1) Why dry ice?

Dry ice (solid CO₂) sits at −78.5 °C (−109.3 °F) and sublimes—turns from solid straight to gas—absorbing a lot of heat as it goes (high enthalpy of sublimation ≈ 26 kJ/mol). That’s why it can hold deep‑frozen temps for days when paired with the right shipper.

Safety note: as it sublimates, 1 lb of dry ice produces ~250 L of CO₂ gas, which can quickly displace oxygen in closed spaces—vent every shipper and vehicle.

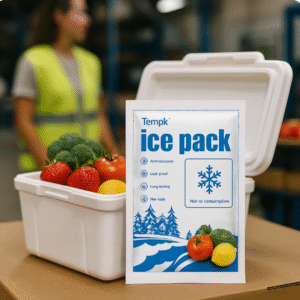

2) Pick the right containerr

| Container | Best for | Pros | Watch‑outs |

|---|---|---|---|

| EPS foam + carton | Economy frozen food, short routes | Low cost; easy to source | Bulky; lower R‑value than VIP; more dry ice needed |

| PUR / PIR foam | Longer routes, tighter temp control | Better insulation than EPS | More expensive; still bulky |

| VIP (vacuum insulated panel) shippers | High‑value biologics / long hauls | ~5× the thermal resistance per thickness vs conventional foams; smaller footprint | Cost; cannot be cut; handle carefully |

Why VIP matters: Typical VIP center‑of‑panel conductivity is around 0.004–0.008 W/(m·K), giving much higher R‑value per inch than EPS or PUR—hence smaller, lighter packs for the same hold time.

3) How much dry ice to use (for food & pharma)

Your needed load depends on duration, ambient temps, insulation type/thickness, load ratio (product+ice vs internal volume), and how often the box is opened. As a practical starting point for a closed parcel shipment:

-

Short‑haul (≤24 h): ~5–10 lb for a small EPS cooler (add more for hot lanes or larger volume).

-

48–72 h: scale linearly and prefer thicker EPS, PUR, or VIP to reduce weight.

-

>72 h or high heat lanes: move to VIP or split shipments to stay compliant and manageable.

Estimator (rule‑of‑thumb):Dry ice (lb) ≈ (Route days) × (container factor) × 6

-

container factor ≈ 1.0 (VIP), 1.3 (PUR), 1.6–2.0 (EPS); adjust +10–25% for >30 °C lanes.

Validate with a lane test or a small pilot before scaling. (The physics vary; this is a planning aid—not a certification.)

For aircraft safety planning (CO₂ buildup), FAA data pegs 1 lb → 8.8 ft³ of CO₂; operators use sublimation‑rate and air‑exchange calculations to set safe on‑board limits.

4) Step‑by‑step packout (works for food or specimens)

-

Pre‑chill: Freeze product solid; cool the shipper if possible.

-

Line & separate: Place a liner or corrugate between product and dry ice to avoid freezer burn.

-

Load order: Dry ice around and above product for top‑down cold; avoid only-bottom placement.

-

Fill voids: Minimize headspace with kraft/bubble (not airtight).

-

Vent: Do not tape the inner foam lid airtight; leave a vent path for CO₂.

-

Close outer carton firmly; shake test (no rattles).

-

Mark & label per section 5 (UN 1845, net kg, Class 9).

-

Drop‑off: Bring carrier checklist; declare dry‑ice weight on the air waybill.

These fundamentals refine the methods already present in your drafts while aligning to 2025 carrier guidance.

5) Labels, paperwork & rules (US, Air, Carriers)

Core regulations (quick reference)

-

49 CFR §173.217 (US DOT – aircraft/vessel):

Packages must permit CO₂ to vent; for aircraft, the net mass (kg) of dry ice must be marked on the outside; the shipper must arrange with the operator; special vessel markings apply. -

IATA (Air) – Packing Instruction 954 & acceptance checks:

Use the 2025 IATA Dry Ice Acceptance Checklist when a DG declaration isn’t required; PI 954 governs packagings and markings. (Typical carrier and university job aids reflect a 200 kg per‑package maximum for dry ice as refrigerant—always confirm operator variations). -

USPS (Mail):

Dry ice by air is limited to 5 lb per mailpiece; packaging must vent and conform to 49 CFR 173.217; surface mail may exceed 5 lb. See Packaging Instruction 9A and Section 743 for perishables.

Many labs note that dry ice isn’t regulated as hazmat for US ground (truck) shipments, though safe venting/marking is still essential.

Carrier checklists (what staff actually use)

-

FedEx: Mark “Dry ice” or “Carbon dioxide, solid,” UN 1845, net weight in kg, plus shipper/consignee addresses; affix Class 9 label; follow size rules for characters (e.g., 12 mm when >30 kg package capacity) and use the Dry Ice Job Aid (Jan 2025) and DG checklists at tender.

-

UPS: Use their coolants/refrigerants guidance; include amount of dry ice (or a statement that it’s ≤ 2.5 kg / 5.5 lb if allowed); never seal airtight; vent the shipper.

Label anatomy at a glance:

-

Text: Dry ice / Carbon dioxide, solid

-

UN: UN 1845

-

Hazard: Class 9 diamond (miscellaneous)

-

Quantity: Net dry ice (kg) (outside the Class 9 border)

-

Names/addresses: Shipper & Consignee on the package

6) Food safety notes (0 °F, refreezing)

-

Keep frozen food at 0 °F (−18 °C) or below; that’s the standard freezer target.

-

If a parcel arrives partly frozen or ≤ 40 °F (4 °C), it’s typically safe to refreeze or cook, though quality may drop—use a thermometer, not “feel.”

7) Troubleshooting & pro tips

-

Airtight box? If a lid “pops” or bulges, you’re trapping CO₂—repack with a vent path. (Remember 1 lb → ~250 L CO₂.)

-

Condensation soggy box? Add a poly liner or corrugate sleeve; never block vents.

-

Running warm early? Increase load ratio (more product mass relative to voids) and move dry ice above as well as around goods.

-

Lane hotter than expected? Switch to PUR/VIP or add a top “sacrificial” layer of dry ice.

-

CO₂ exposure: Work in ventilated areas; follow NIOSH limits (TWA 5,000 ppm; STEL 30,000 ppm).

8) FAQ

Q1) What’s the best dry ice packs and container for shipping food combo for 24–72 h?

For most frozen foods, EPS works up to a couple of days with enough dry ice; PUR gives you a margin; VIP keeps weight down for 3–5+ day routes. Pick based on lane temps and budget, then validate with a small test.

Q2) Can I ship dry ice internationally?

Yes, but air rules (IATA PI 954) and operator variations apply; expect destination‑country restrictions and carrier differences. Always clear with the carrier before tender.

Q3) How do I mark a box?

Write Dry ice (or Carbon dioxide, solid), UN 1845, net kg, plus shipper/consignee. Attach Class 9 label on the same side as the text when possible.

Q4) USPS vs. UPS/FedEx—what’s different?

USPS air caps dry ice at 5 lb per piece; UPS/FedEx follow IATA and their own job aids; ground rules differ.

Q5) Is dry ice allowed with gel packs?

Yes—just separate products from direct contact with dry ice (use corrugate/liners) and keep vents clear.

Q6) What’s UN 1845?

The UN number identifying dry ice in transport. You’ll print it on the package along with the net kg.