contact Tempk to schedule a free consultation and discover how our solutions can protect your products, reduce waste and enhance patient safety.