Dry Ice Pack 7×13: How to Size and Ship in 2025?

If you ship frozen goods, a dry ice pack 7×13 gives deep-freeze control for 24–72 hours when right-sized and vented. You must apply UN1845 marks, declare net dry-ice weight, and follow 2025 IATA/OSHA rules to avoid delays or safety issues. This guide merges best practices, a simple sizing formula, and compliance checklists you can use today.

-

Choose when a dry ice pack 7×13 beats gel or PCM for frozen shipping.

-

Calculate pack counts with a fast formula and a one-minute tool.

-

Label and vent correctly under UN1845, IATA PI 954, and 49 CFR rules.

-

Cut risk with PPE, storage, and lane-specific packout patterns.

What is a dry ice pack 7×13, and when should you use it?

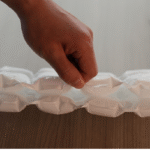

A dry ice pack 7×13 is a vented 7×13-inch pouch you fill with dry-ice pellets, delivering −78.5 °C source cooling for frozen lanes. Use it when your payload must arrive fully frozen for 24–72 hours and you can follow hazmat marking and venting rules. It nests around corners, reduces air gaps, and fits small parcel coolers efficiently.

Why it’s useful for you: The format blankets small loads without heavy overpack. It produces no meltwater, keeps cartons dry, and simplifies acceptance when you mark UN1845 and show net kilograms. If your target band is 2–8 °C, consider PCM or a hybrid to avoid over-cooling sensitive goods.

Sizing rules of thumb for dry ice pack 7×13 loads

Start with ~1–1.5 lb (0.45–0.7 kg) of dry ice per 24 h per 6–8 L of insulated volume, then scale for duration and season. Round up your final count because sublimation starts as soon as pellets are loaded. For hot routes, add 25–50% more than winter baselines.

| Packout component impact | What it is | What to check | What it means for you |

|---|---|---|---|

| Dry-ice source | Solid CO₂ at −78.5 °C | Pellet size, freshness | Predictable ultracold performance without liquid residue. |

| 7×13 bag | Vented CO₂-safe pouch | Seam integrity, vent path | Gas escapes; reduced rupture risk and easier air acceptance. |

| Insulated shipper | EPS, EPP, VIP, rigid coolers | R-value, tight pack | Lower sublimation and longer hold time for same mass. |

Practical tips and suggestions

-

Frozen food parcel: Prefreeze below −18 °C; top-blanket one dry ice pack 7×13 and place another along the warm wall.

-

Lab samples: Use secondary containment; position packs around racks, not directly on fragile vials.

-

Summer lanes: Upsize the dry ice pack 7×13 count by 25–50% and vent the lid path.

Real-world case: A dessert brand used two dry ice pack 7×13 units in a 10 L shipper for 2-day air during 32 °C ambient. Pints arrived rock-solid and cartons stayed dry because dry ice sublimates, not melts.

How many dry ice pack 7×13 units do you need for 24–72 hours?

Use a three-step calculator: estimate 24 h need from volume, scale by hours and lane factor, then convert kilograms to packs. This keeps sizing transparent and repeatable across teams. Keep packaging vented; US rules require CO₂ release.

Expanded guidance: Start with the volume-based baseline, multiply by time and a lane factor (1.0 cool, 1.25 average, 1.5 hot), then divide by your typical per-pack fill. Place one dry ice pack 7×13 at the highest heat-gain surface (usually the top) and another near the label side. Validate on real lanes with data loggers.

Micro-calculator: quick estimator for dry ice pack 7×13

| Example lane | Volume (L) | Hours | Lane factor | Result | For you |

|---|---|---|---|---|---|

| Domestic 2-day air | 10 | 48 | 1.25 | 2–3 dry ice pack 7×13 | Add one at top, one warm wall. |

| Hot-season parcel | 14 | 36 | 1.5 | 3–4 packs | Increase mass; reduce voids. |

| Overnight, VIP shipper | 8 | 24 | 1.0 | 1–2 packs | Validate; may downsize mass. |

Actual example: A diagnostics shipper cut complaints by switching to two dry ice pack 7×13 plus a vented lid; logger traces confirmed 48-hour stability.

Compliance and safety for dry ice pack 7×13 in 2025?

Do four things: vent packaging, apply the Class 9 label, mark “UN1845” with net dry-ice kilograms, and follow IATA PI 954/49 CFR 173.217. Keep a copy of the 2025 acceptance checklist in your SOPs. For worker safety, use cryo-gloves, eye protection, and good ventilation.

Why it matters to you: Vented design prevents pressure buildup, the UN1845 mark and net-kg figure speed air-carrier acceptance, and consistent labeling avoids returns. OSHA’s 8-hour CO₂ limit is 5,000 ppm; NIOSH lists IDLH at 40,000 ppm—training and monitors reduce risk in staging areas.

Labeling and documentation checklist

-

Vent it: Packaging must permit CO₂ release; never fully seal coolers.

-

Mark it: Print UN1845 and net dry-ice weight (kg) on the outer box.

-

Label it: Apply the Class 9 hazard label; place where visible after handling.

-

Document it: Show UN1845 and net kg on the air waybill when applicable.

| Labeling element | Requirement | Common slip | What it means for you |

|---|---|---|---|

| UN1845 text | On outer package | Missing net kg | Delays or refusal at acceptance. |

| Class 9 label | Per IATA/Carrier | Wrong placement | Re-work and missed uplift. |

| Vent path | “Must permit release” | Taped-shut lid | Rupture risk; non-compliant. |

Dry ice pack 7×13 vs gel and PCM—what fits your lane?

Pick a dry ice pack 7×13 for shipments that must arrive frozen; pick gel/PCM when you need 2–8 °C. Dry ice is ultracold and residue-free but requires hazmat marks; PCM targets narrow setpoints and eases air acceptance. Hybrids often win for mixed loads.

In practice: Top-blanket a dry ice pack 7×13 to protect frozen SKUs, then place +5 °C PCM panels closer to sensitive items. This limits freeze risk, simplifies compliance, and can reduce total dry-ice mass on summer lanes. Validate both winter and summer profiles.

Decision guide: choose the right refrigerant

-

Frozen-only payloads: Favor dry ice pack 7×13 only; maximize insulation before adding mass.

-

Strict 2–8 °C corridors: Prefer PCM first; add minimal dry-ice buffer if needed.

-

Mixed payloads: Use a divider; combine PCM and dry ice pack 7×13 with a clear vent path.

2025 trends shaping dry ice pack 7×13 usage

Three shifts to plan for in 2025: tighter air-acceptance discipline around UN1845 net-kg marks; wider adoption of cellular/BLE data-loggers; and sustainability pressure that drives hybrid PCMs and higher-R shippers to lower dry-ice mass. The upshot is better monitoring, fewer acceptance errors, and lower cost per lane.

Latest progress at a glance

-

Operator caps: Some airlines require declaring net dry-ice mass at booking for aircraft-level limits.

-

Connected packouts: Off-the-shelf loggers simplify continuous monitoring and audit trails.

-

Higher-R packaging: VIP and molded EPP reduce sublimation for the same dry ice pack 7×13 count.

Market insight: Cold-chain demand keeps climbing with biologics and e-grocery. Expect more validation asks, more sensor data in QMS, and more emphasis on rightsized dry ice pack 7×13 mass per route and season.

Frequently Asked Questions

How long will a dry ice pack 7×13 last?

Plan for 24–72 hours depending on insulation, ambient heat, and fill mass. Start with 1–1.5 lb per 24 h per 6–8 L and round up for hot lanes.

What labels are required when I use a dry ice pack 7×13?

Apply the Class 9 label and mark UN1845 with net dry-ice kilograms on the box; include UN1845 and net kg on the air waybill when applicable.

Is a dry ice pack 7×13 safe to handle?

Yes—use cryo-gloves and eye protection, work in ventilated areas, and never seal CO₂ in a tight container.

Can I mix a dry ice pack 7×13 with PCM panels?

Yes. Separate compartments, keep a vent path clear, and validate to protect 2–8 °C items from freezing.

Summary and recommendations

Key points: A dry ice pack 7×13 delivers ultracold, residue-free performance for frozen lanes. Vent, mark UN1845 with net-kg, and follow PI 954/49 CFR rules. Rightsize with the three-step calculator, then validate on your lanes with data loggers. Consider hybrids for mixed payloads.

Next steps: Map lanes by season and hold time. Pilot two packouts with different dry ice pack 7×13 counts. Update SOPs with 2025 label/mark steps and add the acceptance checklist. Embed the calculator on your site. CTA: Request a validated packout and documentation kit from Tempk.

About Tempk

We are a cold-chain packaging and compliance team focused on practical, validated packouts. We build calculators, SOPs, and lane-specific kits—including dry ice pack 7×13 configurations—to shorten time-to-ship. Our strengths are regulatory clarity and data-backed validation runs so you can scale confidently.