How to Choose the Best Commercial Ice Box Exporter in 2026?

Updated: January 11, 2026

Choosing a commercial ice box exporter is more than comparing prices. The right partner influences how long your products stay cold, how durable the cooler is and whether you comply with evolving regulations. In 2026 the cold-chain market is expanding rapidly; global cooler box revenues were around USD 2.217 billion in 2024 and are projected to reach USD 3.138 billion by 2032. Simultaneously, cold-chain infrastructure investments mean there are roughly 5 million refrigerated road vehicles and 1.2 million refrigerated containers worldwide. This guide explains how to choose, customize and export commercial ice boxes that meet modern demands.

This guide will help you understand:

- What defines a reliable commercial ice box exporter? – Learn how manufacturing processes affect durability and ice retention.

- Which materials and insulation technologies are best in 2026? – Compare polyethylene, foam and vacuum insulation panels (VIPs) to keep ice frozen for days.

- How global regulations and sustainability trends shape exports – Discover how the EU Packaging & Packaging Waste Regulation (PPWR) and other policies drive reusable designs.

- How to evaluate suppliers and partnerships – Use scorecards and checklists to ensure quality control, documentation and scalable production.

- What innovations are coming in 2026? – Explore automation, micro-fulfilment hubs and smart technology transforming cold-chain logistics.

What defines a reliable commercial ice box exporter?

Reliable exporters prioritise repeatable performance, structural strength and regulatory compliance rather than just volume. They produce heavy-duty insulated boxes designed for repetitive use in commercial cold-chains. When you buy at scale small inconsistencies amplify across hundreds of shipments, so you need a partner who delivers consistent insulation, strong construction and documented testing.

A dependable exporter will:

- Offer diverse manufacturing processes. Rotational molding (rotomolding) spins a hollow mould filled with polyethylene powder to produce thick walls and seamless corners. Rotomolded coolers keep ice for 7–10 days when pre-cooled and loaded properly. Injection molding injects molten plastic into two shells joined with foam; these units are lighter but usually retain ice for 1–3 days. Blow molding inflates a plastic tube to form a hollow body; it is cost-efficient but results in less uniform wall thickness.

- Provide documented material performance. High-quality exporters will test their coolers using standard protocols and share reports on insulation performance, structural strength and hold time. Look for suppliers that meet food-contact safety, bear-resistant certification and maintain ISO-compliant factories.

- Include quality control and customisation. Capable OEMs design moulds, select appropriate materials, embed logos and customise colours or inserts. They should also sign NDAs to protect proprietary designs.

- Maintain strong supply chains and support. Reliable exporters monitor global tariffs and supply-chain disruptions. For example, research shows U.S. tariffs on insulation materials and compressors in early 2025 slightly reduced forecasts for the ice box market. An exporter with diversified sourcing can mitigate such disruptions.

Structural strength and repeatability: Industrial vs consumer coolers

Industrial ice boxes are engineered for high rotation, rough handling and documented performance, unlike consumer coolers that emphasise convenience. Repeatability reduces claims and protects your brand.

Practical tips for choosing an exporter

- Standardise sizes: Selecting two or three box sizes simplifies operations and training, especially if you ship weekly.

- Verify moulding capabilities: Ask for sample coolers produced via different methods, test their hold-time and examine seam strength.

- Check service and replacement: Exporters should offer clear warranties and replacement parts to minimise downtime.

- Visit facilities or request virtual tours to verify quality control and worker safety.

Case example: A food delivery start-up in California switched from a low-quality supplier to a rotomolded ice box OEM. Hold time improved from 48 hours to 8 days, reducing spoiled deliveries by 30% while lowering the per-shipment cost due to reusability.

How do manufacturing methods and materials influence ice box performance?

Manufacturing processes directly impact durability, weight and ice retention. When evaluating exporters, understand how each technique and material affects performance.

Rotomolding vs injection vs blow molding

- Rotomolded coolers: The mould spins slowly while heating to coat the polyethylene powder evenly. The resulting shell has seamless, thick walls and reinforced corners. Rotomolded boxes offer the highest ice retention (7–10 days) and are ideal for extended trips, vaccine transport and premium outdoor use.

- Injection-molded coolers: Molten plastic is injected into two shells then joined with foam. They are lighter and cheaper, but seams can be weak points and ice retention is typically 1–3 days. These units suit promotional giveaways or short trips.

- Blow-molded coolers: A molten plastic tube is inflated inside a mould. This fast and cost-efficient method is used for simple shapes but yields less uniform walls. Insulation is added separately; performance depends heavily on foam quality.

Material choices: Polyethylene, foam and vacuum insulation panels

- Polyethylene shells with polyurethane foam remain the industry standard for durability and cost efficiency. Polyethylene resists UV radiation and impact, while polyurethane foam provides thermal insulation.

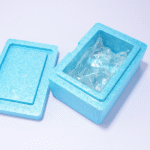

- Expanded polypropylene (EPP) offers lightweight rigidity and better shock absorption, making it popular for high-rotation industrial boxes.

- Vacuum insulation panels (VIPs) deliver the best thermal performance—some boxes maintain temperature for over 120 hours (5 days) when using VIPs. VIPs drastically reduce dry ice consumption and are ideal for pharmaceuticals or high-value cargo, but they are more expensive and require careful handling to avoid punctures.

- Phase-change materials (PCMs) complement VIPs by holding the desired temperature range; they are essential for vaccines needing 2–8 °C or other specific ranges.

When exporting, choose materials that balance cost, durability and regulatory requirements. For example, the EU’s PPWR bans certain single-use plastics from 1 January 2030 and introduces reuse requirements from August 2026. Exporters serving the EU market must use reusable materials and incorporate recycled content.

Practical tips for material and insulation selection

- Match material to your use case: For rugged outdoor markets or fishing exports, rotomolded polyethylene is ideal. For lightweight deliveries or promotional campaigns, injection-molded polypropylene may suffice.

- Plan for extreme conditions: If exporting to equatorial regions or serving pharmaceutical clients, invest in VIP-based coolers and PCMs to maintain temperatures for extended periods.

- Test under real conditions: Before committing to a shipment, test coolers with your intended payload and coolant to ensure hold time. Use data loggers to capture temperature profiles.

Real-world example: A vaccine distributor shipping to remote Pacific islands used VIP coolers with PCMs. The packages maintained 2–8 °C for 120 hours and saved 40% on dry ice costs.

How do regulations and sustainability trends affect ice box exports?

Global policies and consumer preferences are pushing exporters toward reusable, recyclable and energy-efficient coolers. Regulations influence materials, labeling and documentation. Here’s what you need to know:

EU Packaging & Packaging Waste Regulation (PPWR)

The EU’s PPWR bans certain single-use plastic packaging from 1 January 2030 and introduces mandatory reuse systems from 12 August 2026. Manufacturers must design durable, recyclable or reusable coolers and incorporate recycled materials.

Exporters targeting the EU should:

- Design for reuse: Use rotomolded or EPP structures and ensure that components can be disassembled for recycling.

- Include recycled content: Work with suppliers that offer recycled resin blends.

- Provide documentation: Prepare declarations of conformity and compliance test reports for the recycled content and material safety.

Tariff and trade considerations

Trade tensions and tariffs affect the cost of insulation materials and compressors. For example, high U.S. tariffs on imported insulation materials in early 2025 slightly reduced projected growth for the ice box market. Exporters should diversify their supply chain to mitigate risk and monitor trade agreements between origin and destination countries.

Sustainability and consumer demand

Consumers increasingly prioritise durable, reusable cooler boxes. Reusable cooler boxes represented 73% of the market value in 2024, reflecting a shift away from disposable products. Brands that highlight sustainability and durable construction build loyalty and command price premiums.

The global cold-chain industry aims to reduce food waste and carbon emissions. Inadequate cold-chain systems contribute to nearly half of global food loss, with an estimated 4.4 gigatons of CO₂ emissions. Moreover, insufficient medical cold chains cause 1.5 million vaccine-preventable deaths annually. Stronger cold-chain infrastructure not only reduces waste but also improves public health outcomes.

Practical actions to stay compliant and sustainable

- Audit your supply chain: Ensure that raw materials and production processes comply with destination regulations and are free from banned chemicals.

- Invest in reusable designs: Prioritise durable materials and modular parts for easy repairs. Communicate environmental benefits clearly to customers.

- Monitor policy changes: Keep abreast of new regional regulations (e.g., PPWR, Extended Producer Responsibility laws) and adapt your product line accordingly.

- Educate buyers: Provide instructions for proper use, cleaning and recycling to maximise the life cycle of each unit and reduce waste.

Case example: A European grocery chain adopted reusable coolers with recycled polyethylene to comply with upcoming PPWR requirements. The switch reduced packaging waste by 70% and improved brand perception among eco-conscious consumers.

How do you evaluate and partner with the right exporter?

Finding a trustworthy exporter involves more than verifying production capability. You need to assess financial stability, quality control, responsiveness and local expertise.

Key criteria to evaluate

- Export experience and market coverage. According to trade data, between June 2024 and May 2025 there were 3,652 shipments of plastic ice boxes exported worldwide by 459 exporters to 1,647 buyers, a growth rate of 147% compared to the previous year. The majority of shipments went to the United States, Vietnam and Mexico, and the top exporting countries were China (2,606 shipments), Thailand (1,679) and Mexico (651). Choose a partner with experience shipping to your target countries and familiarity with customs requirements.

- Compliance & certifications. Check whether the exporter has food-contact certificates, bear-resistant approvals, Sedex or BSCI audits and adherence to Good Manufacturing Practices.

- Thermal testing and documentation. Ask for hold-time test reports under different ambient temperatures (e.g., 30 °C, 40 °C) and for different durations (48 h, 120 h).

- Scalability and lead time. Ensure the exporter can handle your volume with consistent quality. Ask about production capacity, lead times and ability to ramp up for seasonal demand.

- After-sales support. Evaluate warranty terms, response times and spare part availability. Reliable partners provide training on packing, coolant selection and cleaning.

Building a successful partnership

- Communicate clearly: Provide detailed requirements including target hold time, capacity, branding, compliance needs and distribution plan.

- Request prototypes: Before placing large orders, request prototypes and run internal tests for performance and durability.

- Use a scorecard: Rate potential exporters across criteria such as manufacturing capability, quality control, experience, price, sustainability and responsiveness. Weighted scoring helps make an informed decision.

- Negotiate long-term contracts: Secure favorable pricing and ensure consistent supply by committing to multi-year agreements with quality clauses.

Case example: A Vietnamese seafood exporter used trade data to identify top producers in China and Thailand. After evaluating six suppliers with a scorecard, they partnered with a rotomolded cooler manufacturer and co-developed a lightweight 20 L unit with VIPs. The partnership doubled ice retention and opened new markets in the Middle East.

2026 trends and innovations shaping commercial ice box exporters

The cold-chain landscape is evolving rapidly. Keeping your product line competitive requires understanding the technological and market trends that will shape 2026 and beyond.

Automation and smart logistics

Cold-storage facilities are adopting advanced automation to improve efficiency and address labour shortages. Autonomous mobile robots (AMRs), automated storage and retrieval systems and AI-driven inventory management handle picking and packing in sub-zero environments. Automation also extends to the manufacturing of coolers; mould production, foaming processes and integration of smart sensors are becoming more precise.

Micro-fulfilment and urban logistics

The e-commerce boom is changing where cold-storage facilities are built. Retailers are creating small, strategically located hubs to shorten last-mile delivery. These micro-fulfilment centres require compact, stackable coolers with ergonomic handles and modular inserts. Exporters should design boxes that fit into smaller vehicles and urban warehouses.

Infrastructure expansion

Global demand for warehouse space is skyrocketing. The U.S. will require an additional 1 billion square feet of warehouse space by 2025 and 50,000 new warehouses will be needed worldwide over the next six years. Larger facilities and palletised systems create opportunities for bigger commercial coolers and modular designs that integrate with standard pallet footprints.

Energy efficiency and sustainability

Rising energy costs and tightening regulations are pushing operators toward sustainable solutions. Facilities are installing natural refrigerants, solar power and advanced building management systems, cutting energy consumption by 20–30%. For ice boxes, this means using hydrofluorocarbon-free foam, recycled resin blends and adopting VIPs. The market is moving toward eco-friendly designs to meet regulatory requirements and consumer expectations.

Smart technology integration

The convergence of IoT, AI and predictive analytics is transforming coolers into smart devices. By 2026, expect real-time temperature monitoring, predictive maintenance alerts and dynamic routing recommendations. Predictive weather tracking helps optimise coolant use and route planning, while track-and-trace systems provide alerts if a shipment stalls. Exporters that embed sensors and partner with software providers will offer more value.

Labour and resource pressures

Labour shortages persist in cold environments. Companies are shifting to part-time or rotating shifts to reduce burnout. Meanwhile, dry ice and coolant supplies are constrained; designing boxes that maximise coolant efficiency—such as those with VIPs—helps manage limited resources.

Global cold-chain market growth

The global cold-chain industry is on a growth trajectory. MarketsandMarkets reports that the industry was valued at USD 228.3 billion in 2024 and is projected to reach USD 372 billion by 2029. Growth is driven by international trade, expanding organised retail and demand for efficient logistics. Cold-chain innovations such as AI-powered route optimisation, blockchain for enhanced traceability, solar-powered refrigeration and lightweight shipping containers with IoT sensors are becoming mainstream. Exporters must monitor these innovations to align their products with evolving logistics networks.

Case example: During a 2025 heatwave, an exporter integrated IoT sensors and predictive weather data into their coolers. When high temperatures threatened shipments, the system triggered re-routing to maintain a 2–8 °C range, saving thousands of vaccine doses.

Frequently Asked Questions

Q1: How long can a commercial rotomolded ice box keep ice frozen?

Rotomolded coolers have thick, seamless walls and injected foam insulation that maintain ice for 7–10 days when properly pre-cooled and loaded. They’re ideal for extended trips or professional use.

Q2: Are vacuum insulation panels worth the premium cost?

Yes. VIPs offer the lowest thermal conductivity (~2–4 W/m·K) and maintain cold temperatures for over 120 hours, reducing the amount of coolant needed. However, they are expensive and must be handled carefully to avoid punctures.

Q3: What size cooler should I choose for vaccine transport?

Vaccines typically require temperatures between 2 and 8 °C. Select a cooler with validated insulation and, ideally, VIPs or phase-change materials. Ensure it accommodates the number of vials with space for coolant and use a temperature logger for compliance.

Q4: Who are the major players in the cooler box market?

Major companies include Igloo Products Corp., YETI Coolers LLC, Rubbermaid Commercial Products, Coleman (Esky) and Stanley. These brands lead market share through product innovation and strong branding.

Q5: Which countries are the top exporters of plastic ice boxes?

From June 2024 to May 2025 the world exported 3,652 shipments of plastic ice boxes, with most exports destined for the United States, Vietnam and Mexico. The top exporting countries were China (2,606 shipments), Thailand (1,679) and Mexico (651).

Summary and recommendations

Key takeaways:

- Manufacturing method matters: Rotomolded coolers offer superior ice retention and durability but are heavier and cost more; injection and blow-molded options suit cost-sensitive or short-term needs.

- Material and insulation choices dictate performance: Polyethylene shells with foam provide a balance of durability and cost, while VIPs offer premium thermal performance for sensitive cargo.

- Regulations and sustainability are shaping exports: EU packaging rules enforce reusable designs and recycled content by 2026. Consumers increasingly prefer sustainable, reusable cooler boxes; reusable units accounted for 73% of market value in 2024.

- Market opportunities are expanding: Global cold-chain investment and growth in outdoor recreation are driving demand. The cooler box market is expected to reach USD 21.1 billion by 2034 at a CAGR of 9.4%.

- Export partnerships require due diligence: Evaluate exporters’ manufacturing capabilities, certifications, thermal testing and supply-chain resilience. Use scorecards to compare partners and request prototypes.

Action plan:

- Define your use case: Determine whether you need long-term ice retention, lightweight portability or a balance of both. This drives manufacturing method and material choice.

- Conduct supplier assessments: Shortlist exporters with proven experience in your target markets and evaluate them using a weighted scorecard. Examine certifications, quality control processes and sustainability commitments.

- Request prototypes and run tests: Test hold time under real conditions using temperature loggers. Adjust coolant volumes and packing methods accordingly.

- Negotiate terms and volumes: Secure favourable pricing and consistent supply by negotiating long-term contracts. Include clauses for quality assurance, defect handling and sustainability compliance.

- Plan for future trends: Integrate IoT sensors, design modular inserts for micro-fulfilment and choose VIPs or recyclable materials to meet 2026 regulations and energy-efficiency demands.

About Tempk

Tempk is a leading cold-chain packaging manufacturer specialising in reusable ice boxes, gel packs and insulated bags. Our team combines materials science expertise with modern manufacturing techniques to deliver durable, high-performance coolers for food, pharmaceutical and industrial customers. We prioritise eco-friendly materials and support partners with R&D, customisation and compliance guidance.

Ready to cool smarter? Contact Tempk’s experts today for a consultation on designing a commercial ice box solution that meets your needs and sustainability goals.