How Much Does Each Dry Ice Pack Weigh and Will It Increase Shipping Costs Significantly?

When shipping temperature-sensitive products, dry ice is often necessary to ensure their safe transport. However, understanding how much dry ice weighs and how it affects shipping costs is essential for cost optimization. This guide explains the different dry ice pack sizes, the factors that influence shipping costs, and practical strategies to minimize expenses while adhering to the latest 2025 shipping regulations.

-

How much does each dry ice pack typically weigh?

-

How does dry ice weight affect shipping costs?

-

What are the best practices for minimizing shipping costs with dry ice?

-

What are the latest trends and regulations for 2025?

How Much Does Each Dry Ice Pack Weigh?

Dry ice pack weight varies based on shipment size, type of dry ice used, and the length of the shipment. On average, dry ice used in shipments weighs between 5 to 50 pounds. Smaller shipments may require only 5 pounds, while larger shipments can demand up to 50 pounds or more depending on factors such as the nature of the goods and transit duration.

Dry Ice Pack Sizes and Weights

Dry ice is typically available in three forms: blocks, pellets, and pucks. Each form has different weight characteristics and cooling durations:

| Type of Dry Ice | Weight Range | Common Use | Cooling Duration |

|---|---|---|---|

| Dry Ice Blocks | 5-25 pounds | Long-duration shipments | Up to 72 hours |

| Dry Ice Pellets | 1-10 pounds | Shorter shipments | 12-48 hours |

| Dry Ice Pucks | 5-10 pounds | Small shipments | 12-24 hours |

Tip: For long shipments, dry ice blocks are preferred, while pellets and pucks are more suited for smaller or shorter duration shipments.

Does Dry Ice Weight Impact Shipping Costs?

The weight of dry ice is a key factor in determining shipping costs. Carriers generally charge based on both the weight and the volume (dimensional weight) of the package. Here’s how dry ice impacts shipping costs:

Weight-Based Shipping Costs:

The heavier the dry ice, the higher the shipping cost. Heavier packages naturally incur higher charges, especially when the package exceeds weight thresholds.

Dimensional Weight Pricing:

In addition to actual weight, carriers may charge based on the volume of the package. Bulky packages containing dry ice may incur higher fees, even if they aren’t especially heavy.

Hazardous Materials Handling Fees:

Since dry ice is classified as a hazardous material, shipping carriers may apply additional handling fees, especially for international shipments that require special labeling, packaging, and documentation.

How Does Dry Ice Weight Affect Domestic vs. International Shipping?

The weight of dry ice can have a different impact on domestic and international shipments:

Domestic Shipping:

For domestic shipments, costs are generally determined by the weight and size of the package. Major carriers like UPS and FedEx have specific rates for shipments containing dry ice. Shipping costs can be influenced by the weight, size, and the type of service (overnight, ground, etc.).

International Shipping:

For international shipments, dry ice is classified as a dangerous good, which results in additional handling fees, special labeling, and paperwork. Furthermore, many international regulations limit the maximum weight of dry ice that can be shipped in one package, leading to higher overall costs.

Comparison of Costs for Different Shipping Types:

| Shipping Type | Cost Impact | Additional Charges |

|---|---|---|

| Domestic | Weight + Size | Possible fuel surcharges |

| International | Weight + Size + Dangerous Goods Fees | Special handling, documentation, labeling |

Can You Reduce Shipping Costs With Dry Ice?

Although dry ice can increase shipping costs, there are several strategies you can use to minimize these expenses:

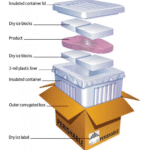

Optimized Packaging:

Using high-quality insulated packaging, such as vacuum-insulated panels (VIP), can significantly reduce the amount of dry ice required. Better insulation keeps the temperature stable for longer, reducing the need for excessive dry ice.

Efficient Sizing:

Ensure that you use the exact amount of dry ice needed. Overestimating can lead to unnecessary costs, while underestimating can risk product spoilage. Proper calculation based on the transit time and product weight is crucial.

Consolidate Shipments:

If possible, combine multiple smaller shipments into one larger package. This approach allows you to spread out the cost of dry ice and the shipping fee across several items, ultimately reducing per-item shipping costs.

Practical Example:

A company shipping temperature-sensitive food can minimize costs by using an insulated shipping container and choosing the correct amount of dry ice. This strategy ensures that the products remain safe without excess dry ice leading to higher shipping costs.

2025 Latest Trends in Dry Ice Shipping and Costs

Eco-Friendly Packaging:

The growing demand for sustainability in the logistics industry has led to innovations in eco-friendly packaging materials. Vacuum-insulated panels (VIP) offer superior insulation, reducing the need for large amounts of dry ice. These packaging materials not only lower costs but also help companies meet environmental goals.

Regulatory Changes and Compliance:

As of 2025, stricter regulations are being enforced on dry ice shipping, particularly for international shipments. Companies must adhere to new IATA and USPS regulations, which include better labeling and documentation requirements.

Alternative Cooling Solutions:

Phase-change materials (PCMs) are being introduced as a more sustainable alternative to dry ice. These materials provide cooling at specific temperatures and can reduce reliance on dry ice for certain types of shipments.

Market Insight:

The demand for dry ice shipping continues to grow with industries like pharmaceuticals and food delivery services. Innovations in packaging and sustainable practices are crucial to reducing the environmental impact of dry ice shipping.

Frequently Asked Questions (FAQ)

Q1: How do shipping companies charge for dry ice?

Shipping companies charge for dry ice based on its weight and size. Additionally, they may apply hazardous materials handling fees, particularly for international shipments.

Q2: Is dry ice considered a hazardous material?

Yes, dry ice is classified as a hazardous material due to its potential to displace oxygen and cause asphyxiation in confined spaces. Special packaging and handling are required for shipments containing dry ice.

Q3: How can I reduce the cost of dry ice shipping?

Optimize your packaging, use the right amount of dry ice, and consolidate shipments to reduce the overall cost. Efficient insulation and accurate calculations are key to minimizing unnecessary expenses.

Conclusion & Recommendations

Understanding the weight of dry ice and its impact on shipping costs is crucial for businesses that rely on temperature-sensitive products. By optimizing packaging, accurately calculating dry ice needs, and staying updated on 2025 regulations, you can ensure that your shipments are both safe and cost-effective.

Recommended Actions:

-

For Cost Efficiency: Use insulated packaging to reduce the amount of dry ice required.

-

For Domestic Shipments: Avoid overestimating dry ice needs and choose packaging that minimizes size.

-

For International Shipments: Be aware of hazardous material fees and comply with international regulations.

About Tempk

Tempk provides innovative solutions in cold chain logistics, specializing in temperature-controlled packaging and efficient shipping methods. We use advanced insulated materials to ensure your shipments remain safe and cost-effective while adhering to the latest regulatory standards.

Contact Tempk today to discuss how we can help optimize your dry ice shipping needs.