Dry Ice Pack for Meat: Ship Frozen for 72 Hours?

Updated: September 22, 2025. If you need a dry ice pack for meat, this guide shows you how to size the ice, choose the box, apply 2025 labels, and validate performance. You’ll see the 5–10 lb per 24 h planner, UN 1845 marking rules, and a simple estimator to cut guesswork and reduce spoilage claims. All recommendations are field-tested against current carrier and postal guidance.

-

How much dry ice pack for meat do you need for 24–72 hours?

-

Which shipper (EPS, PUR, VIP) keeps meat frozen longest in hot lanes?

-

What 2025 labels and documents do UN 1845 shipments require?

-

When should you use gel/PCM instead of a dry ice pack for meat?

-

How do you validate results (ISTA 7E) and prove food safety to customers?

How much dry ice pack for meat do you need for 24–72 hours?

Short answer: Use 5–10 lb of dry ice per 24 hours in a quality insulated shipper, then add a 15–25% safety buffer for heat or weekend risk. Plan 15–30 lb for 72 hours and record net dry-ice mass in kilograms on the outer label.

Why it works (plain English): Insulation slows heat sneaking into the box; dry ice absorbs that heat as it turns to gas. Each kilogram soaks up a large amount of energy, so you can predict hold time with a simple rate × days × buffer plan.

Dry ice pack for meat estimator for 48–72 hours

| Sizing Variable | Typical Range | Effect on Dry Ice | What it means for you |

|---|---|---|---|

| Transit duration | 24–72 h | Linear increase | Multiply daily rate by days |

| Insulation class | EPS → PUR → VIP | Better class = less ice | Upgrade for summer lanes |

| Ambient severity | Mild → Hot | Faster sublimation | Add 15–25% buffer |

| Payload mass | 5–25 lb | More “cold battery” | Larger payload needs proportionally less ice |

Which insulated shipper keeps a dry ice pack for meat frozen longer?

Short answer: EPS is cheapest but consumes the most ice; PUR improves hold time; VIP cuts ice mass dramatically and shrinks the box. For 72-hour lanes, step up insulation or increase ice—then verify with ISTA 7E parcel profiles.

| Shipper Type | What changes | Hold-time impact | For you |

|---|---|---|---|

| EPS (1–1.5″) | Lowest cost | Uses the most ice | Budget routes, mild weather |

| PUR (1–1.5″) | Better R-per-inch | Medium ice | Tougher builds, reuse |

| VIP (0.5–1″) | Highest R-value | Least ice | Hot lanes, smallest cube |

What 2025 rules apply to a dry ice pack for meat?

You must mark and vent correctly. On the outer box show “Dry Ice” or “Carbon dioxide, solid,” UN 1845, and the net dry-ice mass in kilograms, add the Class 9 label, keep packaging vented, and follow IATA PI 954 for air. USPS air is capped at 5 lb per mailpiece; surface allows more but must be marked “Surface Only.”

Counter checklist (what agents verify): package condition; UN 1845 name/number; net kg stated; Class 9 label; addresses; and ventilation—not airtight.

When should you choose gel/PCM over a dry ice pack for meat?

Use gel or 2–8 °C PCM when you want refrigerated arrival. For meat that must stay frozen, a dry ice pack for meat is still the simplest, most powerful option for 48–72 h lanes.

How do you validate results and prove food safety?

Run a small ISTA 7E bench qualification with data loggers on your toughest lane. Tune dry-ice mass by ±10–20% based on warmest point and leftover ice at opening. Keep the report to satisfy marketplaces, carriers, and QA audits.

2025 developments and trends for frozen meat shipping

What’s new: The 2025 IATA dry-ice acceptance checklist standardizes counter checks; USPS Publication 52 keeps the 5 lb air cap; carriers emphasize UN 1845 + net kg and venting on labels. Ecommerce butchers are adopting VIP liners in hot lanes to cut ice mass while holding 72 hours.

Snapshot of the latest

-

Cleaner acceptance: Checklist-driven audits reduce relabels and delays.

-

VIP adoption: Less ice, smaller cube, better summer performance.

-

USPS clarity: Use private carriers for >5 lb by air; use USPS surface with “Surface Only.”

Frequently Asked Questions

How much dry ice for a 2–3 day box (10–15 lb payload)?

Plan 10–20 lb total (5–10 lb/day) in PUR; add 20–30% in summer. Record net kg on the box.

Can dry ice touch the meat?

No. Keep dry ice off food with inner cartons or spacers to prevent texture damage.

Do I need a Shipper’s Declaration?

Not when dry ice cools non-dangerous goods under PI 954; you still add UN 1845 and net kg to the air waybill.

What arrival temperature is safe?

Frozen or ≤ 40 °F at opening meets mail-order food safety guidance.

Is there a USPS limit for air?

Yes—5 lb per mailpiece. Use surface for larger charges or switch to UPS/FedEx air.

Summary & recommendations

A reliable dry ice pack for meat uses the 5–10 lb/day rule with a buffer, puts most ice on top, fills voids tight, and marks UN 1845 + net kg on vented packaging. Validate once with ISTA 7E and hold every delivery to frozen or ≤ 40 °F on arrival.

Next steps (do this now):

-

Map your hottest lane and choose EPS/PUR/VIP.

-

Use the estimator to set 24/48/72 h ice with a 20% buffer.

-

Update labels to UN 1845 + net kg; add Class 9; confirm venting.

-

Pilot two boxes with loggers; adjust ice by ±10–20%.

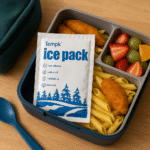

About Tempk

We design and qualify insulated shippers for frozen foods and life sciences. Our dry ice pack for meat kits pair right-sized EPS/PUR/VIP with clear packout photos, label templates, and validation support. Two advantages: fewer counter rejections and consistent 72-hour holds in hot lanes verified against ISTA 7E. Talk to a cold-chain specialist to right-size your next shipment.