Dry Ice Cubes vs Dry Ice Pack: Which Keeps Cold?

If you’re choosing between dry ice cubes and a dry ice pack for time‑critical shipping, here’s the short answer: pick cubes for fast pull‑down and deep freeze, pick packs for cleaner handling and controlled release. In cold chain work, those choices decide hold time, safety, cost, and compliance. This guide shows you exactly when to use each, with 2025‑ready workflows you can apply today.

-

When to use dry ice cubes vs a dry ice pack for vaccines, biologics, and frozen foods

-

How to size dry ice for 24–72 hour lanes with real‑world assumptions

-

Pack‑out designs that balance hold time, cost, and condensation risk

-

Safety and compliance for CO₂ venting, labeling, and documentation

-

2025 trends in dry ice production, greener options, and reusable carriers

How do dry ice cubes and a dry ice pack differ for cold‑chain shipping?

Direct answer

Dry ice cubes deliver rapid cooling and long hold when massed; a dry ice pack delivers cleaner handling, lower dust, and steadier release. Use cubes for fast pull‑down below −40 °C; use packs when you need tidy, repeatable pack‑outs and easier SOP training. Expect higher surface contact (and frost risk) with cubes; expect gentler ramp rates with a dry ice pack.

Why this matters

In practice, you care about a shipment’s temperature curve, not just “cold.” Dry ice cubes expose more surface area and drive quick temperature drops—great for rapid stabilization, but they can create cold spots. A dry ice pack is pre‑formed CO₂ ice inside a sleeve or film that sublimates in a more uniform way. For diagnostic kits or last‑mile deliveries where techs rotate quickly, packs standardize the process and reduce handling errors. Both options must vent CO₂; neither is “sealed.” For complex lanes, labs often combine them: dry ice cubes for initial pull‑down, dry ice pack bricks for stability during transit.

How much dry ice pack or cubes do you need per shipment?

Details you can use

Estimate by balancing heat gain against sublimation. Typical field assumptions for insulated shippers: ambient 20–25 °C; 24‑hour heat ingress of ~6–12 W for a 12–18 L shipper; dry ice sublimation rates around 2.5–4.5 kg per 24 h depending on insulation and venting. For short lanes and smaller payloads, a dry ice pack set (pre‑formed bricks) keeps handling simple. For longer lanes, add dry ice cubes mass to push hold time past 48–72 h.

| Decision Factor | Dry Ice Cubes | Dry Ice Pack | What it means for you |

|---|---|---|---|

| Cooling speed | Fast pull‑down (high surface area) | Moderate, more even | Faster stabilization vs smoother curve |

| Dust/handling | Higher dust; scoop or bag required | Low dust; tidy bricks | Easier training and SOP adherence |

| Pack‑out repeatability | Variable if hand‑filled | High—brick counts | Fewer packing errors |

| Hold time per mass | Strong when massed | Strong, more predictable | Both work; packs reduce variability |

| Cold spots risk | Higher if touching vials | Lower with spacing | Use trays/dividers with cubes |

Practical tips and suggestions

-

Biologics in vials: Use a divider or tray. Keep dry ice cubes from direct vial contact to avoid brittle fractures.

-

Kits and e‑commerce: Standardize on a dry ice pack count (e.g., four 500 g bricks) to cut training time and returns.

-

Weekend risk: Add a 25–30% buffer mass if a lane might slip from 48 to 72 h due to handoff delays.

Real‑world case: A reference lab switched from loose dry ice cubes to a 4‑brick dry ice pack SOP for 36‑hour regional lanes. Breakage dropped, pack errors fell 60%, and the lab extended safe time by ~8–10 hours thanks to more consistent sublimation and better venting.

When should you choose a dry ice pack vs dry ice cubes?

Direct answer

Choose dry ice cubes for deep‑freeze pull‑down, international air cargo, and heavy payloads. Choose a dry ice pack for clinic returns, small kits, and repeatable last‑mile routes. If the route is long and uncertain, combine both: cube bed on the bottom, dry ice pack bricks along the payload walls.

Scenario mapping

-

Frozen seafood export: Build mass with dry ice cubes; add a top layer of dry ice pack bricks to smooth the curve and reduce cold‑spot complaints.

-

Genetic testing kits: Use a fixed count of dry ice pack bricks. Include a clear SOP image in the carton.

-

Temperature‑sensitive reagents: Start with dry ice cubes for pull‑down, then switch to packs in a mid‑mile hub if you re‑ice.

Safety and compliance for dry ice pack and dry ice cubes

Essential points

Dry ice (solid CO₂) vents gas as it warms. Both dry ice pack and dry ice cubes need breathable space; never tape a shipper shut without vent paths. On air shipments, dry ice is a regulated dangerous good (UN 1845). Packages require correct net mass declaration and hazard marking. In workspaces, manage CO₂ build‑up with ventilation and alarms per occupational safety practices.

| Topic | Dry Ice Cubes | Dry Ice Pack | Your takeaway |

|---|---|---|---|

| Venting | Essential; avoid sealed liners | Essential; film must vent | Always include vent channels |

| Labeling | Declare net mass of dry ice | Same requirement | Document the exact kilograms |

| Handling | Scoops, gloves, dust mask | Gloves; low dust | Packs reduce housekeeping load |

| Training | More variable | Easier to standardize | Faster onboarding with packs |

Pack‑out that avoids condensation and cold shock

What to do

Use a liner bag that’s not airtight, add a paper spacer or corrugate between the payload and dry ice cubes, and position dry ice pack bricks along walls to even the temperature field. For glass vials, target a gentle ramp: cubes at the base, bricks on the sides, payload tray above a mesh or perforated board.

Micro‑trial tip: Before you roll out site‑wide, run two 24‑hour dummy shipments—one all cubes, one mixed with a dry ice pack. Compare probe curves and returns data. Pick the design with the fewest out‑of‑spec minutes, not just the longest hold time.

How do you size dry ice for 24–72 hours without guesswork?

Direct answer

Start from heat load, not from “how many bricks.” Estimate watts of heat leak from the container, convert to kJ over time, divide by dry ice latent plus sensible load. Then round up and add a weekend buffer. This works for both dry ice cubes and a dry ice pack design.

A quick, practical estimator (rule‑of‑thumb)

-

Find shipper loss: Good EPS shipper: ~8–12 W; premium VIP: ~2–4 W.

-

Pick duration: 24, 48, or 72 hours.

-

Compute energy:

Watts × hours × 3.6 = kJ. -

Dry ice capacity: ~570–650 kJ per kg usable in real pack‑outs.

-

Mass needed:

kJ ÷ 600 ≈ kilograms. Add 20–30% safety stock.

Example

A 10 W shipper for 48 h needs: 10 × 48 × 3.6 = 1728 kJ.1728 ÷ 600 ≈ 2.88 kg, plus 30% buffer ≈ 3.7 kg of dry ice. Use 2 kg dry ice cubes under the tray and four 500 g dry ice pack bricks around the sides.

Sizing table you can adapt

| Shipper Class | Heat Leak (W) | 48 h Mass (kg) | What to load |

|---|---|---|---|

| EPS good | 10–12 | 3.5–4.5 | 2–3 kg dry ice cubes + 2 kg dry ice pack |

| PUR / mid | 6–8 | 2.5–3.5 | 1.5–2 kg cubes + 1–1.5 kg packs |

| VIP premium | 2–4 | 1–2 | 0.5–1 kg cubes + 0.5–1 kg packs |

Quick safety margins that work

-

Uncertain pickup time: Add 0.5–1 kg.

-

Hot lane (30 °C+): Add 25%.

-

Large payload >8 kg: Prefer more dry ice cubes mass to control pull‑down.

Cost, waste, and sustainability: which is better?

Direct answer

Dry ice cubes are often cheaper per kilogram, especially when delivered in bulk. A dry ice pack can reduce hidden costs: faster training, less dust cleanup, and fewer damaged payloads. If you measure cost per successful delivery (not per kilogram), packs often win on short and mid routes.

Reducing CO₂ footprint while staying cold

-

Right‑size the shipper first. Lower heat leak means less CO₂ needed.

-

Use mixed loads. A cube base plus dry ice pack bricks keeps curves tight with less total mass.

-

Re‑ice at a hub. Split long routes into 2×36 h with a documented re‑icing SOP.

-

Source renewable CO₂ when available. Some suppliers now recover CO₂ from biogenic streams.

Customer story: A seafood exporter cut total dry ice mass by ~22% after moving to a cube‑plus‑pack design in VIP shippers, while complaint rates about “frozen outer fillets” dropped to near zero.

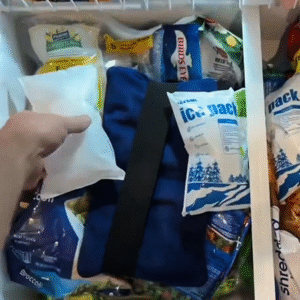

Step‑by‑step: pack with a dry ice pack (repeatable SOP)

-

Stage the payload in a tray with dividers; pre‑cool components.

-

Place two dry ice pack bricks on opposite walls; leave vents unobstructed.

-

Add a cube bed (if needed) under a perforated tray for faster pull‑down.

-

Insert the payload; add remaining dry ice pack bricks to fill wall channels.

-

Close the liner loosely so CO₂ can vent; never hermetically seal.

-

Record net dry ice mass (kg) on docs and carton.

-

Apply hazard mark and arrows; include the SOP diagram on the inner flap.

2025 trends in dry ice cubes and dry ice pack solutions

Trend overview

In 2025, more shippers are switching to hybrid pack‑outs—dry ice cubes for early stage pull‑down, dry ice pack bricks for steady release and simpler training. Re‑icing programs at mid‑mile hubs are rising, enabled by IoT probes and lane analytics. Suppliers are expanding biogenic CO₂ recovery and offering standardized brick sizes to match common cavity designs.

What’s new at a glance

-

Standardized brick formats: 250 g, 500 g, and 1 kg dry ice pack sizes align with common 12–18 L shippers.

-

Cleaner handling: Lower dust films and glove‑friendly textures reduce GMP housekeeping load.

-

Thermal modeling tools: Easier calculators turn hours and ambient into a dry ice mass recommendation for both dry ice cubes and packs.

Market insight

Healthcare and seafood lanes still dominate dry ice demand, but direct‑to‑consumer frozen products continue to grow. The winning pack‑outs emphasize repeatability, simple SOPs, and fewer cold‑spot incidents. As premium insulation spreads, total dry ice mass per shipment drops, but consistency and documentation standards rise.

Frequently Asked Questions

Q1: How long will a dry ice pack keep my shipment cold?

Most mid‑size shippers with four 500 g dry ice pack bricks hold 24–48 h at room temperature. Add bricks or dry ice cubes to reach 72 h. Venting and insulation quality decide the final number.

Q2: Are dry ice cubes colder than a dry ice pack?

Both are −78.5 °C. Cubes feel “colder” because they expose more surface area and speed pull‑down. A dry ice pack spreads cooling more evenly.

Q3: Can I use dry ice pack bricks on passenger aircraft?

Yes, dry ice (UN 1845) is allowed with limits and markings. Declare net mass and follow airline rules. Venting and labeling are mandatory.

Q4: Will dry ice damage vials or packaging?

Direct contact can cause brittle fracture or cracking. Add a tray or corrugate spacer. Place dry ice pack bricks along walls to avoid cold spots.

Q5: How do I prevent CO₂ buildup in vehicles or small rooms?

Ventilate. Keep shippers in airy spaces, use CO₂ monitors where required, and train staff. Both dry ice cubes and dry ice pack designs release gas as they warm.

Q6: What’s the best layout for mixed payloads?

Try a cube bed below a perforated tray with dry ice pack bricks on the sides. This balances pull‑down and uniformity.

Q7: How do I calculate net dry ice mass for paperwork?

Weigh the shipper empty, weigh again loaded, subtract payload and packaging. Record the dry ice cubes and dry ice pack totals in kilograms.

Interactive worksheet: 5‑minute dry ice sizing check

Your inputs

-

Shipper type (EPS / PUR / VIP)

-

Target hours (24/48/72)

-

Ambient profile (mild / hot)

-

Payload mass (kg)

Quick rules

-

EPS + 48 h + mild: start at ~3 kg total; split between dry ice cubes and dry ice pack.

-

VIP + 72 h + hot: start at ~2.5–3 kg total; favor a mixed layout with extra side bricks.

-

Add 25–30% if any handoff might slip a day.

Pass/fail checklist

-

Venting path visible

-

Net dry ice mass recorded

-

No direct cube‑to‑vial contact

-

Brick count matches SOP image

Summary and recommendations

Key takeaways

-

Dry ice cubes give fast pull‑down and long hold when massed.

-

A dry ice pack offers cleaner handling and repeatable brick counts.

-

Hybrid layouts often win: cube bed + side packs.

-

Right‑size by heat load, then add a 20–30% buffer.

-

Document net mass and venting; train for consistency.

Next steps (CTA)

-

Choose your primary format per lane: cubes for deep freeze, packs for repeatability.

-

Build a 24–72 h sizing table for your top three shippers.

-

Run two micro‑trials this week and lock the best SOP.

-

Need help? Request a free pack‑out review from Tempk and get a lane‑specific calculator and SOP graphic.

About Tempk

We build reliable cold‑chain packaging that balances hold time, handling, and cost. Our team designs SOPs that cut packing errors while keeping your product in range. We offer validated shippers, dry ice pack formats, and training support. Customers report reduced re‑icing events and fewer temperature excursions after adopting our mixed dry ice cubes plus pack layouts.