Best Dry Ice Ice Pack: How to Choose in 2025

Updated: October 13, 2025

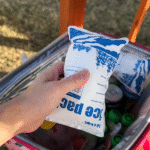

Finding the best dry ice ice pack starts with safety and ends with predictability. In the first box you pack, ensure venting, correct UN1845 labeling for air, and a fit that keeps goods frozen without ruptures or rework. You’ll lower losses, pass acceptance checks, and ship with confidence, lane after lane.

-

How does the best dry ice ice pack prevent bursts and pass checks?

-

How much dry ice or gel do you need for 24–72 hours?

-

Which materials, thicknesses, and vent paths work best on real lanes?

-

When is gel/PCM the better choice than dry ice for chilled targets?

-

What 2025 innovations matter: smart vents, mono-materials, and digital validation?

What makes the best dry ice ice pack safer and compliant?

Short answer: Venting, fit, and durability. The best dry ice ice pack always includes a controlled vent path, uses a bag that fits the block or pellets without over-sealing, and survives drops and vibration in automation. Packages must not be airtight, and inner bags are folded, not sealed—a pass/fail detail on acceptance checklists.

Why this matters to you: Dry ice sublimes and produces gas. A sealed bag traps pressure and can rupture, damage the shipper, or fail acceptance. The safest standard pack uses vent-friendly inner bags and a vented outer shipper, marked UN1845 with net weight for air. That one change reduces rework and claims dramatically on frozen lanes.

Material choices for the best dry ice ice pack

| Material | Barrier | Vent behavior | Durability | What it means for you |

|---|---|---|---|---|

| HDPE 5–6 mil | Medium | Balanced | High | Robust in automation, good all-rounder. |

| LDPE 4–5 mil | Med-low | Good | Flexible | Easier handling; still needs fold-vent. |

| Metallized/mylar | High | Low without vents | Very high | Use only with micro-vents or fold gaps. |

| Kraft + PE laminate | Medium | Naturally vented | Moderate | Eco-led choice; great for pellets/blocks. |

Practical tips you can apply today

-

Fold, don’t seal any inner bag holding dry ice.

-

Keep a clear headspace channel from inner bags to the shipper’s vent/plug.

-

Mark air shipments “Carbon dioxide, solid (UN1845)” with net kg.

-

Train teams with the phrase “package is vented.”

Real-world case: A national food brand switched from sealed film sleeves to folded HDPE bags plus a vented cooler. They cut ruptures and rework while improving on-time delivery by double digits on summer lanes.

How much of the best dry ice ice pack do you need?

Short answer: Start with a lane-based rule of thumb and then validate. For frozen lanes, plan roughly 5–10 lb per 24 hours per shipper, depending on insulation and ambient. For chilled (0–8 °C), use gel/PCM sized by hours and heat load; you don’t need UN1845 for gel-only shippers.

Expand: Blocks outlast pellets because of lower surface area, so choose blocks for long holds and pellets for fast pull-down plus top-off. Always split the total mass into six positions (bottom/sides/top) to stabilize temperatures and preserve vent paths. Log and tune by season.

Sizing rules for 24–72 hours (start here)

| Target | Typical packout | Planning mass | What to adjust |

|---|---|---|---|

| 24 h frozen | 2 bottom, 2 sides, 2 top | ~5–10 lb total | Add foam cap; ensure vent path. |

| 48 h frozen | Six-point with blocks | ~10–20 lb | Prefer blocks over pellets. |

| 72 h frozen | Six-point + liner | ~20–30 lb | Upgrade insulation before mass. |

| 24–48 h chilled | 6 gel bricks (600–900 g) | 4–6 units | Step up to higher-latent PCMs for heat. |

Hands-on estimator (optional embed)

Best dry ice ice pack vs gel pack—when should you choose each?

Direct answer: Use the best dry ice ice pack (real dry ice in vented packaging) for frozen targets. Use gel/PCM packs for 0–8 °C. Many online “dry ice ice pack” listings mean gel/PCM and are not regulated like CO₂. Pick by temperature first, then fit and compliance.

Context: Dry ice demands vented bags and a vented outer shipper with UN1845 marks for air. Gel/PCM requires none of that, but it cannot keep goods frozen. Avoid mixing unless you flip to the dry-ice SOP.

Comparison at a glance

| Goal | “Best” choice | Why | Watch-outs | For you |

|---|---|---|---|---|

| Keep goods frozen | Best dry ice ice pack (vented inner + vented shipper) | Strongest frozen hold | Never seal plastic bags; leave vents open | Fewer failures on long lanes. |

| Keep goods 0–8 °C | Gel/PCM bricks | Simple training; no UN1845 | Won’t hold frozen | Lower ops burden; faster packing. |

Best dry ice ice pack packouts that pass checks (24–72 h)

Short answer: The most forgiving pattern is the six-point packout—two bottom, two sides, two top—plus a clear headspace channel to the shipper’s vent or drain. Inner bags are folded, not sealed. Label UN1845 with net kg for air shipments.

How to build it

-

Weigh & split the total CO₂ (rule of thumb above).

-

Bag correctly: kraft sacks or folded film; don’t heat-seal.

-

Place 2 bottom, 2 sides, 2 top around the payload (no direct contact with primaries).

-

Add foam cap and maintain a vent channel to the cooler’s plug/vent.

-

Check labels and acceptance items (e.g., “package is vented”).

Durability tests that save claims

| Test | Target | Your benefit |

|---|---|---|

| Drop (1.2 m) | No rupture | No contamination, fewer re-packs. |

| Pressure rise | ≤0.2 bar | Confirms safe CO₂ escape. |

| 100+ picks | No tearing | Automation-ready. |

| Humidity/low-temp | No cracking | Holds up at −78 °C. |

2025 trends for the best dry ice ice pack

What’s new: Smart vent films, recyclable mono-materials, carbon-tracked batches, and AI-assisted sublimation modeling help you ship safer and greener without adding labor. These innovations redefine what “best” means this year.

Latest at a glance

-

Smart vents: Pores that open under pressure cut burst risk on air lanes.

-

Mono-material packs: Easier recycling and cleaner ESG reporting.

-

Digital CO₂ tracing: QR batches feed Scope-3 audits.

Market insight: Shippers standardize around vented configurations and checklist language (“package is vented”) to speed acceptance and training—a small documentation change that yields outsized compliance wins.

Frequently Asked Questions

Q1: What’s the single most important feature of the best dry ice ice pack?

A controlled vent path—folded inner bag plus a vented outer shipper. That’s the core of safety and acceptance.

Q2: Can I heat-seal a film bag to contain chips?

No. Do not place dry ice in sealed plastic bags. Fold the mouth or use kraft sacks so CO₂ can escape.

Q3: Gel packs vs the best dry ice ice pack—how do I choose?

Pick by target temperature: gel/PCM for 0–8 °C; dry ice for frozen. Then size mass and choose materials for your lane.

Q4: How much dry ice for 48 hours?

Start around 10–20 lb, prefer blocks, then test with data loggers and adjust by season.

Q5: What labels are required for air?

Mark “Carbon dioxide, solid (UN1845)” with the net weight and ensure the package is vented.

Summary & Recommendations

Recap: The best dry ice ice pack is a vented configuration that keeps goods frozen without sealing CO₂, uses materials that survive handling, and follows UN1845 and acceptance language. Right-size dosing with six-point layouts, then validate and document.

Next steps:

-

Map lane time and ambient; 2) Choose pack type (dry ice vs gel); 3) Set venting and labels; 4) Pilot and log; 5) Standardize SOPs; 6) Review ESG and recyclability. Need a one-page SOP or lane sizing? Contact our team.

About Tempk

We design and validate cold-chain packaging for performance and sustainability. Our portfolio spans HDPE, metallized, and kraft-laminate options with engineered vents, plus gel/PCM solutions for chilled lanes—all validated for real-world logistics. We help 3PLs and shippers reduce waste, prevent ruptures, and meet ESG targets. Talk to our engineers for a lane-specific spec.